Preparation method of tantalum and niobium composite carbide

A composite carbide, tantalum and niobium technology, applied in the fields of tantalum compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high difficulty in carbonization, poor mixing of uniformity and chemical activity, multiple energy sources and raw materials, etc., and achieve reduction of doping Opportunity of miscellaneous, narrow particle size distribution, good chemical activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

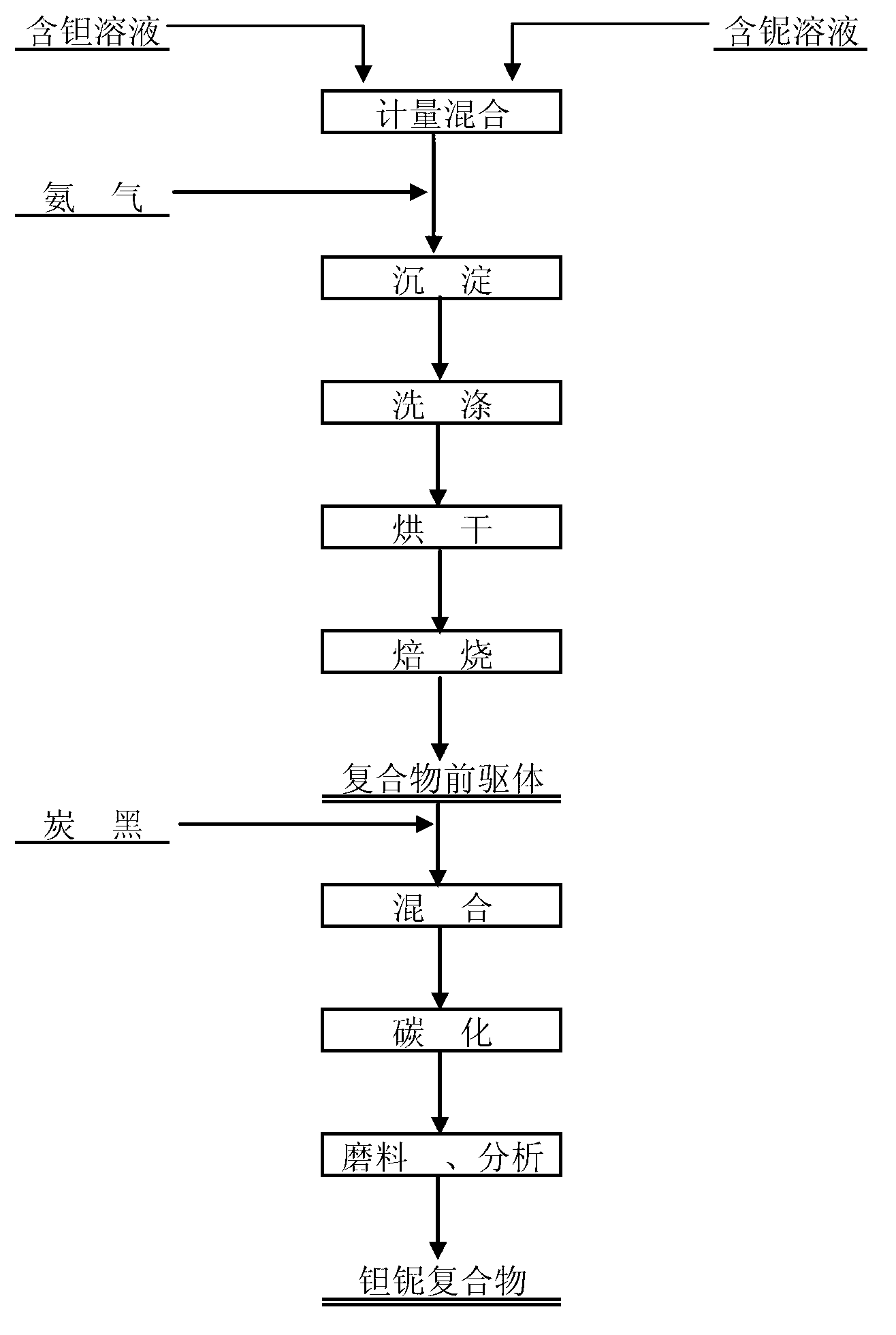

[0019] The preparation method of tantalum-niobium composite carbide of the present invention, technological process is: select HF-H 2 SO 4 The tantalum-containing solution and the niobium-containing solution produced by the system extraction process are mixed together according to the accurate calculation of the tantalum-niobium composite carbide tantalum-niobium ratio produced according to the needs, and then the precipitant A is added for chemical co-precipitation reaction to obtain a mixed tantalum-niobium hydroxide Slurry, the slurry is washed with ammonia water or pure water, and after drying, a mixed powder of tantalum hydroxide and niobium hydroxide is obtained. The powder is roasted at 800°C-1200°C to obtain a tantalum-niobium composite carbide precursor, and carbon black is added. After carbonization, ball milling and sieving, the final product tantalum-niobium composite carbide is obtained.

[0020] 1. The tantalum-containing solution and the niobium-containing solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com