UHMWPE fiber reinforced resin-based soft bulletproof material

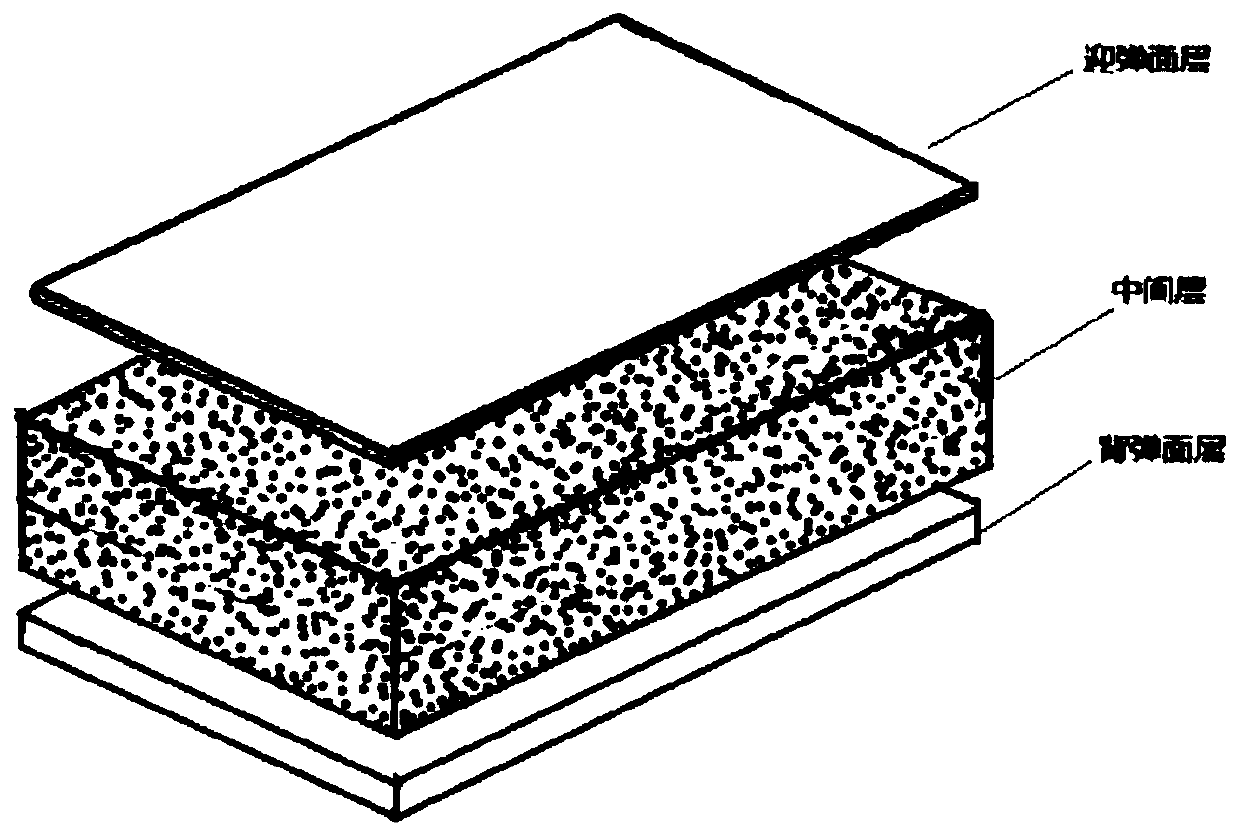

A fiber-reinforced resin and soft technology, which is applied in the field of UHMWPE fiber-reinforced resin-based soft bulletproof materials, can solve the problems that the ballistic resistance needs to be improved and the depth of back convexity is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] UHMWPE (linear density 800D) fibers are made into plain weave (area density 190g / m 2 ), and then the plain weave and PE hot-melt resin film (area density 40g / m 2 ) in the form of "1 layer of adhesive film + 1 layer of plain weave + 1 layer of adhesive film" to make a woven single-layer material by hot pressing. The temperature of hot pressing is 130°C, the time is 0.5h, and the pressure is 2MPa; The surface density of the single layer material is 270g / m 2 ;

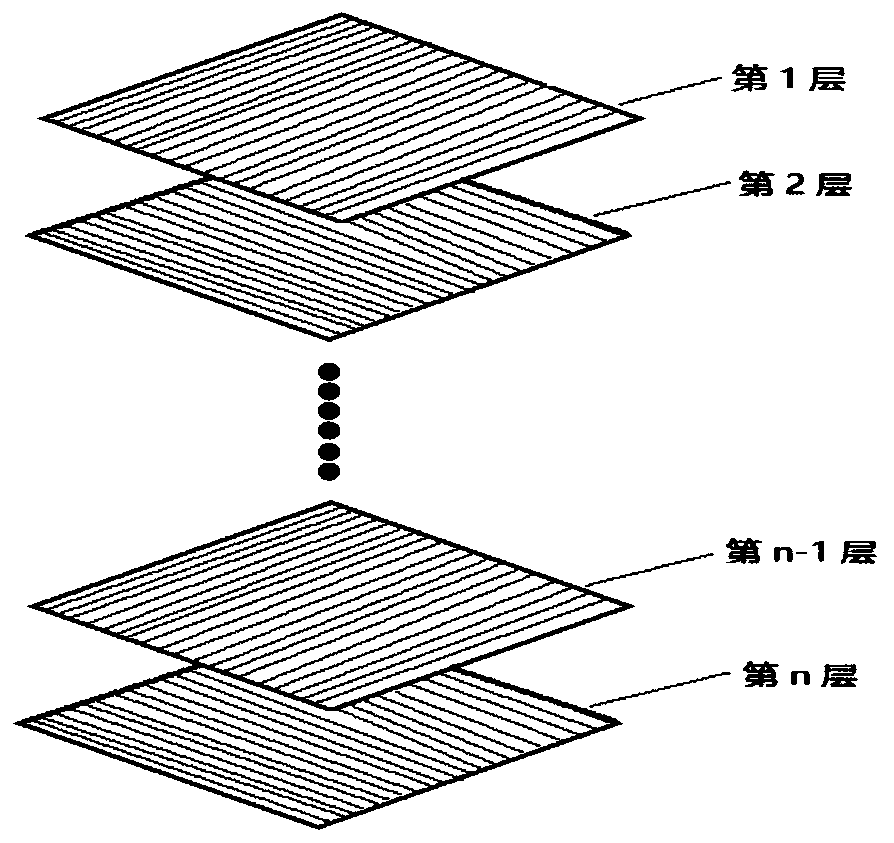

[0038] UHMWPE fiber (linear density 800D) and thermoplastic resin (PU) with a mass ratio of 4:1 are made into a UD single piece according to the UD cloth molding method, and the surface density of the UD single piece is 40g / m 2 , superimpose 4 layers of UD monolithic sheets in the order of 0°→90°→0°→90°→... to obtain a UD sheet by hot pressing. The temperature of hot pressing is 120°C, the time is 0.5h, and the pressure is 2 MPa;

[0039] One layer of woven single-layer material is used as the upper surface lay...

Embodiment 2

[0045] UHMWPE (linear density 800D) fibers are made into plain weave (area density 190g / m 2 ), and then the plain weave and PE hot-melt resin film (area density 40g / m 2 ) in the form of "1 layer of adhesive film + 1 layer of plain weave + 1 layer of adhesive film" to make a woven single-layer material by hot pressing. The temperature of hot pressing is 130°C, the time is 0.5h, and the pressure is 2MPa; The surface density of the single layer material is 270g / m 2 ;

[0046] UHMWPE fiber (linear density 800D) and thermoplastic resin (PU) with a mass ratio of 4:1 are made into a UD single piece according to the UD cloth molding method, and the surface density of the UD single piece is 40g / m 2 , superimpose 4 layers of UD monolithic sheets in the order of 0°→90°→0°→90°→... to obtain a UD sheet by hot pressing. The temperature of hot pressing is 120°C, the time is 0.5h, and the pressure is 2 MPa;

[0047] One layer of woven single-layer material is used as the upper shell layer...

Embodiment 3

[0050] UHMWPE (linear density 800D) fibers are made into plain weave (area density 190g / m 2 ), and then the plain or twill fabric and PE hot-melt resin film (area density 40g / m 2 ) in the form of "1 layer of adhesive film + 1 layer of plain weave + 1 layer of adhesive film" to make a woven single-layer material by hot pressing. The temperature of hot pressing is 130°C, the time is 0.5h, and the pressure is 2MPa; The surface density of the single layer material is 270g / m 2 ;

[0051] UHMWPE fiber (linear density 800D) and thermoplastic resin (PU resin) with a mass ratio of 4:1 are made into a UD single piece according to the UD cloth molding method, and the surface density of the UD single piece is 40g / m 2 , superimpose 4 layers of UD monolithic sheets in the order of 0°→90°→0°→90°→... to obtain a UD sheet by hot pressing. The temperature of hot pressing is 120°C, the time is 0.5h, and the pressure is 2 MPa;

[0052] Two layers of woven single-layer materials are superimpos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com