Hot-casting anchoring method of stainless steel cables

An anchoring method, cable heating technology, applied to heat exchange equipment, rotors, cylinders, etc., can solve problems such as insufficient connection and failure to ensure effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the new features and technical content of the invention, please refer to the following detailed description and drawings of the new invention. However, the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

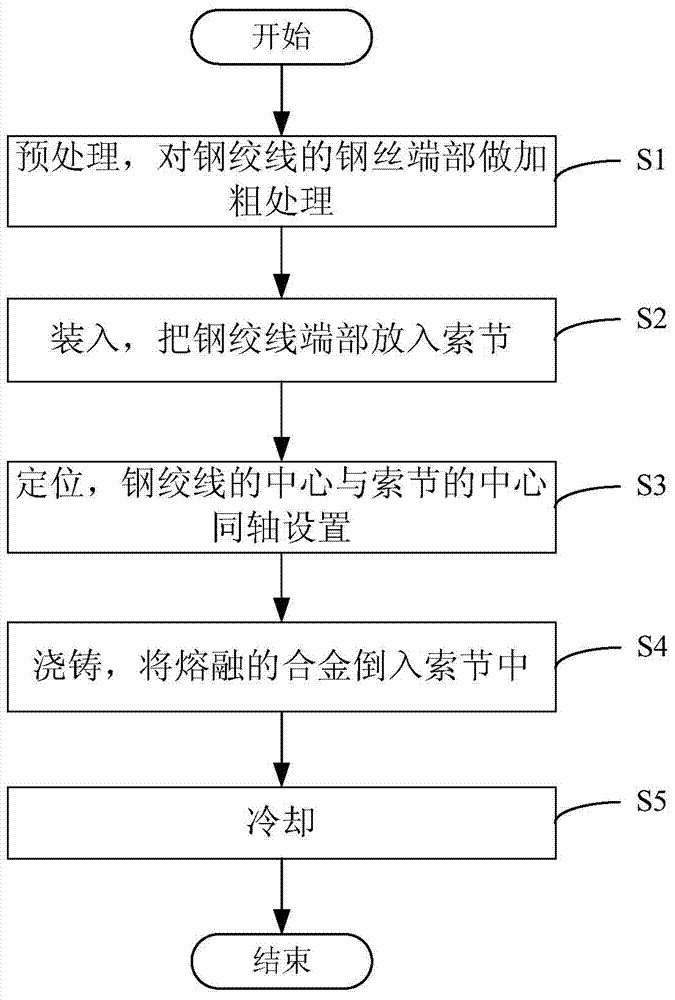

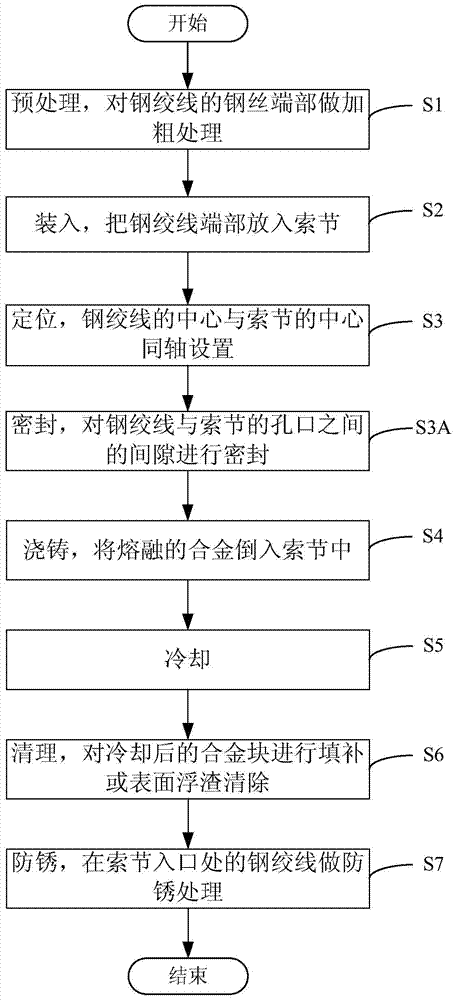

[0023] combined with Figure 1~6 , in the first embodiment, the stainless steel cable hot casting anchoring method includes:

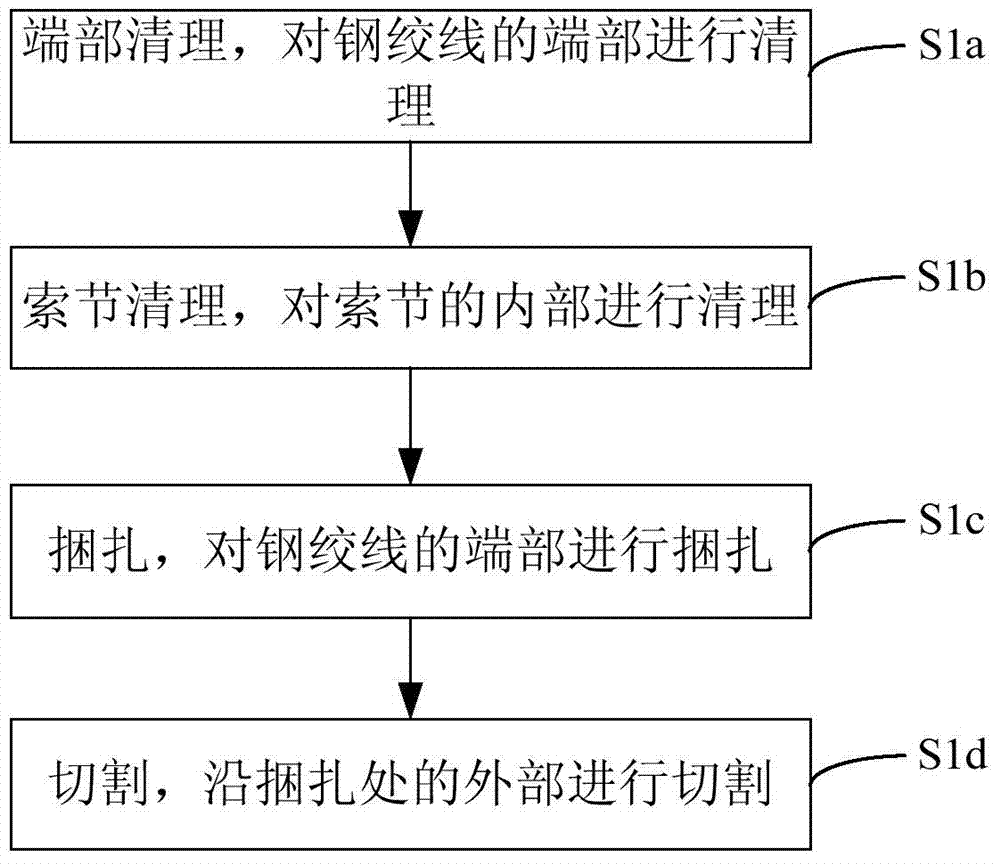

[0024] SET1: Pretreatment, thickening the steel wire end 30 of the steel strand 10 . Specifically, the steel strand 10 is formed by winding steel wires in a certain way, for example, a 7-wire steel strand 10 . The local position of the end portion 30 of the steel wire, that is, the topmost part, is thickened, and can be thickened into a spherical shape, a rectangle, or the like. Further, the wire end 30 can be thickened by welding; in addition, the thickening can be done by cold heading or hot heading.

[0025] SET2: Loading, putting the end 30 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com