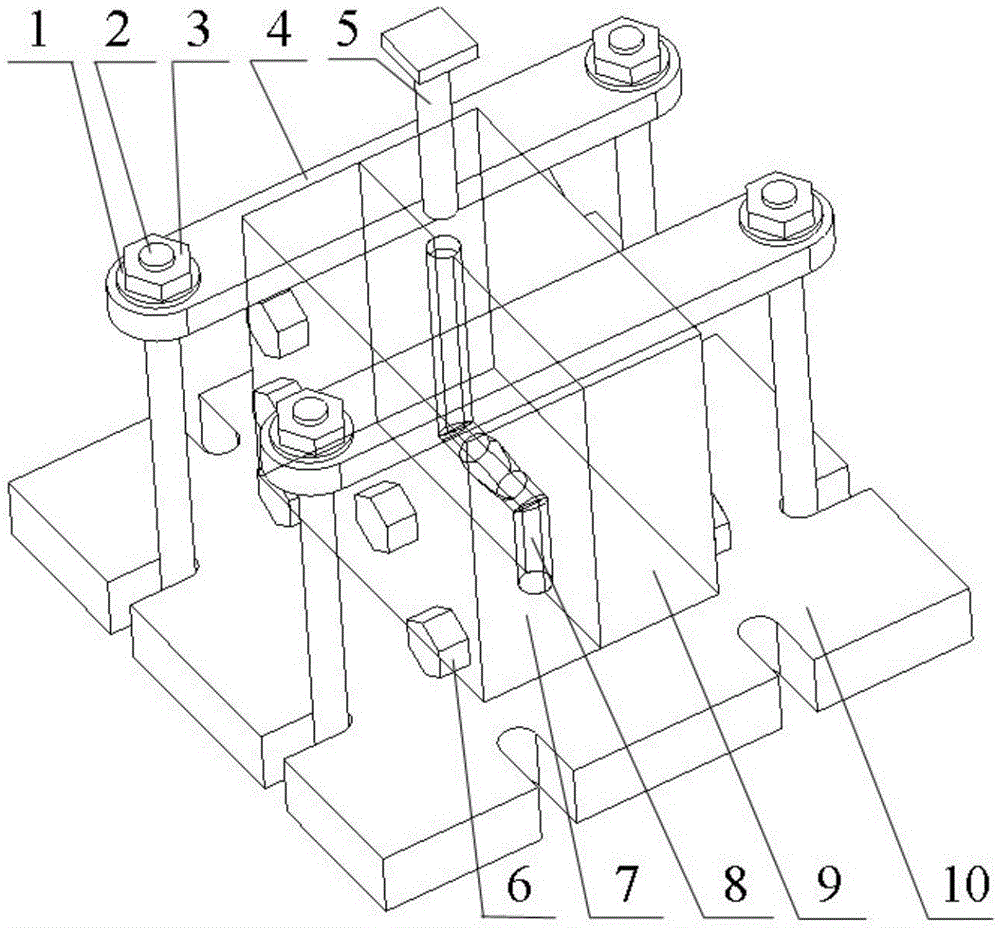

A mold and method for preparing ultrafine crystal bulk material

A block material and ultra-fine grain technology, applied in the direction of metal extrusion dies, etc., can solve problems such as hindering industrial applications, discontinuous processing, and consuming production time, so as to achieve smooth changes, improve forming quality, and prolong die life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

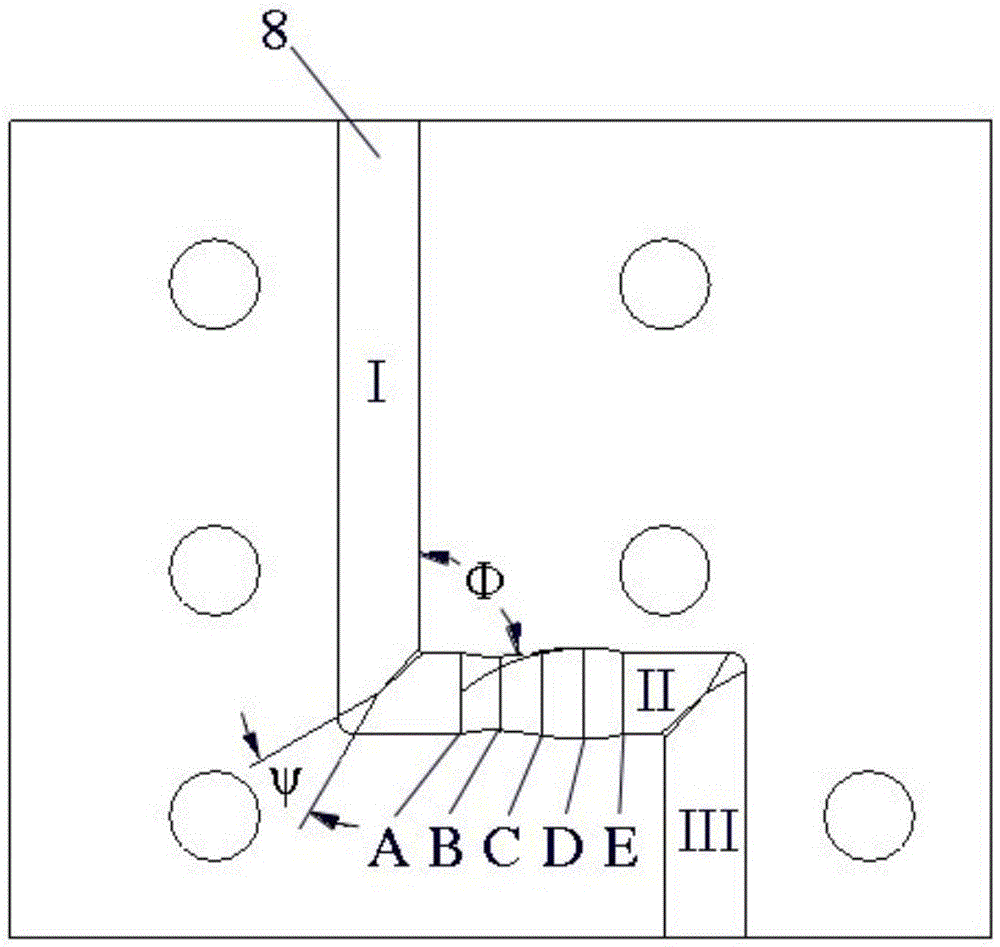

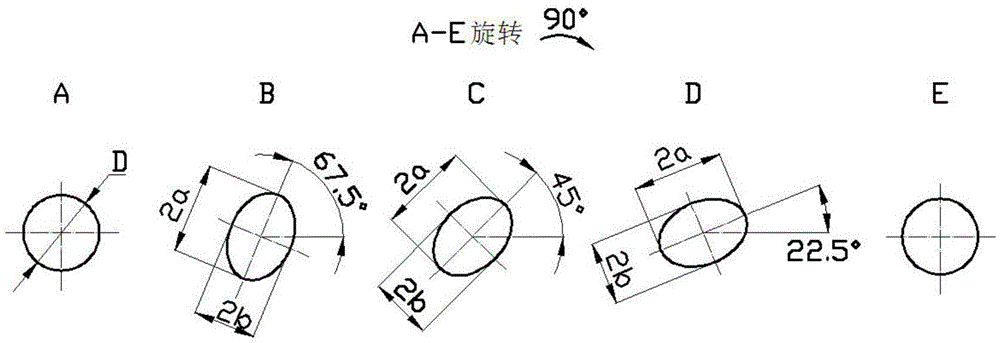

[0031] Apply the mold for preparing ultra-fine crystal block materials proposed by the present invention, determine the inner angle Φ=90° and outer angle Ψ=30° of the extrusion channel (8) of the mold, and use a 30-ton press.

[0032] Step 1, pretreatment: firstly, the extrusion material is selected as the metal block material aluminum alloy 2024 that can be strengthened by heat treatment, and then the metal block material aluminum alloy 2024 is processed into a round bar φ10mm×60mm, and then it is used to improve the round bar Solid solution pretreatment of the plastic forming ability of the material, the specific process conditions can be checked through the aluminum alloy heat treatment manual: keep at 500 ° C for 40 minutes, and then water cool to room temperature;

[0033] Step 2, rotating channel equiradial parallel extrusion: MoS 2 As a lubricant, firstly, the round bar material pretreated in step 1 is deformed in the upper equal radial angle parallel extrusion channel ...

Embodiment 2

[0036] Apply the mold for preparing ultra-fine crystal block materials proposed by the present invention, determine the inner angle Φ=90° and outer angle Ψ=30° of the extrusion channel (8) of the mold, and use a 30-ton press.

[0037] Step 1, pretreatment: first select the extrusion material to be the metal block material aluminum alloy 5052 that cannot be strengthened by heat treatment, and then process the metal block material aluminum alloy 5052 into a round bar φ10mm×60mm, and then proceed to improve the round bar Annealing pretreatment for plastic forming ability; the specific process conditions can be checked through the aluminum alloy heat treatment manual: 300 ° C for 180 minutes to remove the processing stress;

[0038] Step 2, rotating channel equiradial parallel extrusion: MoS 2 As a lubricant, firstly, the round bar material pretreated in step 1 is deformed in the upper equal radial angle parallel extrusion channel (I) section of the extrusion channel (8) for an eq...

Embodiment 3

[0040] Apply the mold for preparing ultra-fine crystal block materials proposed by the present invention, determine the inner angle Φ=90° and outer angle Ψ=30° of the extrusion channel (8) of the mold, and use a 30-ton press.

[0041] Step 1, pretreatment: first select the extrusion material to be stainless steel metal block material 302 that cannot be strengthened by heat treatment, and then process the stainless steel 302 metal block material into a round bar φ10mm×60mm, and then proceed to improve the plastic forming of the round bar The annealing pretreatment of the ability; the specific process conditions can be checked through the aluminum alloy heat treatment manual: 650 ° C for 180 minutes, and the processing stress is removed;

[0042] Step 2, rotating channel equiradial parallel extrusion: MoS 2 As a lubricant, first, the round bar material obtained through the pretreatment of step 1 is deformed in the upper equal radial angle parallel extrusion channel (I) section o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com