Sealing performance detection method for single-frame protection air-tight door

A detection method and airtight door technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems of hidden dangers in engineering protection performance and the inability to implement airtight performance testing, and achieve savings Operators and auxiliary materials, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

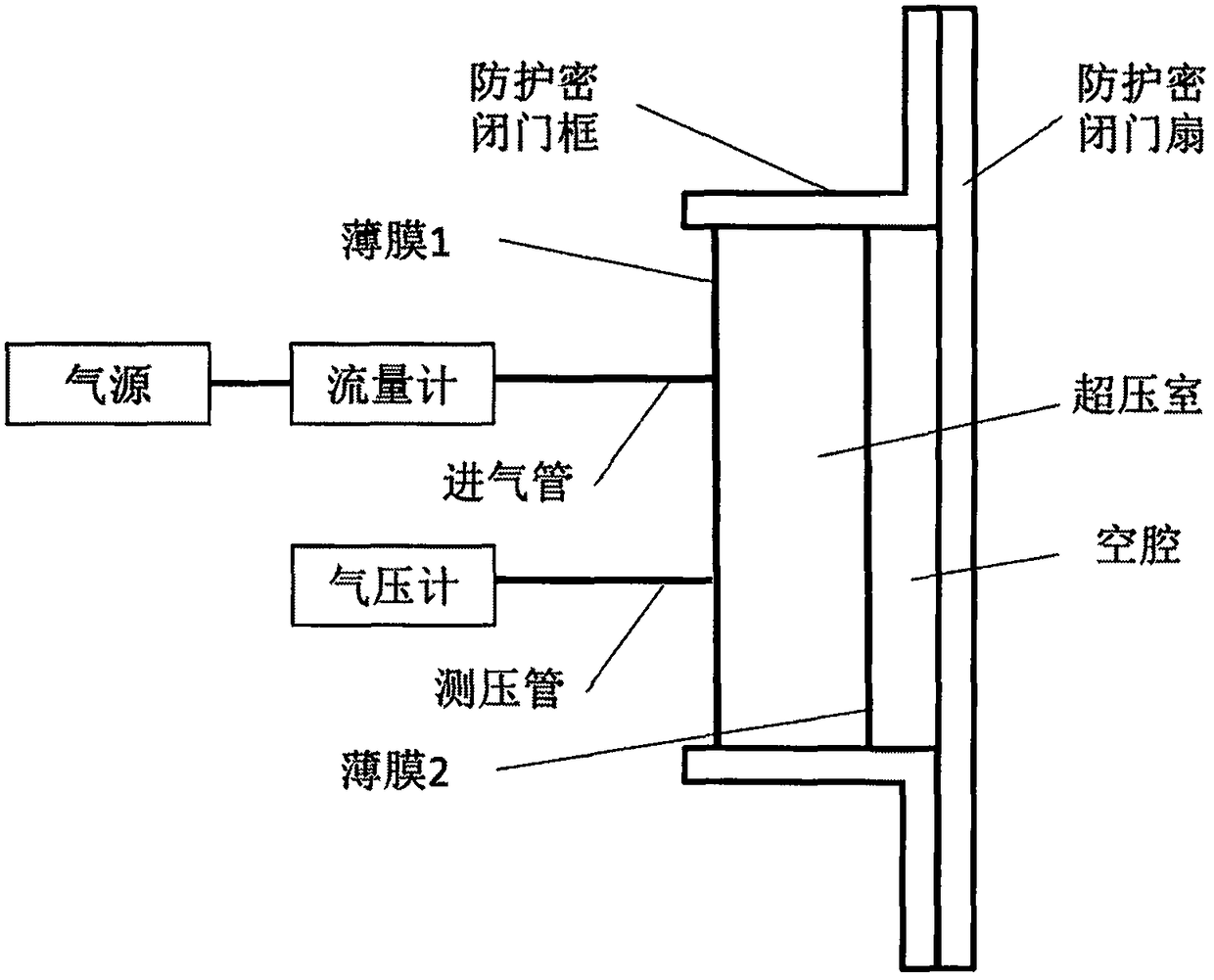

[0014] like figure 1 As shown, a method for testing the airtight performance of a single protective airtight door is to use film 1 and film 2 to seal both sides of the protective airtight door frame to form an overpressure chamber, and confirm that the air leakage in the overpressure chamber is less than 0.001m 3 After / h, the airtight performance test can be carried out.

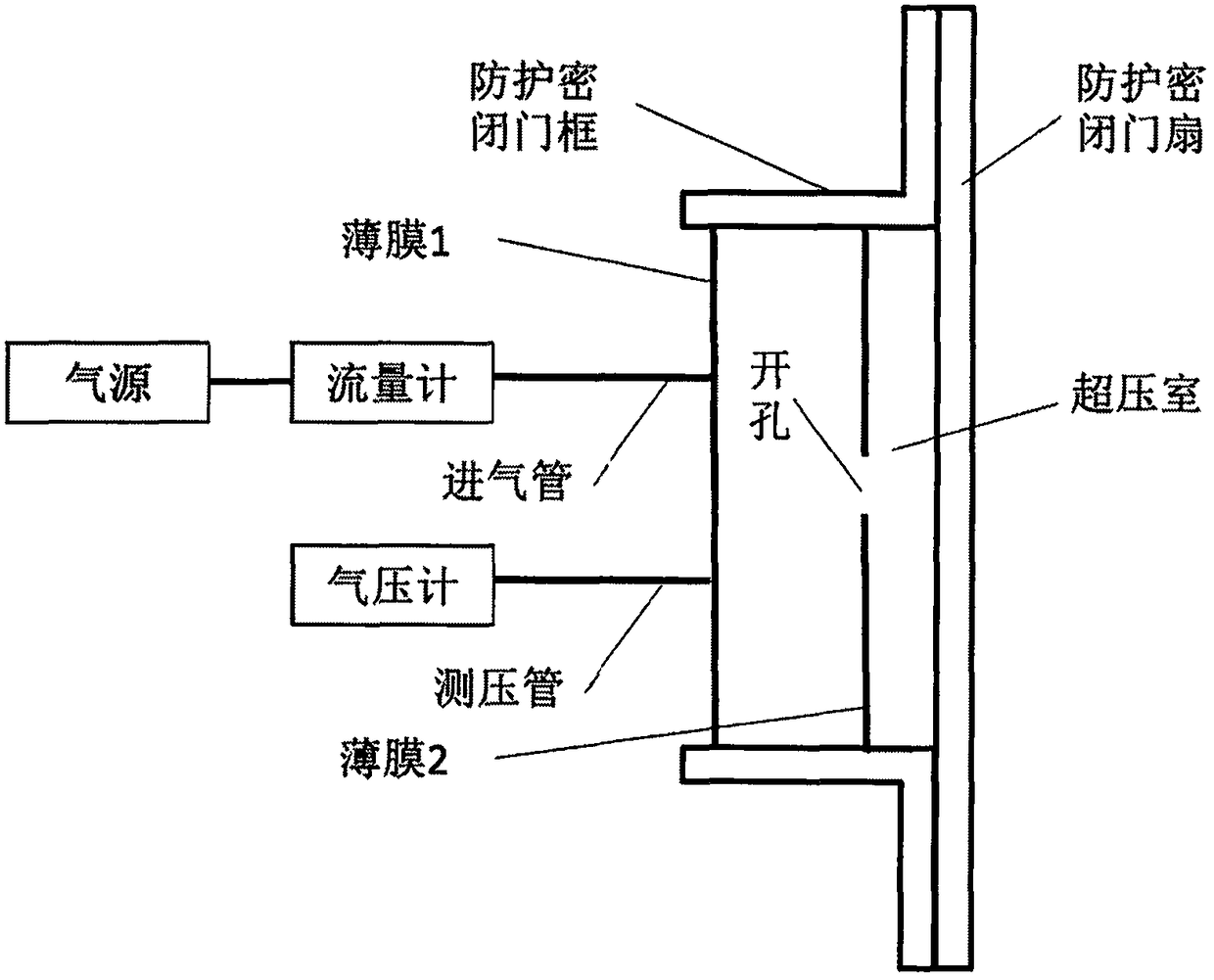

[0015] like figure 2 After the reserved opening on the film 2 is opened as shown, the sealing performance of the protective airtight door is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com