Small turbine engine rotor bearing and lubricating integrated structure

A technology of turbine engine and rotor support, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of cumbersome lubrication system and complex structure, and achieve the effect of enhancing heat exchange effect, ensuring smooth operation and stable elastic support effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

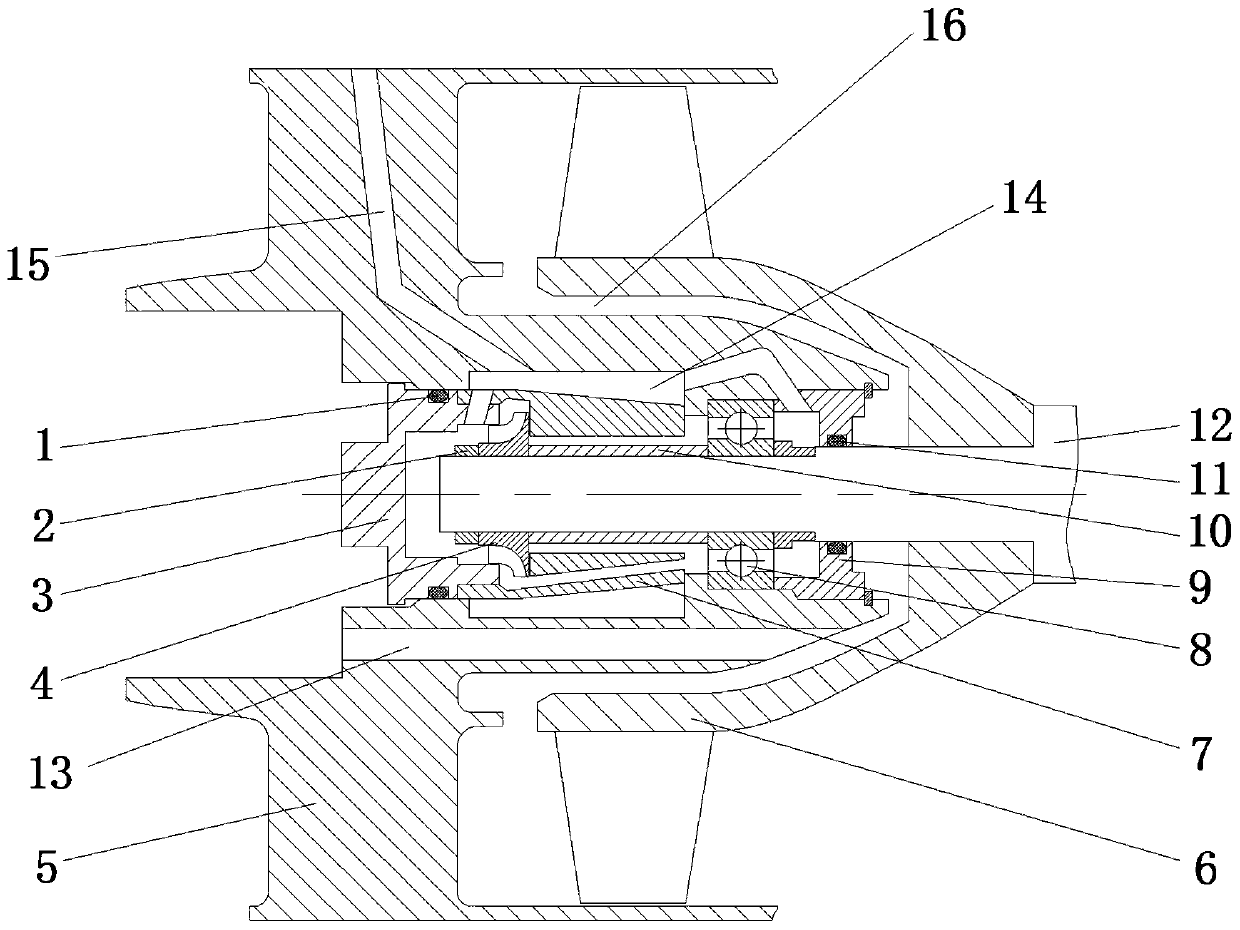

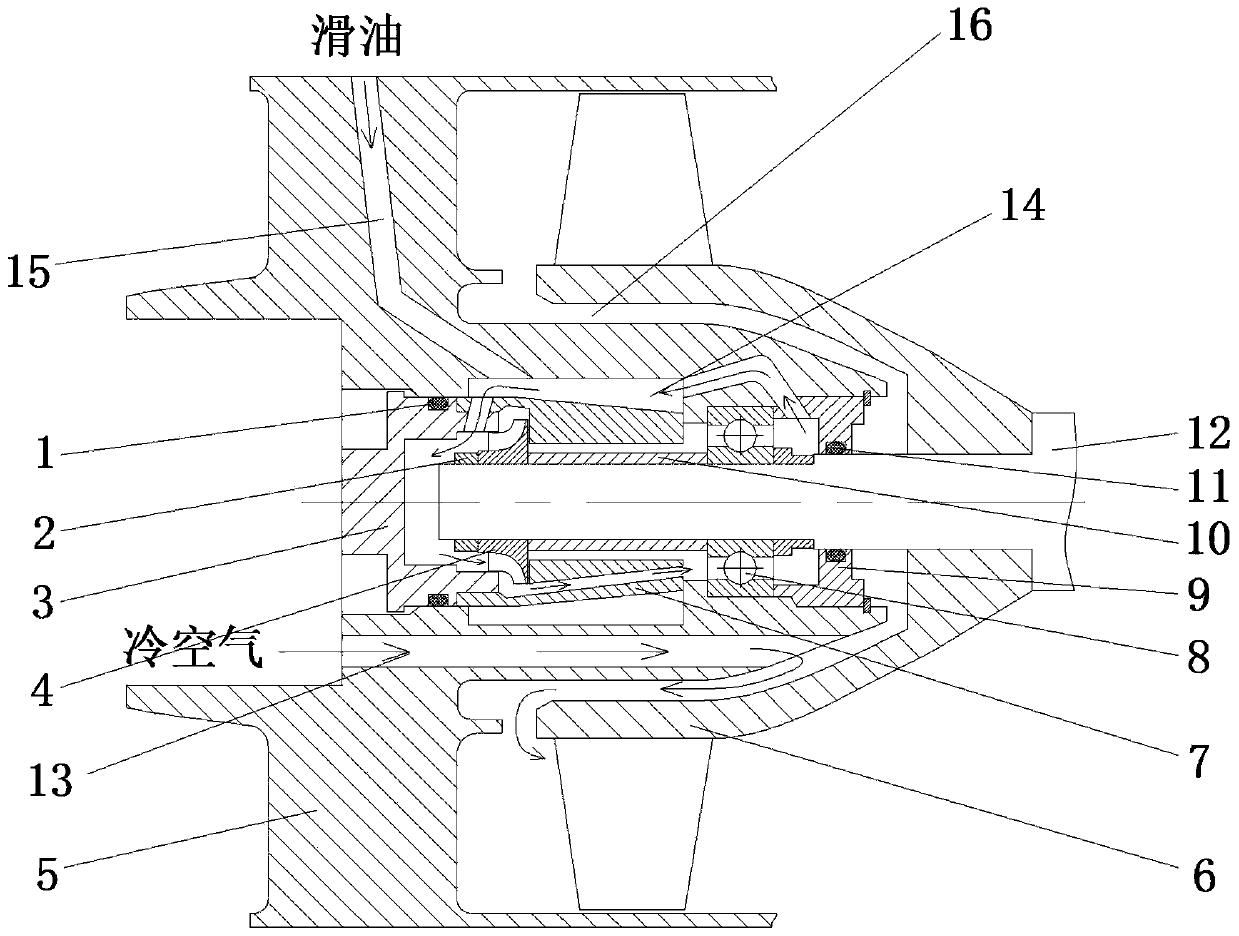

[0030] see Figure 1~2 , a small turbine engine rotor supporting and lubricating integrated structure, including a casing 5, an engine shaft 12 is installed on the casing 5, and a lock nut 2, a closed centrifugal pump 4, and a positioning sleeve 10 are sequentially arranged in series on the engine shaft 12. The bearing 8, the rear blocking cover 9 and the rotor impeller 6, the side of the lock nut 2 away from the rear blocking cover 9 is provided with the front blocking cover 3 connected with the casing 5, and the front blocking cover 3, the casing 5, and the rear blocking cover 9 are sealed and connected, and the casing 5 on the outside of the engine shaft 12 is provided with a strip groove 13. The position where the bearing 8 is installed on the casing 5 and the side wall of the casing 5 are in the form of a cantilever. The front block cover 3 and the rear block cover 9. The closed space formed by the casing 5 is provided with a guide block 7 connecting the closed centrifuga...

Embodiment 2

[0037] This embodiment is further optimized on the basis of implementation 1, specifically:

[0038] The front rubber ring 1 is used for sealing between the front blocking cover 3 and the casing 5, and the rear rubber ring 11 is used for sealing between the rear blocking cover 9 and the casing 5. The design of the front rubber ring 1 makes the connection between the front blocking cover 3 and the casing 5 tighter, avoiding the leakage of the side oil of the front cover, and the design of the rear end cover makes the connection between the dog end cover and the casing 5 tighter. Tight, avoiding the leakage of the side slip oil of the rear end cover.

[0039] As a preferred mode, the engine shaft 12 runs through the casing 5 transversely, one end of the engine shaft 12 is connected with the lock nut 2, the other side of the engine shaft 12 is connected with the rotor impeller 6, and the casing on the side of the rotor impeller 6 is connected. 5 is provided with an annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com