A method for preparing β-tricalcium phosphate based on multidimensional swinging nanometer ball milling

A multi-dimensional swing, tricalcium phosphate technology, applied in chemical instruments and methods, phosphorus compounds, medical science, etc., can solve problems such as large particle size of raw materials, existence of β-tricalcium phosphate impurity phase, imbalance of calcium-phosphorus atomic ratio, etc. Achieve sufficient solid phase reaction, facilitate mass production, and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

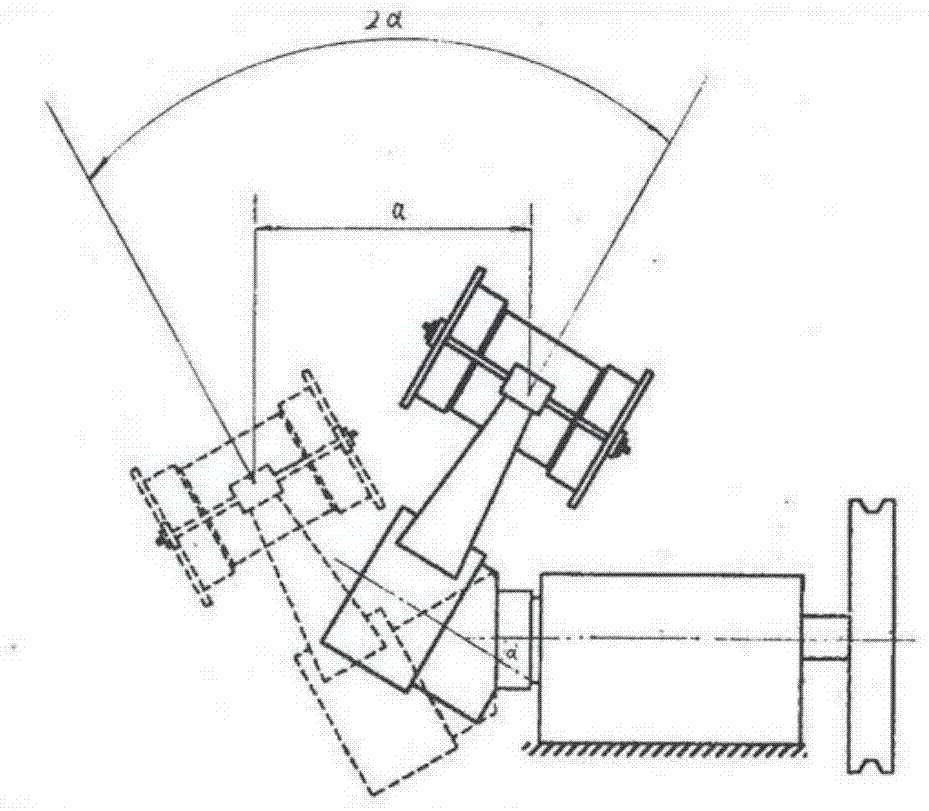

Method used

Image

Examples

Embodiment 1

[0027] Dicalcium phosphate and calcium carbonate were ball-milled for 6 hours at a speed of 300r / min using a multi-dimensional swinging nano ball mill, and then the calcium hydrogen phosphate (CaHPO 4 2H 2 O) 37.86g and calcium carbonate (CaCO 3 ) 11.81g, and then add 70mL of absolute ethanol; the above-mentioned mixed solution was stirred electrically for 3h under ultrasonic to make it fully mixed and dispersed evenly to obtain a slurry; the slurry was dried in an oven, and then placed in a muffle furnace at Calcining at 900° C. for 3 hours to obtain a powder; finally, dispersing the calcined powder in deionized water and drying by suction filtration to obtain a β-tricalcium phosphate powder.

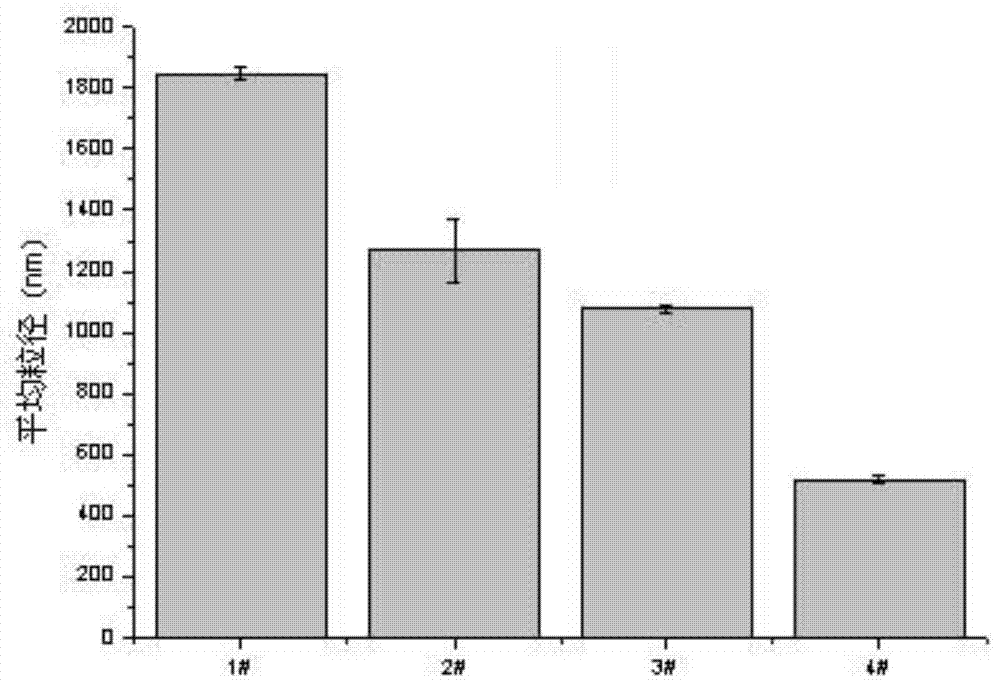

[0028] In this embodiment, the average particle diameter of calcium hydrogen phosphate and calcium carbonate after ball milling by a multidimensional swinging nano ball mill is compared with the average particle diameter after ball milling by an ordinary planetary ball mill, and the r...

Embodiment 2

[0030] Using a multi-dimensional swinging nano ball mill with a speed of 500r / min, calcium pyrophosphate and calcium carbonate were ball milled for 12 hours respectively, and then the calcium pyrophosphate (Ca 2 P 2 o 7 )45.91g and calcium carbonate (CaCO 3 ) 18.09g, and then add 100mL of deionized water; the above mixed solution was stirred electrically for 4h under ultrasonic to make it fully mixed and dispersed evenly to obtain a slurry; the slurry was dried in an oven, and then placed in a muffle furnace at Calcining at 1000° C. for 2 hours to obtain a powder; finally, dispersing the calcined powder in deionized water and drying by suction filtration to obtain a β-tricalcium phosphate powder.

Embodiment 3

[0032] Calcium pyrophosphate and calcium hydroxide were respectively ball-milled for 9 hours at a speed of 400r / min by a multi-dimensional swinging nano ball mill, and then the calcium pyrophosphate (Ca 2 P 2 o 7 )45.91g and calcium hydroxide (Ca(OH) 2 ) 13.39g, and then add 90mL of absolute ethanol; the above-mentioned mixed solution was stirred electrically for 4h under ultrasonic to make it fully mixed and dispersed evenly to obtain a slurry; the slurry was dried in an oven, and then placed in a muffle furnace at Calcining at 850° C. for 3 hours to obtain a powder; finally, dispersing the calcined powder in deionized water and drying by suction filtration to obtain a β-tricalcium phosphate powder.

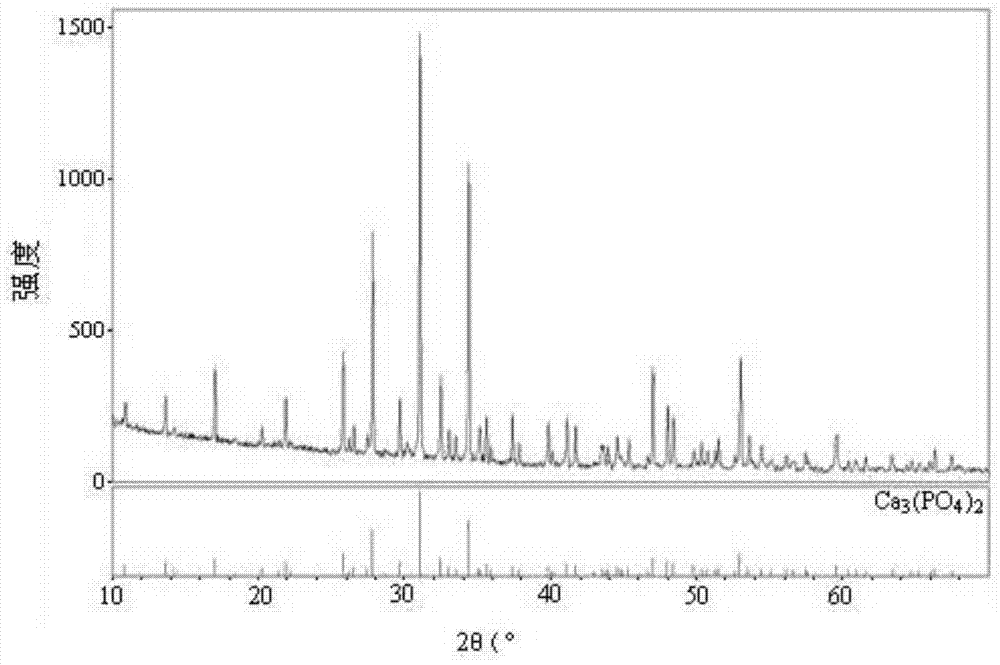

[0033] The XRD spectrogram of embodiment 1~3 gained β-tricalcium phosphate powder and the contrast figure of standard spectrogram are as follows image 3 Shown; its IR spectrum is shown in Figure 4 shown. Depend on image 3 and Figure 4 It can be seen that the β-tricalc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com