Construction method for bank protection engineering construction through integral steel sliding formwork structure

A technology for revetment engineering and construction method, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of cumbersome operation process, consuming manpower and material resources, occupying auxiliary materials, etc., and achieves simple operation process, less auxiliary materials and smoothness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

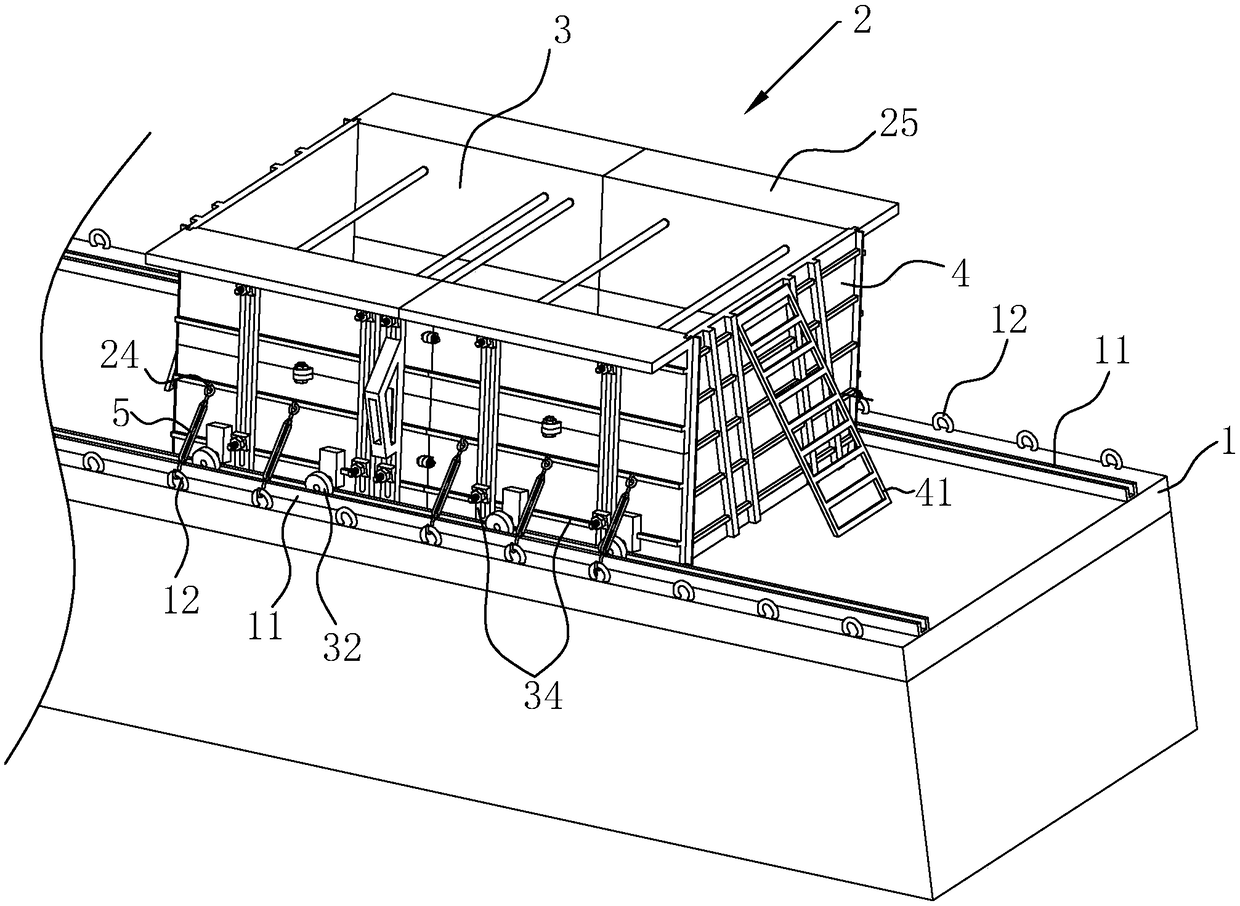

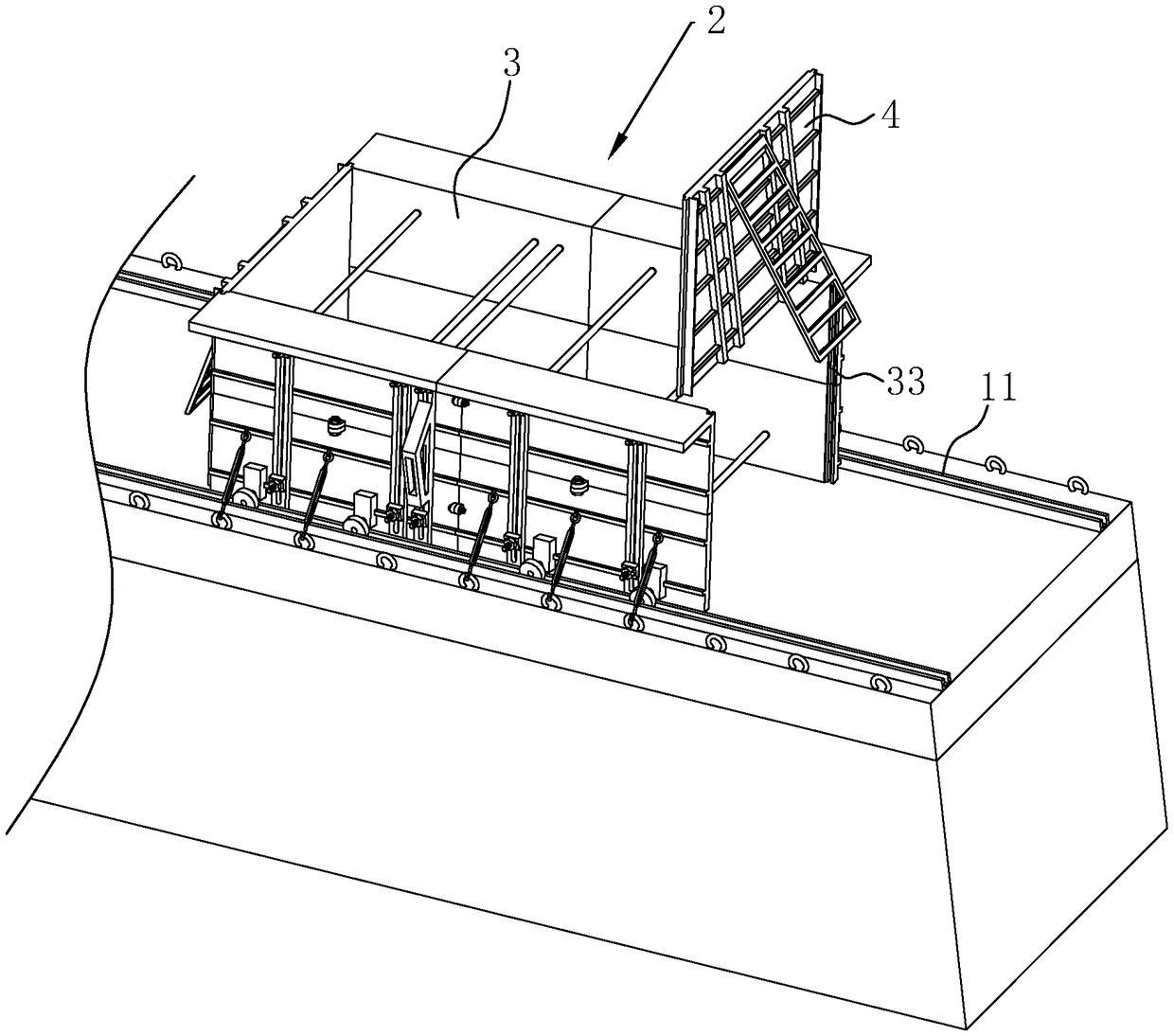

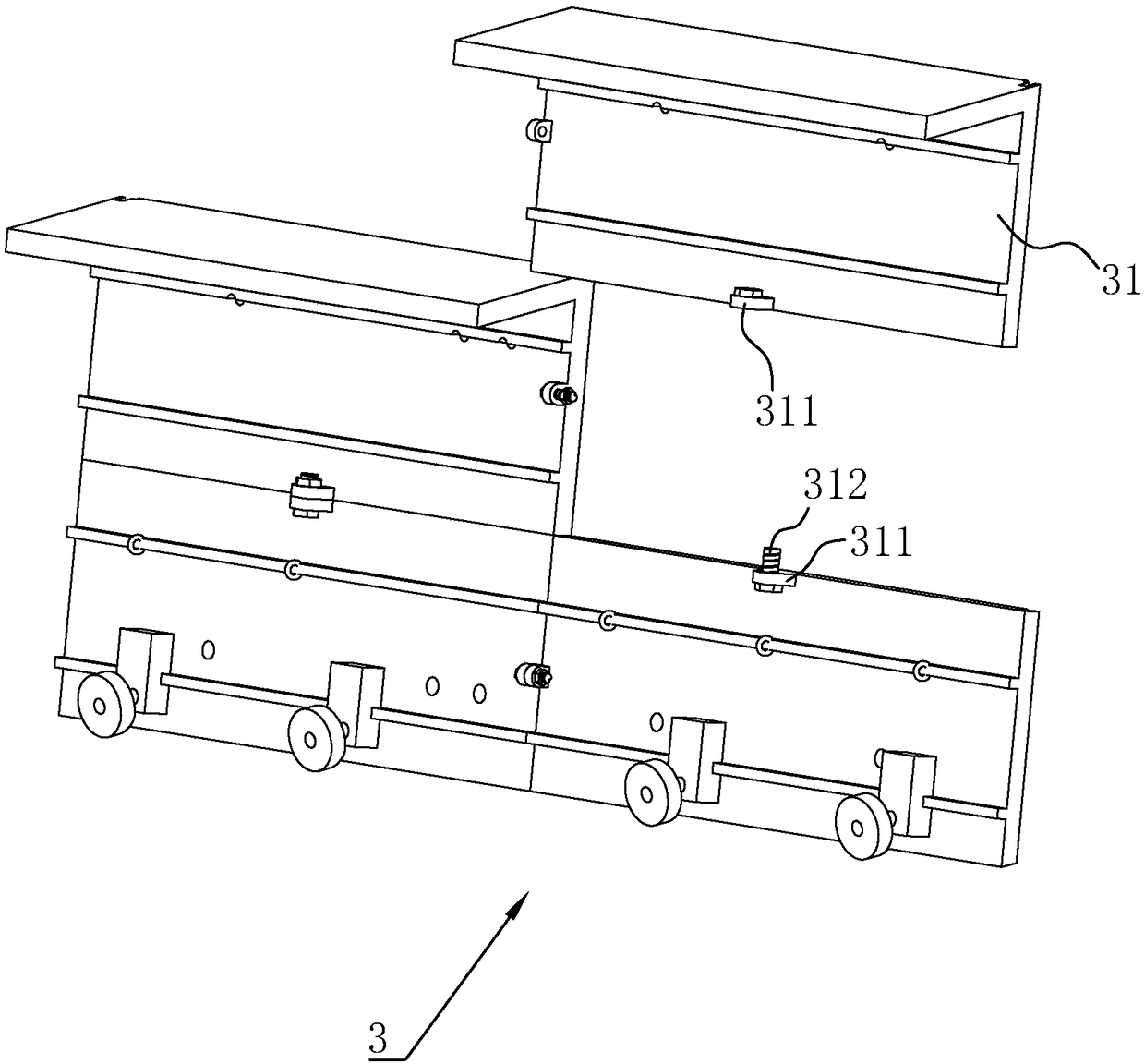

[0040] A kind of construction method of bank revetment construction adopts integral steel sliding form structure, and its construction method comprises the following steps:

[0041] S1. Plan the position of the retaining wall according to the conditions of the river bank, and measure the setting out, such as figure 1 As shown, the foundation cushion 1 is laid according to the setting-out line, and the foundation cushion 1 includes a gravel cushion laid on the embankment and C20 concrete poured on the gravel cushion. The cushion layer is the middle layer between the concrete foundation and the foundation soil. During the construction of the retaining wall, the foundation cushion layer 1 isolates the soil, prevents groundwater from seeping up, and smooths the surface layer to facilitate the construction of the retaining wall. In addition, circular rings 12 are buried in arrays on both sides of the foundation cushion layer 1 along its length direction.

[0042] S2, such as figu...

Embodiment 2

[0054] A kind of construction method of bank revetment construction adopts integral steel sliding form structure, and its construction method comprises the following steps:

[0055] S1. Plan the position of the retaining wall according to the conditions of the river bank, and measure the setting out, such as figure 1 As shown, the foundation cushion 1 is laid according to the setting-out line, and the foundation cushion 1 includes a gravel cushion laid on the embankment and C20 concrete poured on the gravel cushion. The cushion layer is the middle layer between the concrete foundation and the foundation soil. During the construction of the retaining wall, the foundation cushion layer 1 isolates the soil, prevents groundwater from seeping up, and smooths the surface layer to facilitate the construction of the retaining wall. In addition, circular rings 12 are buried in arrays on both sides of the foundation cushion layer 1 along its length direction.

[0056] S2, such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com