Solar cell module electrode tension test device

A solar cell and testing device technology, which is applied in the field of solar energy, can solve problems such as the inability to test the pulling force of electrodes, and achieve the effects of improving test efficiency, less auxiliary materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

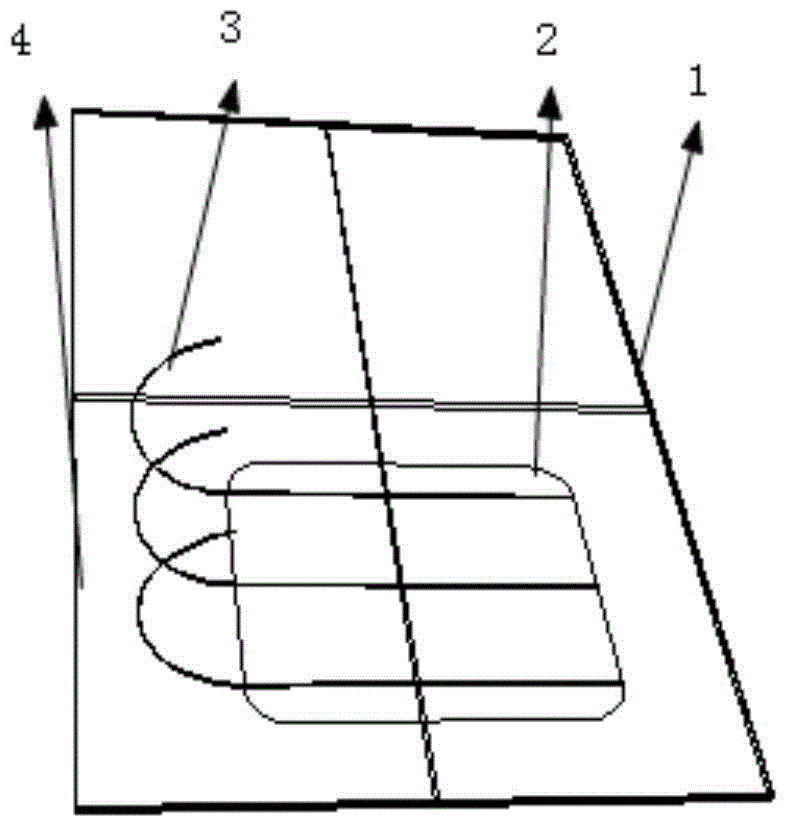

[0024] like figure 1 As shown, a test device for electrode tension in a solar cell assembly, the solar cell assembly includes a silicon cell 2, a welding ribbon 3 welded on the silicon cell, and the test device includes a device for installing and fixing the silicon cell Glass 1, and a tensile machine. One end of the tensile machine is connected to the glass 1, and the other end clamps the welding head of the ribbon 3. The tensile machine is started to test the separation force of the ribbon and the silicon cell.

[0025] The tension machine includes a separation end, a transmission device, a tension sensor, a main body of the tension machine, and a computer.

[0026] The separated end is composed of two opposite clamps, one of which is connected with the transmission device and the tension sensor and can move freely. The sensor is connected with the computer, and the tension value can be directly read through the computer. Among them, the clamp of the tensile machine is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com