Novelbridge crane beam bearing platform structure of underground power house and construction method of novel bridge crane beam bearing platform structure

A technology for underground workshops and load-bearing platforms, which is applied in the direction of basic structure engineering, truss structures, joists, etc., to achieve the effects of increased stability, increased contact area, and improved mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

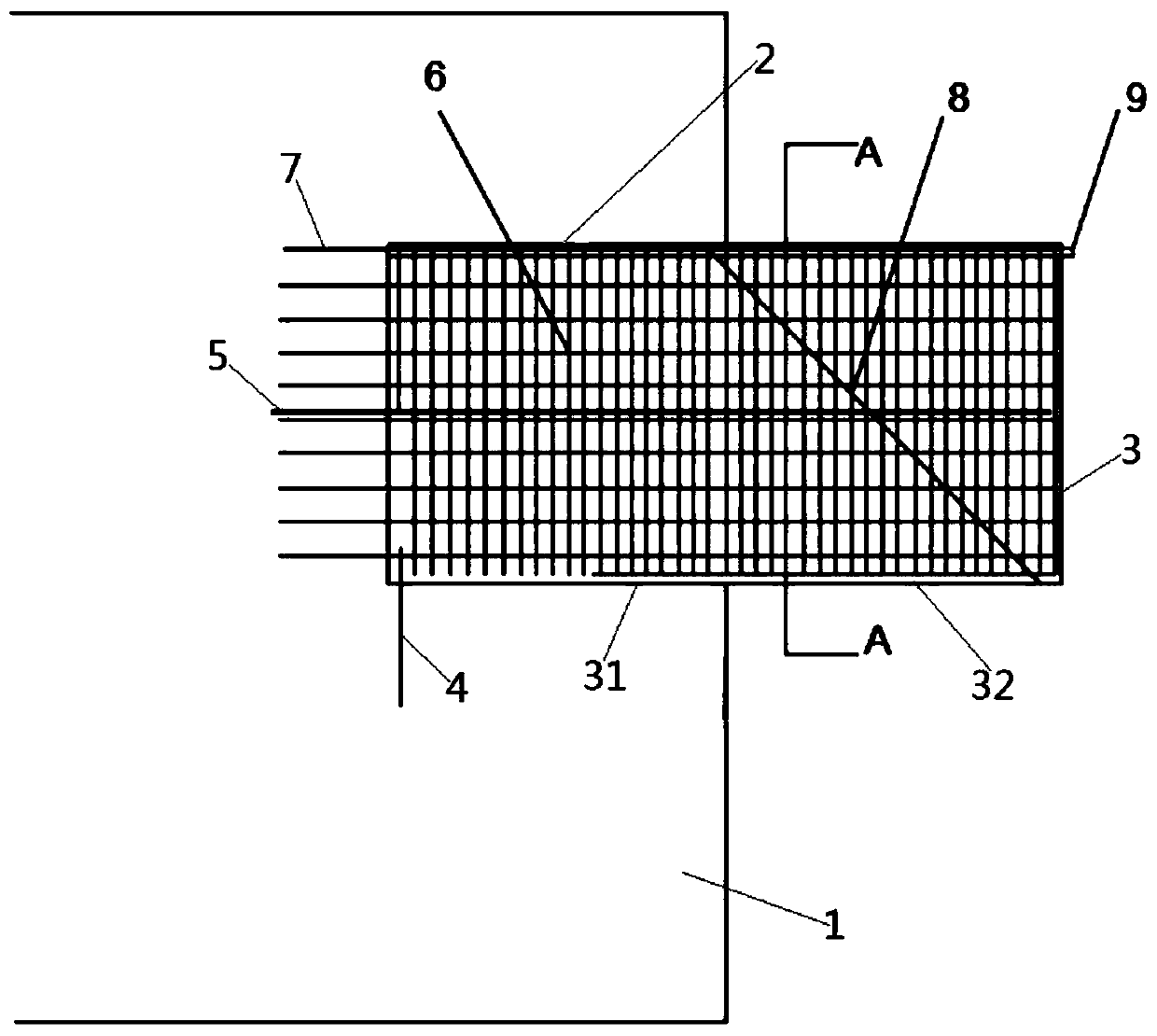

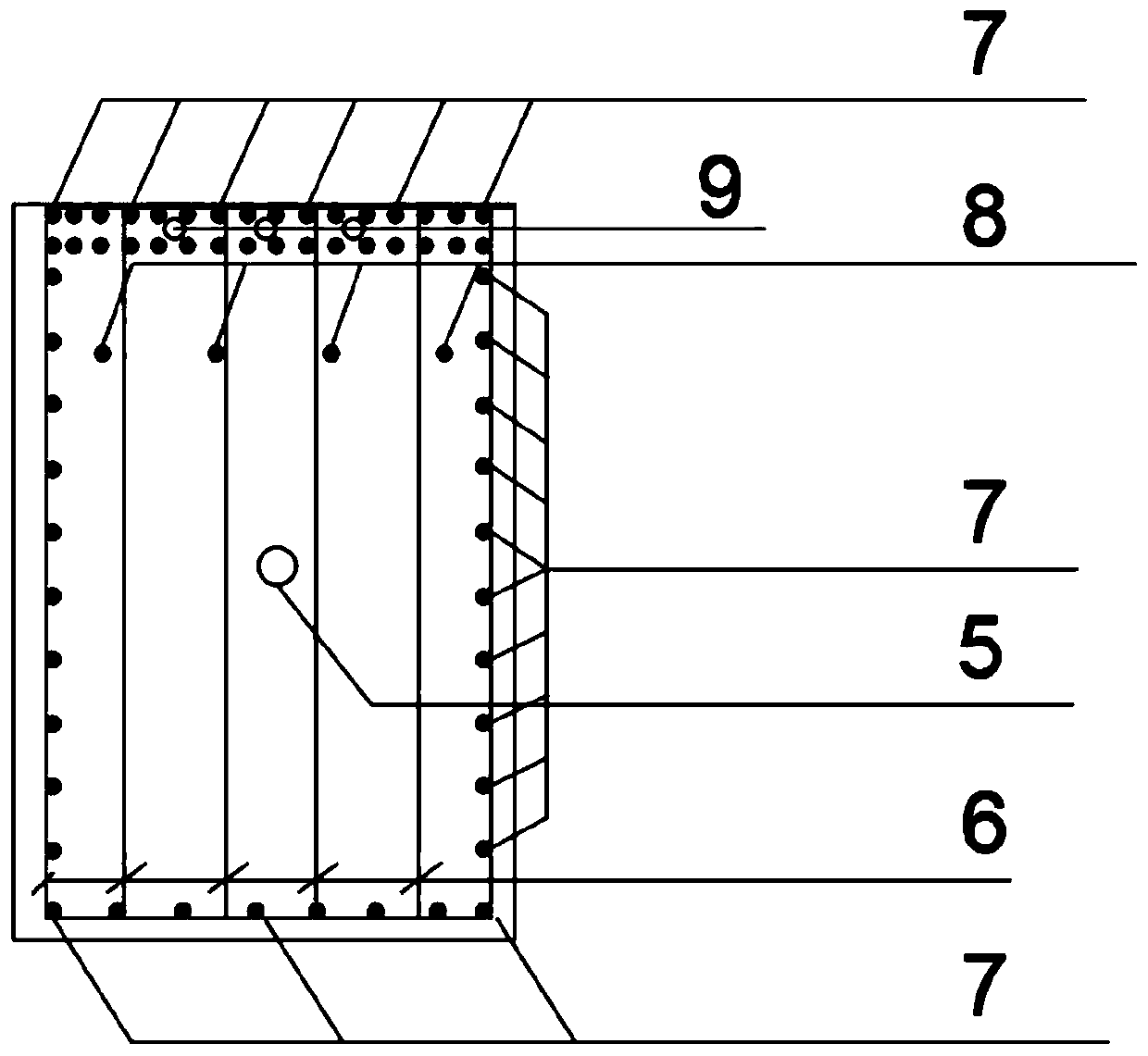

[0030] Such as figure 1 As shown, the present invention provides a novel underground powerhouse bridge crane beam bearing platform structure, including a cantilever beam 3, the cantilever beam 3 is divided into an embedded section 31 and a cantilever section 32, and the cantilever beam is determined according to the most unfavorable load borne by the cantilever beam 3 3, according to the section form and embedding depth, the embedding groove 2 is excavated in the rock mass 1. Specifically, the most unfavorable load consists of dead load (mainly including cantilever beam) and live load (mainly including bridge machine and hoisting equipment), calculate the maximum shear force, bending moment and torque by load combination, preset the section form and embedding depth of the most unfavorable load, carry out reinforcement calculation according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com