Preparation method for P-type CuAlO2 semiconductor material

A bulk material and semiconductor technology, applied in the field of preparation of CuAlO2 inorganic semiconductor bulk material, can solve problems such as adverse effects of materials, and achieve the effects of low pressure, simple process, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

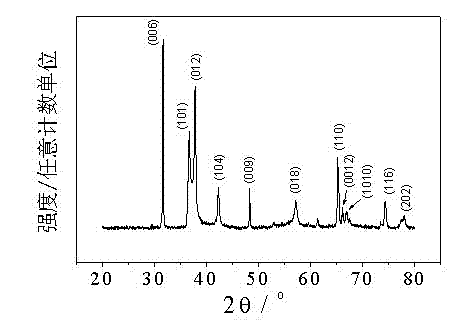

Examples

Embodiment 1

[0034] (1) Cu with a purity of 99.99% 2 O powder and Al with a purity of 99.999% 2 o 3 The powder is dosed at a molar ratio of 1:1, and then put into a ball mill jar for full grinding to obtain a uniformly mixed powder with a particle size not exceeding 300 nm.

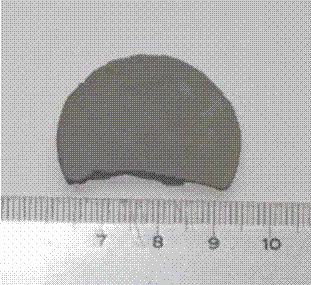

[0035] (2) Using a powder tablet press, hold the pressure for 3 minutes under a static compression pressure of 30 MPa, and press the uniformly mixed powder into a cylindrical target blank with a diameter of about 3 cm and a height of 2 mm.

[0036] (3) Place the pressed target blank in the alumina ceramic boat, and then push the ceramic boat into the center of the alumina ceramic tube furnace. One end of the ceramic tube is connected to the argon gas cylinder through a set of sealing flanges and a vacuum pipeline with an inflation valve; the other end of the ceramic tube is connected to a vacuum pump through another set of sealing flanges and a vacuum pipeline with an air release valve .

[0037] (4) Turn on the v...

Embodiment 2

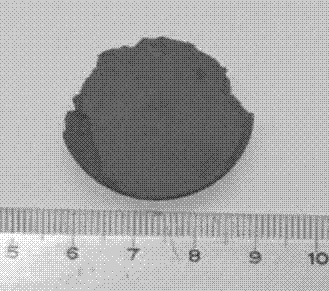

[0047] (1) Cu with a purity of 99.99% 2 O powder and Al with a purity of 99.999% 2 o 3 The powder is dosed at a molar ratio of 1:1, and then put into a ball mill jar for full grinding to obtain a uniformly mixed powder with a particle size not exceeding 300 nm.

[0048] (2) Using a powder tablet press, hold the pressure for 2 minutes under a static compression pressure of 30 MPa, and press the uniformly mixed powder into a cylindrical billet with a diameter of about 3 cm and a height of 4 mm.

[0049] (3) Place the pressed target blank in the alumina ceramic boat, and then push the ceramic boat into the center of the alumina ceramic tube furnace. One end of the ceramic tube is connected to the argon gas cylinder through a set of sealing flanges and a vacuum pipeline with an inflation valve; the other end of the ceramic tube is connected to a vacuum pump through another set of sealing flanges and a vacuum pipeline with an air release valve .

[0050] (4) Turn on the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com