Light-weight large-load commercial vehicle stabilizer bar and suspender assembly and preparation method thereof

A commercial vehicle and stabilizer bar technology, applied in vehicle components, interconnection systems, suspensions, etc., can solve the problem that the stabilizer bar boom assembly cannot meet the lightweight effect at the same time, cannot meet the high-load application scenarios, and cannot be mass-produced. exchange and other issues, to achieve the effect of improving the ultimate failure strength, high degree of freedom in shape design, and high designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

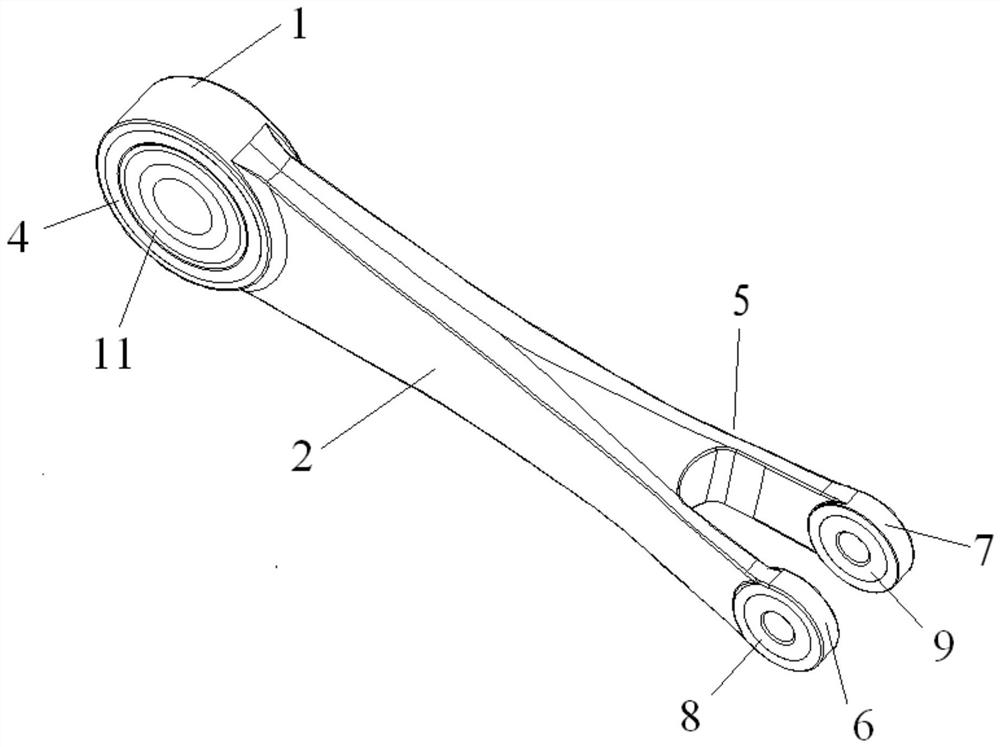

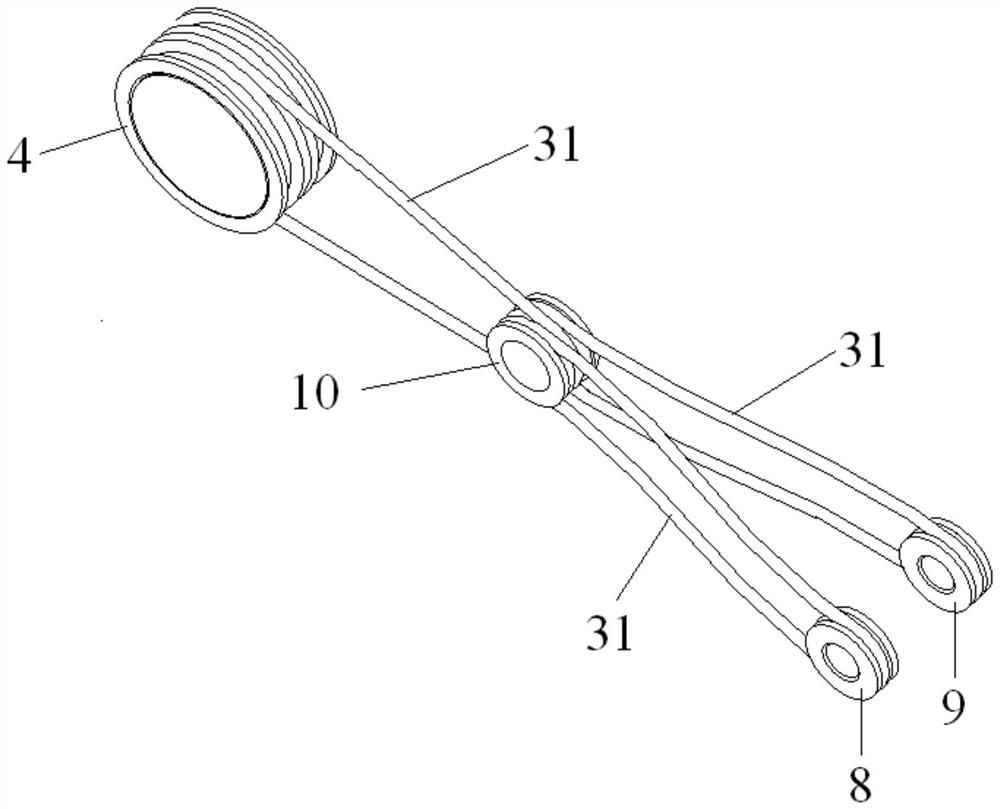

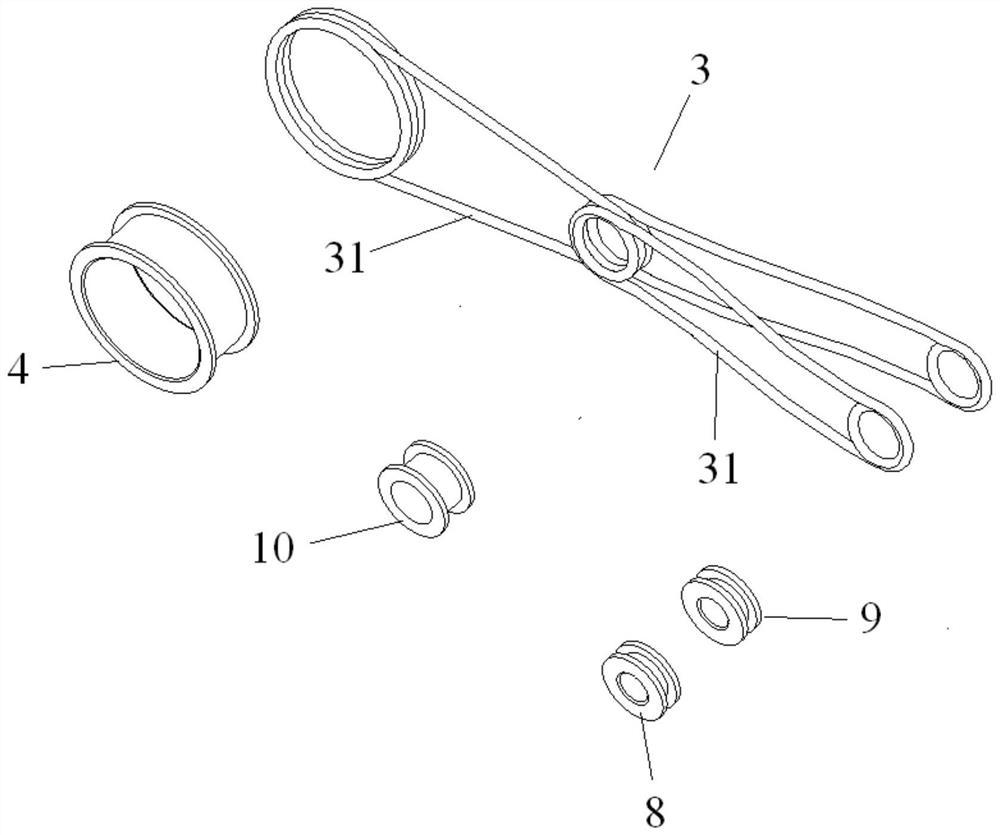

[0044] A light-weight and heavy-duty commercial vehicle stabilizer bar suspension rod assembly of the present invention, such as Figure 1 to Figure 4 As shown, it includes a composite material rod body 2 and a reinforcement body 3, the reinforcement body 3 includes a plurality of reinforcement body segments 31, one end of the composite material rod body 2 is provided with a first sleeve 1, and a first bushing is provided inside the first sleeve 1 4. The other end of the composite material rod body 2 is provided with a connecting fork 5, and the ends of the two tines of the connecting fork 5 are respectively provided with a second sleeve 6 and a third sleeve 7, and the second sleeve 6 is provided with a first Two bushings 8, the third bushing 7 is provided with a third bushing 9, the composite rod body 2 is provided with a fourth bushing 10 in the middle along the length direction of the rod body, the first bushing 4 and the fourth bushing 10 A reinforcement segment 31 is woun...

Embodiment 2

[0054] A light-weight and heavy-duty commercial vehicle stabilizer bar suspension rod assembly of the present invention, such as Figure 1 to Figure 4 As shown, it includes a composite material rod body 2 and a reinforcement body 3, the reinforcement body 3 includes a plurality of reinforcement body segments 31, one end of the composite material rod body 2 is provided with a first sleeve 1, and a first bushing is provided inside the first sleeve 1 4. The other end of the composite material rod body 2 is provided with a connecting fork 5, and the ends of the two tines of the connecting fork 5 are respectively provided with a second sleeve 6 and a third sleeve 7, and the second sleeve 6 is provided with a first Two bushings 8, the third bushing 7 is provided with a third bushing 9, the composite material rod body 2 is provided with two fourth bushings 10 along the length direction of the rod body, the first bushing 4 and the adjacent fourth bushing A reinforcing body segment 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com