Gear and thin-wall disc combined type coupling

A combined, coupling technology, applied in the direction of coupling, elastic coupling, mechanical equipment, etc., can solve the problems that the rotation speed cannot meet the requirements, the coupling requirements are urgent, etc., and achieve small acting torque and force, The effect of high speed and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

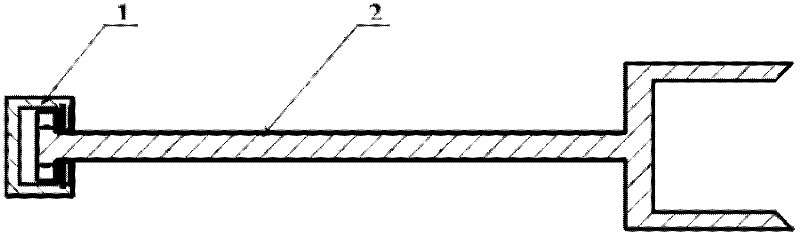

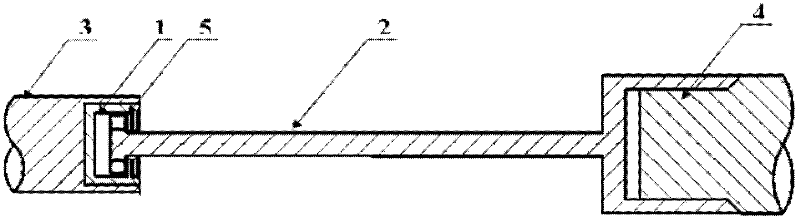

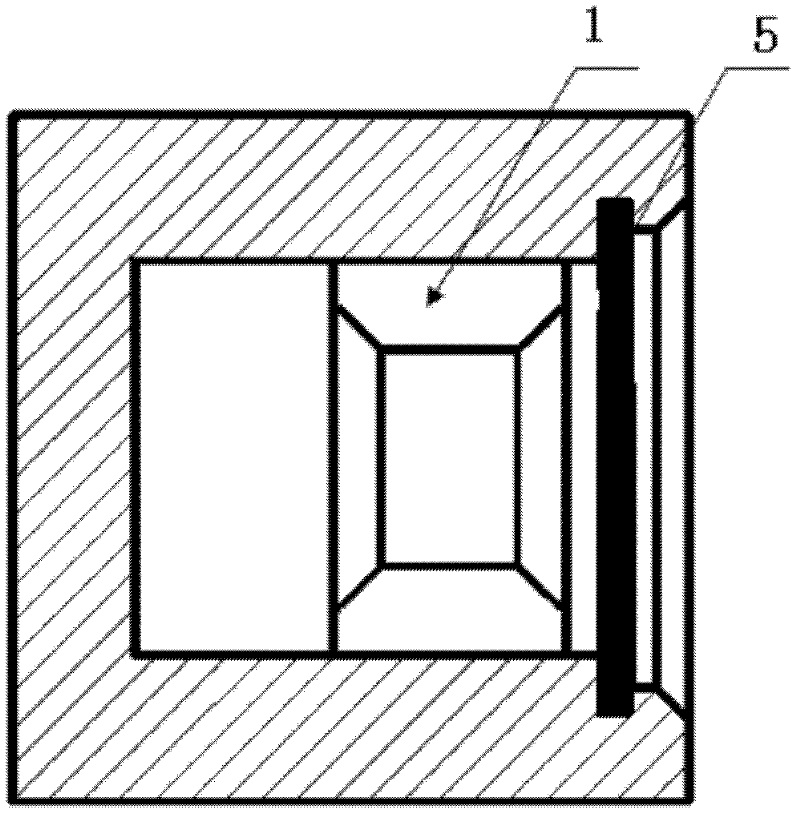

[0020] see figure 1 , figure 2 and image 3 , a gear-thin-walled disc combined coupling, including an inner gear 1, the inner gear of the inner gear 1 is connected to the outer gear sleeve at the beginning of the intermediate shaft 2, and the inner gear 1 is cold-pressed or shrink-fitted Cooperate with the end of the torque input shaft 3, the cylindrical thin wall on the thin disc at the end of the intermediate shaft 2 is interference fit with the initial end of the torque output shaft 4, the starting end and the end of the intermediate shaft 2 are connected by a thin rod, and the internal teeth The gear meshing between the internal teeth of the ring 1 and the external gear sleeve of the intermediate shaft 2 is lubricated by a lubricating sealing device 5 .

[0021] The tooth shape of the outer gear bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com