Three-dimensional carbon fiber prefabricated part enhanced yttrium oxide-zirconium oxide multiphase ceramic composite material and preparation method thereof

A technology of three-dimensional carbon fiber and composite ceramics, which is applied in the field of fiber-reinforced ceramic matrix composites, can solve the problems of unsatisfactory deposition characteristics and no three-dimensional carbon fiber prefabricated composite ceramic composite materials, and achieve excellent oxidation resistance and excellent mechanical properties. performance, the effect of overcoming brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

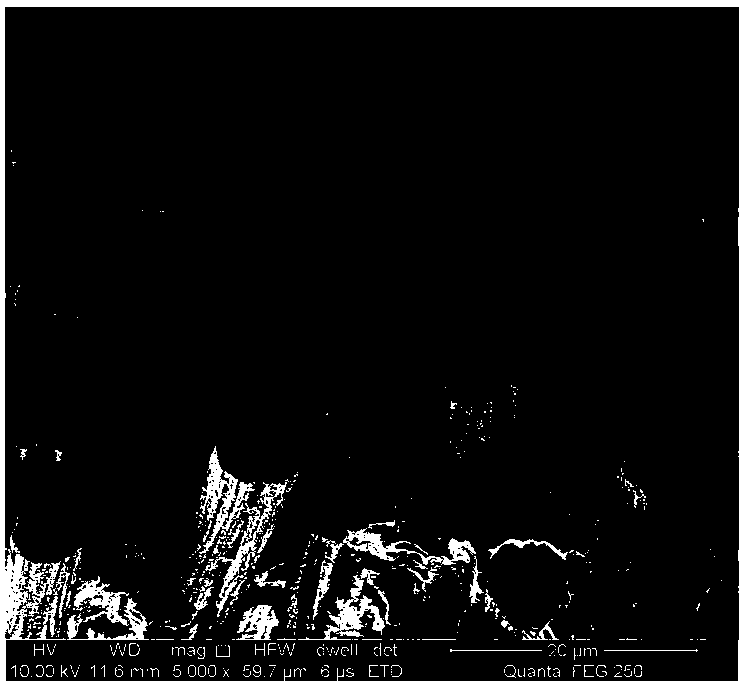

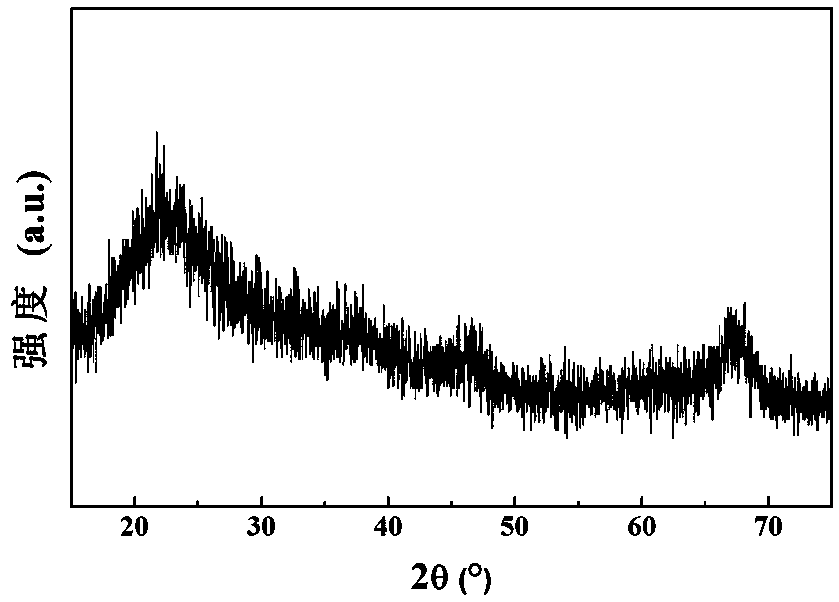

[0042] A kind of three-dimensional carbon fiber prefabricated part reinforced Y of the present invention 2 o 3 -ZrO 2 Multiphase ceramic composites, including 3D carbon fiber preforms and Y 2 o 3 -ZrO 2 Composite ceramics, where Y 2 o 3 -ZrO 2 Composite ceramics as matrix, 3D carbon fiber prefabricated parts as reinforcing phase, Y 2 o 3 -ZrO 2 Composite ceramics are uniformly filled in the voids of three-dimensional carbon fiber preforms, Y 2 o 3 -ZrO 2 In the composite ceramic matrix, Y 2 o 3 / ZrO 2 The molar ratio of is 1:1, in this embodiment, the three-dimensional carbon fiber preform reinforced Y 2 o 3 -ZrO 2 The porosity of the multiphase ceramic composite is 12.4%.

[0043] In this embodiment, the three-dimensional carbon fiber prefabricated part is a three-dimensional carbon fiber prefabricated part obtained by stacking and sewing carbon fiber cloth, and the volume fraction of fibers in the three-dimensional carbon fiber prefabricated part is 48%.

...

Embodiment 2

[0055] A kind of three-dimensional carbon fiber prefabricated part reinforced Y of the present invention 2 o 3 -ZrO 2 Multiphase ceramic composites, including 3D carbon fiber preforms and Y 2 o 3 -ZrO 2 Composite ceramics, where Y 2 o 3 -ZrO 2 Composite ceramics as the matrix, ZrO 2 The molar content in the composite ceramics is 5%, the three-dimensional carbon fiber preform is the reinforcing phase, Y 2 o 3 -ZrO 2 The multi-phase ceramics are evenly filled in the gaps of the three-dimensional carbon fiber preform. In this embodiment, the three-dimensional carbon fiber preform is reinforced by Y 2 o 3 -ZrO 2 The porosity of the multiphase ceramic composite is 8.8%.

[0056] In this embodiment, the three-dimensional carbon fiber preform is a three-dimensional four-way braided three-dimensional carbon fiber preform, and the volume fraction of fibers in the three-dimensional carbon fiber preform is 53%.

[0057] In this example, the three-dimensional carbon fiber pr...

Embodiment 3

[0068] A kind of three-dimensional carbon fiber prefabricated part reinforced Y of the present invention 2 o 3 -ZrO 2 Multiphase ceramic composites, including 3D carbon fiber preforms and Y 2 o 3 -ZrO 2 Composite ceramics, where Y 2 o 3 -ZrO 2 Composite ceramics as the matrix, ZrO 2 The molar content in composite ceramics is 95%, and the three-dimensional carbon fiber preform is the reinforcing phase, Y 2 o 3 -ZrO 2 Composite ceramics are evenly filled in the gaps of the three-dimensional carbon fiber preform. In this embodiment, the three-dimensional carbon fiber preform is reinforced by Y 2 o 3 -ZrO 2 The porosity of the multiphase ceramic composite is 14.3%.

[0069] In this embodiment, the three-dimensional carbon fiber preform is a three-dimensional carbon fiber preform with a two-dimensional semi-woven structure, and the volume fraction of fibers in the three-dimensional carbon fiber preform is 46%.

[0070] In this example, the three-dimensional carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com