Lifting method for large-scale tower equipment

A hoisting method and equipment technology, which is applied in the hoisting field of large-scale tower equipment, can solve the problems of complicated fabrication of reinforced frames, complicated hoisting process, and difficult installation, so as to save prefabrication time and cost, simple hoisting point type, and easy hoisting The effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

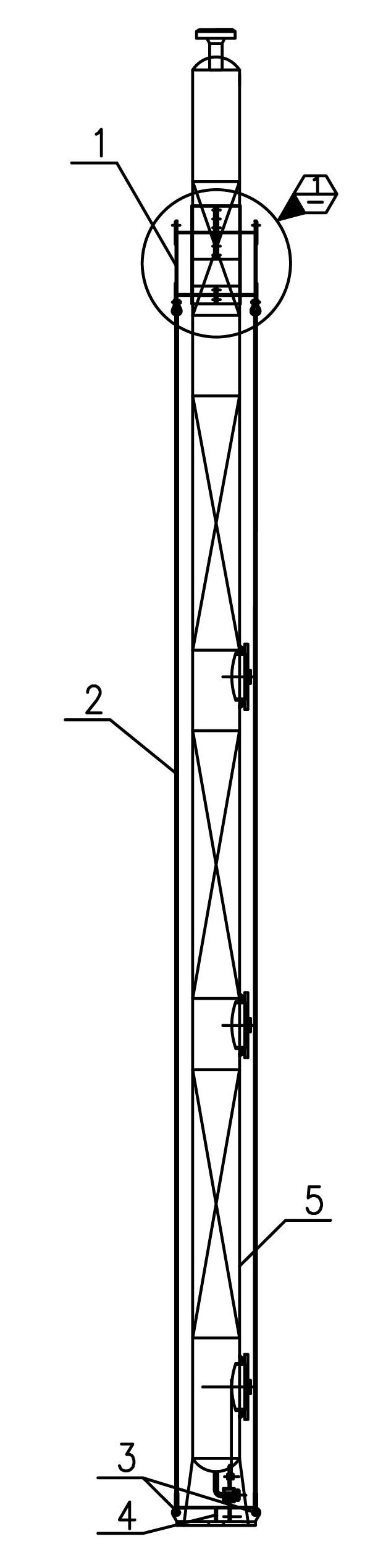

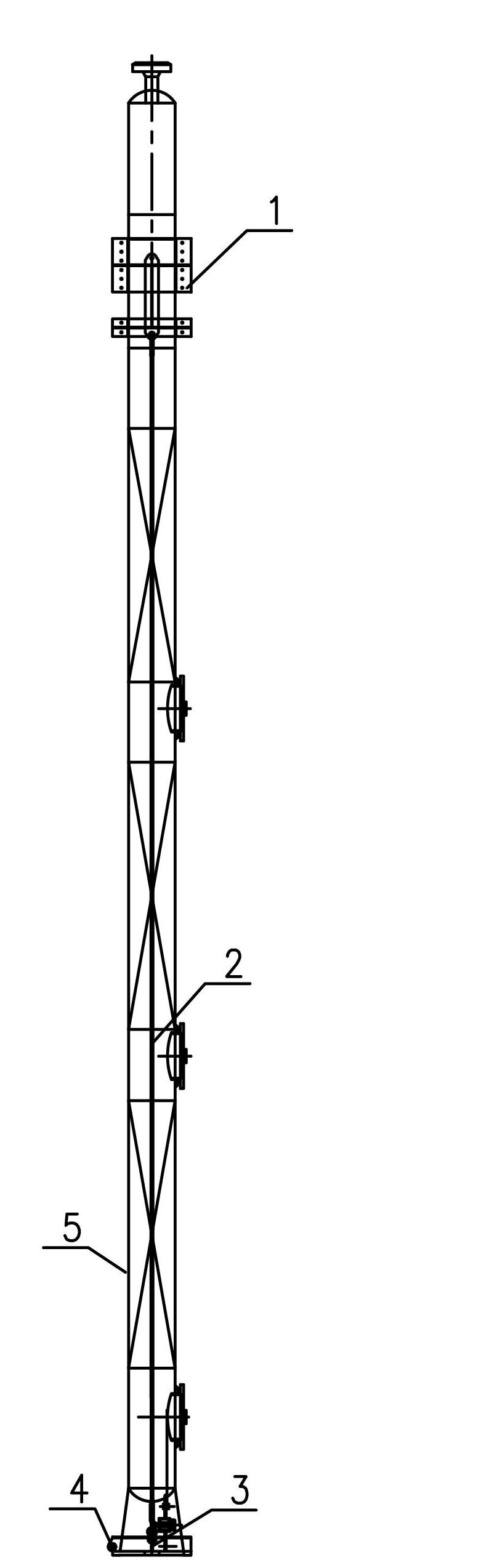

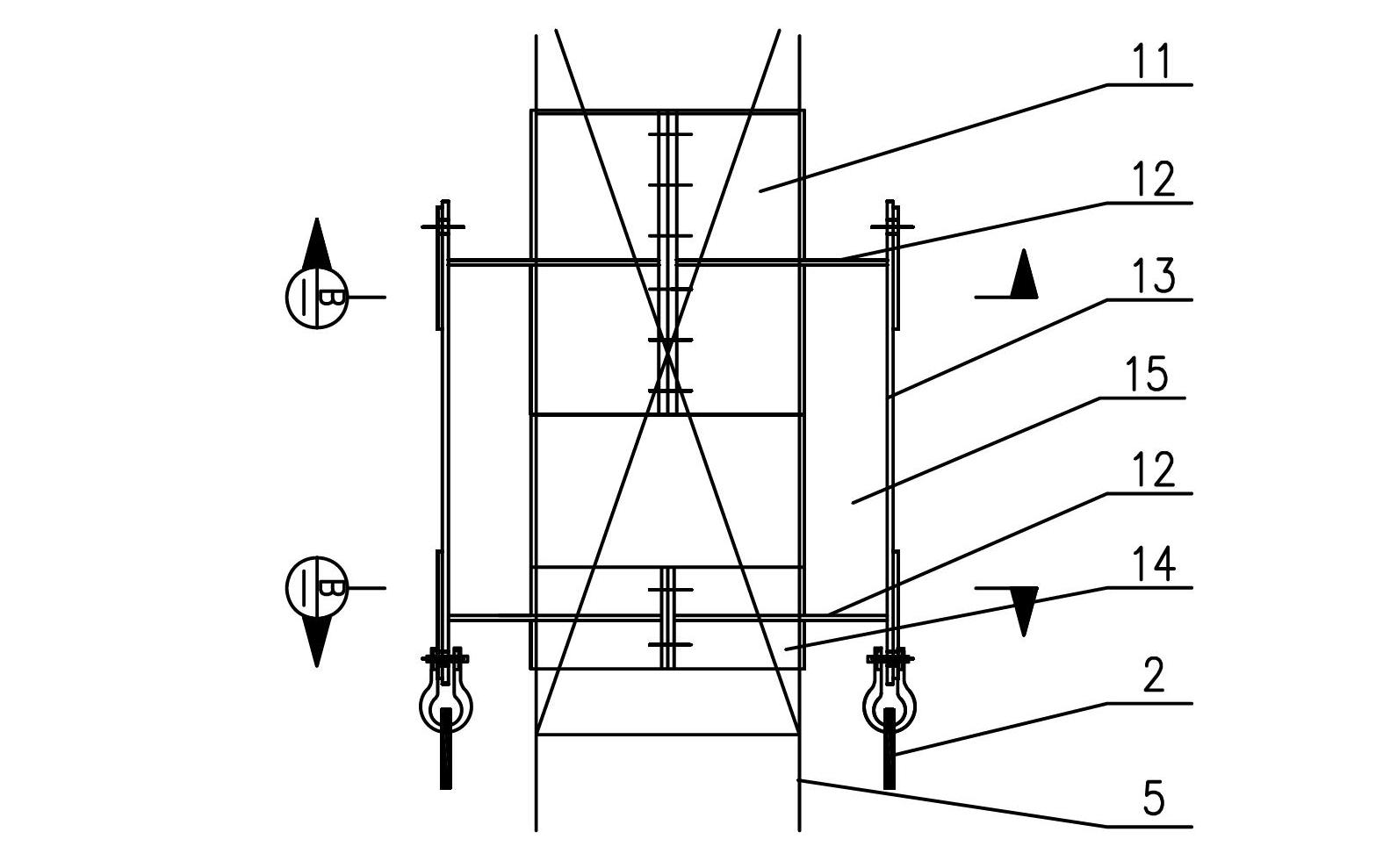

[0023] see Figure 1 to Figure 7 , a hoisting method for large-scale tower equipment, comprising the following steps:

[0024] 1) Weld two connecting lugs 3 and one bottom lifting lug 4 on the equipment base, the two connecting lugs 3 are located on both sides of the equipment base, and the bottom lifting lug 4 is located on the two connecting lugs Between the plates 3; the hoop hoisting structure 1 is fixed on the top of the equipment, the hoop hoisting structure 1 includes the hoop fastened on the equipment tower 5, and the hoop is connected to the two top hoisting lugs 13 through the ring plate 12 , the two top lifting lugs 13 are located on both sides of the equipment tower 5, parallel to the center line of the equipment tower 5, and opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com