Super pipeline for nuclear power plant as well as manufacturing method thereof

A technology of super pipes and manufacturing methods, which is applied in the direction of detailed information of nuclear power plants, nuclear power plants, nuclear power generation, etc., can solve the problems that cannot meet the use of super pipes, and achieve the goal of increasing the limit of low-cycle fatigue strength, improving the strength of the pipe body, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

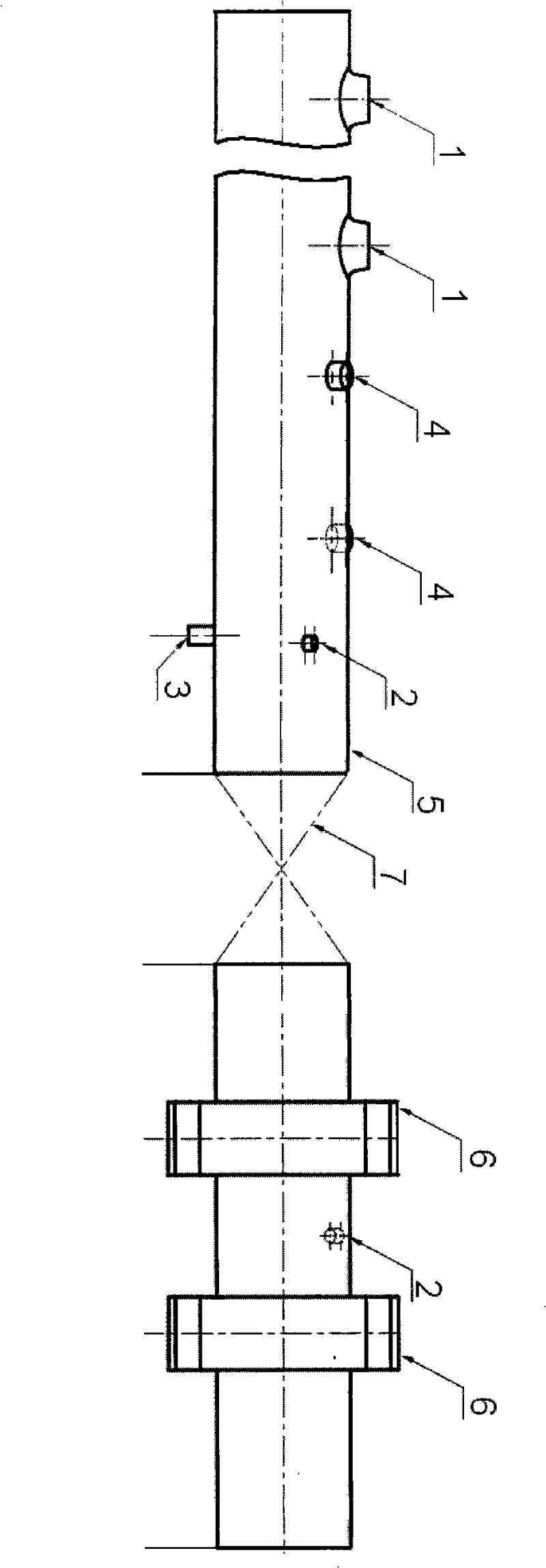

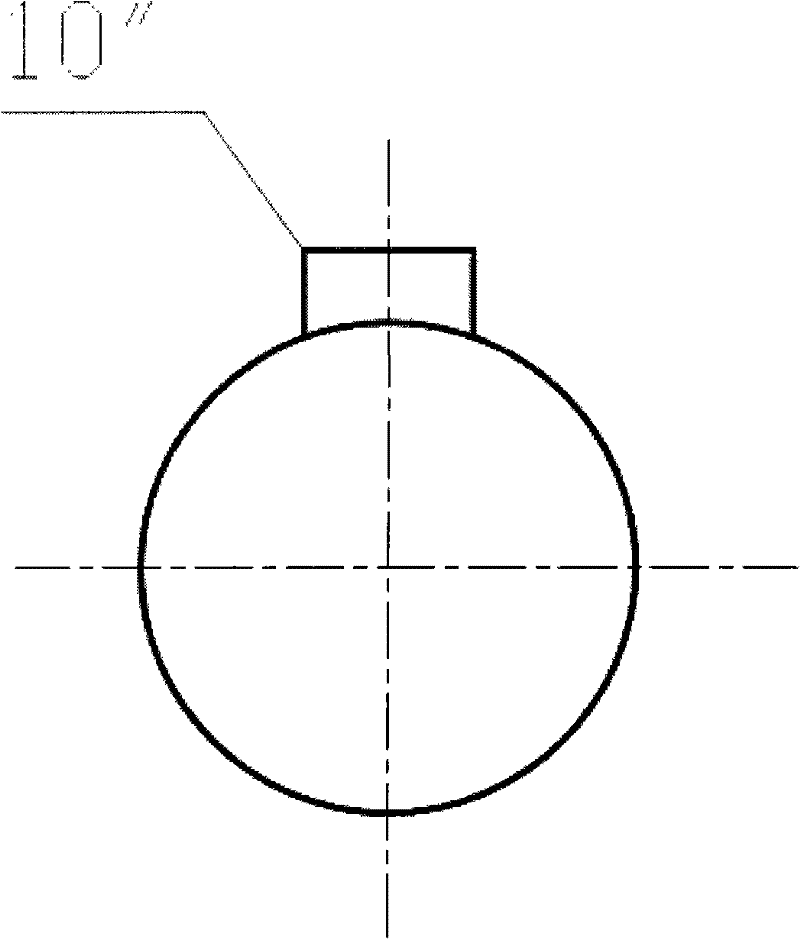

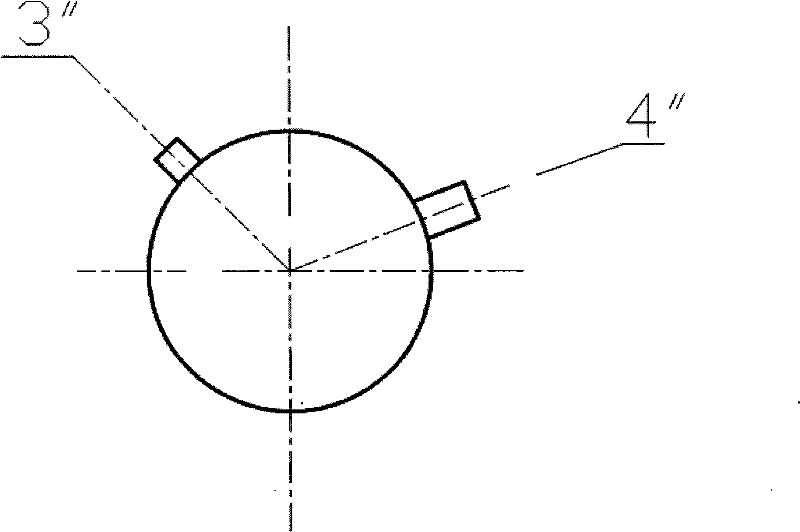

[0037] A kind of super pipe for nuclear power plant of the present invention and the embodiment of manufacturing method thereof are introduced below in conjunction with accompanying drawing:

[0038] Such as Figures 1 to 6 As shown, a super pipeline includes a pipeline 5 and a slam limiter 6; the pipeline is divided into a first section and a second section, the first section is installed upstream of the main steam isolation valve 7, and the second section is installed at the main steam isolation valve Downstream of 7, the nozzles are distributed on the pipeline 5, including 10" nozzle 1, 3" nozzle 2, 4" nozzle 3 and 6" nozzle 4. The nozzle is cylindrical, and its lower end is smoothly transitioned to the pipeline. The size and quantity of the nozzle 2 are determined according to the design requirements. Through extrusion molding, its position is determined according to other pipes connected to the super pipe; the slam limiter 6 is welded together with the second pipe 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com