Carbonization-activation integral furnace for producing active carbon

A technology for the production of activated carbon and carbonization, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of low production cost, thermal corrosion of flue gas, waste of heat sources, etc., and achieve effective pollution prevention, environmental purification, and The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

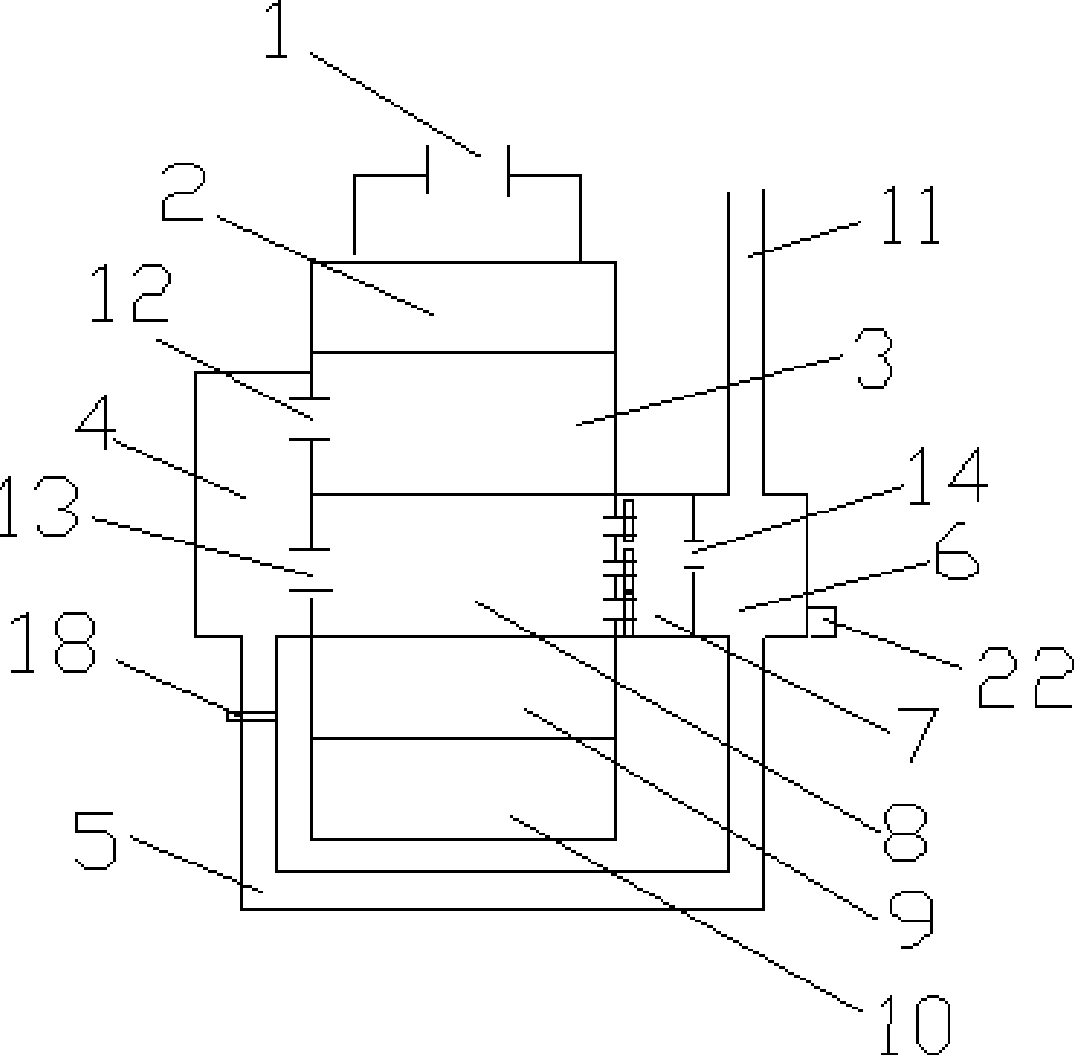

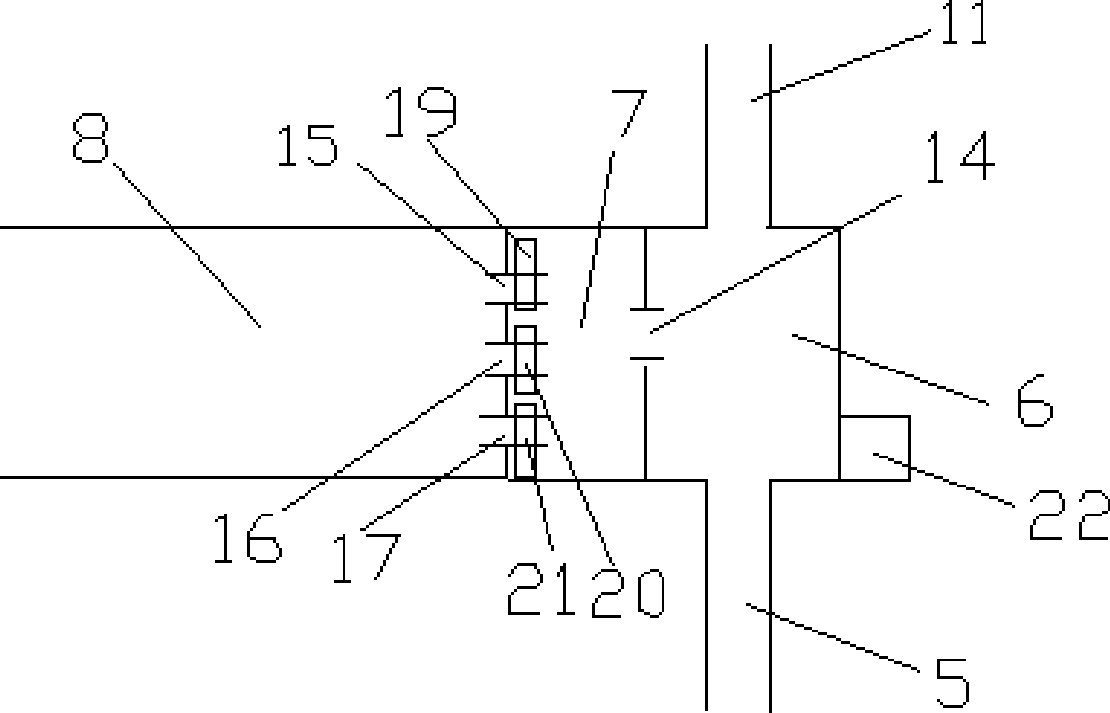

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] Such as figure 1 As shown, the integrated carbonization and activation furnace of the present invention consists of a feed port 1, a preheating chamber 2, a carbonization chamber 3, a heat storage chamber 4, an exhaust pipe 5, a preheating boiler 6, a cylinder 7, an activation chamber 8, and a cooling chamber 9 , The feeder 10 and the outlet pipe 11 are composed. The furnace body is rectangular, and its size can be adjusted according to the production requirements. In the specific implementation, the size of the equipment is 7.5 meters high, 4.5 meters wide, and 4.5 meters long. The main building materials are machine-made bricks, refractory soil, refractory bricks, Refractory cement, metal frame and first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com