Squirrel Cage Elastic Support with Stiffness Gradient

An elastically supported, squirrel-cage technology, used in engine lubrication, turbine/propulsion lubrication, gas turbine installations, etc., can solve problems such as easy fracture of cage bars, achieve non-breakage, improve load bearing and bending moment capacity, The effect of facilitating marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

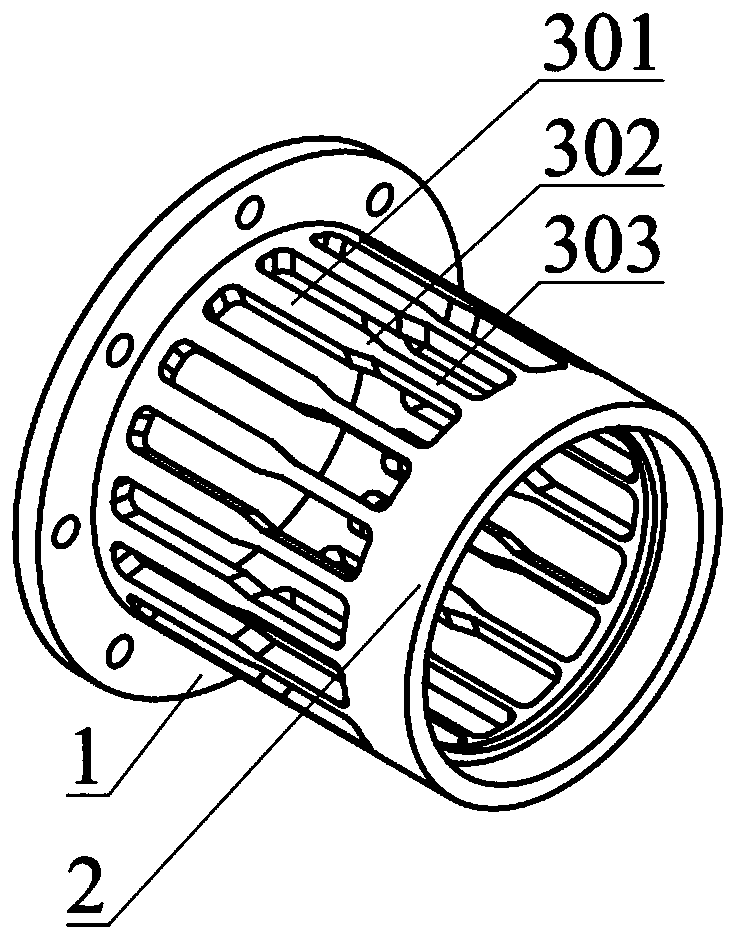

[0018] Such as figure 1 As shown, a squirrel-cage elastic support with a gradient of stiffness in the present invention includes a fixed ring 1 and a cylindrical bearing mounting ring 2, and the fixed ring 1 and the cylindrical bearing mounting ring 2 are integrally formed. Several through grooves are provided on the cylinder wall of the cylindrical bearing mounting ring 2, correspondingly forming several evenly distributed cage bars with variable cross-sections. The variable-section cage includes a first cage part 301 near one end of the fixed ring 1, a second cage part 303 away from the end of the fixed ring 1, and a first cage part 301 and a second cage part 302 for connecting the transition, And it has a transitional cage part 302 with a gradually changing section. In the present invention, the cross-sectional area of the first cage part 301 is larger than the cross-sectional area 303 of the second cage part, and the two sides of the transitional cage part 302 are trans...

Embodiment 2

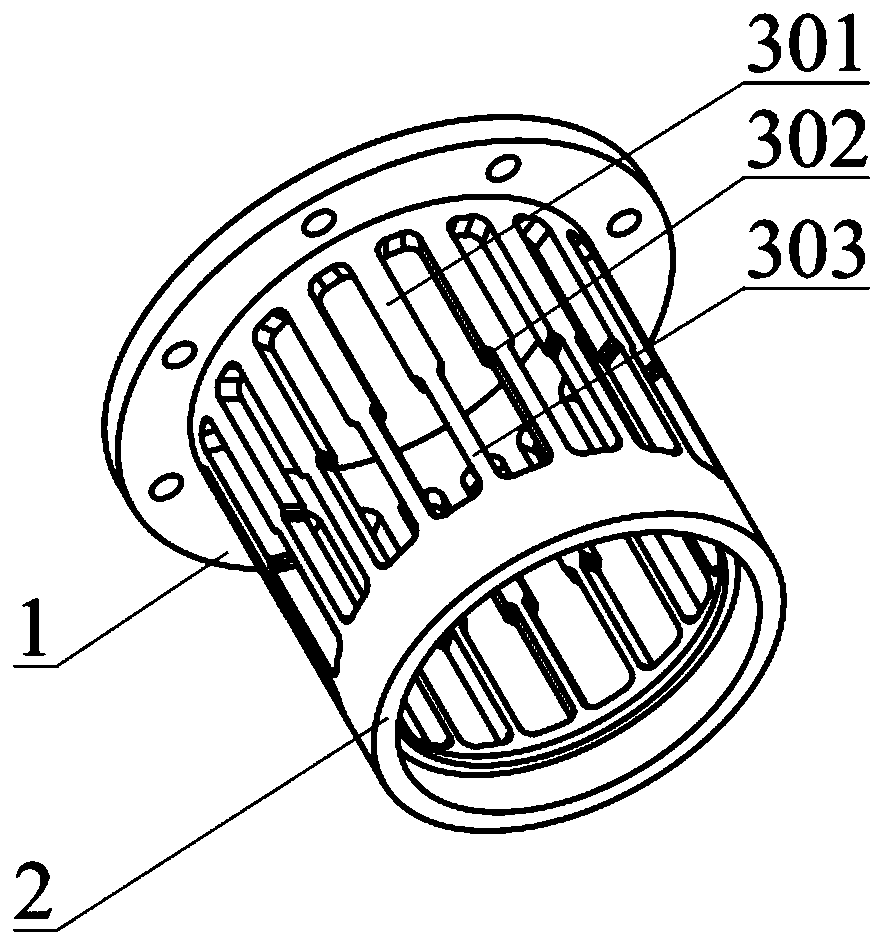

[0020] Such as figure 2 As shown, a squirrel-cage elastic support with a gradient of stiffness in the present invention includes a fixed ring 1 and a cylindrical bearing mounting ring 2, and the fixed ring 1 and the cylindrical bearing mounting ring 2 are integrally formed. Several through grooves are provided on the cylinder wall of the cylindrical bearing mounting ring 2, correspondingly forming several evenly distributed cage bars with variable cross-sections. The variable section cage includes a first cage part 301 near the end of the fixed ring 1, a second cage part 303 away from the end of the fixed ring 1, and a transitional connection between the first cage part 301 and the second cage part 303, And it has a transitional cage part 302 with a gradually changing section. In the present invention, the cross-sectional area of the first cage part 301 is greater than the cross-sectional area 303 of the second cage part, and the two sides of the transitional cage part 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com