Direct orange S dye preparation process

A preparation process and direct technology, applied in the direction of organic dyes, disazo dyes, etc., can solve the problems of restricting the sustainable development of the dye industry, poor product quality consistency, waste of useful substances, etc., to increase production costs and process steps, improve Coupling effect, the effect of solving waste water pollution environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

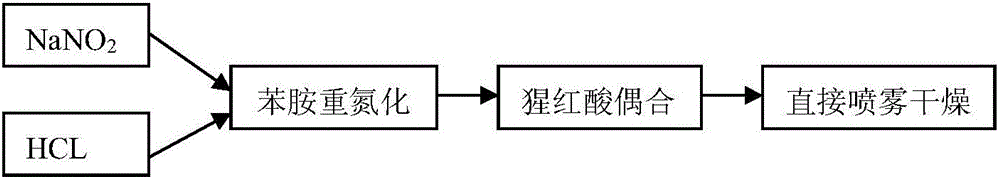

[0027] 1, technological process of the present invention:

[0028]

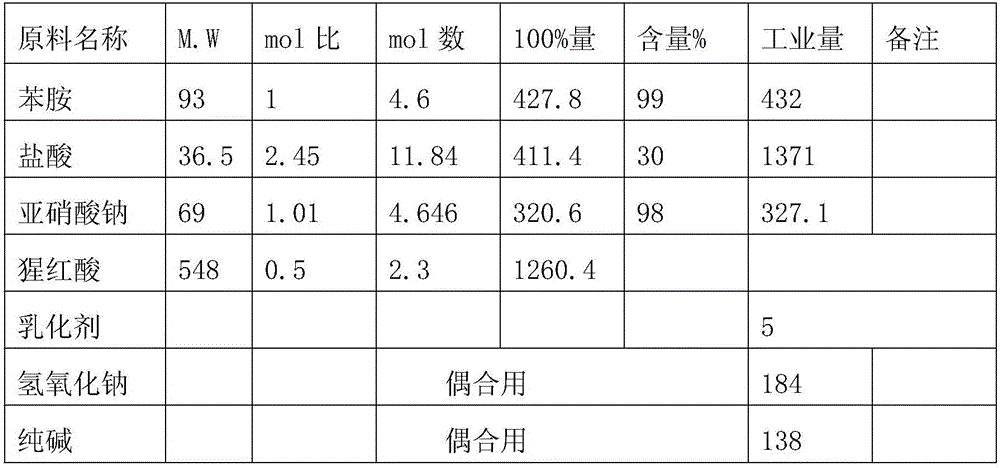

[0029] 2. Ingredients:

[0030]

[0031] 3. The preparation process of direct orange S dye, the steps are as follows:

[0032] (1) Aniline diazotization

[0033] Add 2000L of water to a 15000L diazotization pot, add hydrochloric acid and ice cubes at the same time, add aniline while stirring, control the temperature at t=0-2°C, volume V=7400L, add the pre-dissolved sub Sodium nitrate solution, react for 1 hour, the diazo solution is a transparent liquid, volume v=9200L, to be coupled;

[0034] (2) Scarnic acid coupling

[0035] Add 6000L of water to the coupling tank, add scarlet acid, sodium hydroxide, soda ash and 3-7kg emulsifier TX-10 at the same time, stir an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com