Protection method of prestressed concrete post-tensioning steel strand anchorage

A steel strand and concrete technology, applied in the field of science, can solve problems such as the difficulty of fully sealing the anchor clips and anchor holes, the complex structure of the porous anchorage system, and the impact on the bonding of new and old concrete, so as to ensure long-term service safety , The protective operation specification is easy to follow, and the protective effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A prestressed concrete post-tensioned steel strand 10 anchorage protection method, the protection method requirements of the prestressed concrete post-tensioned steel strand 10 anchorage are as follows:

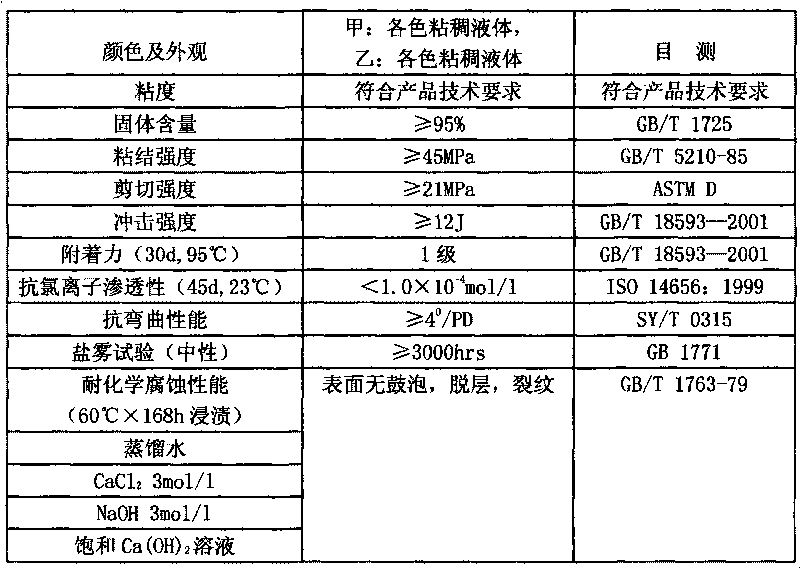

[0061] 1) First, use a solvent-free thermosetting polymer liquid paint to repair and pour the paint to specifically perform surface coating anti-corrosion maintenance treatment, and form an insoluble and fused durable protective coating on the outside of the anchorage of the steel strand 10; the solvent-free thermosetting polymer liquid The performance index of the coating should meet the requirements stated in Table 1;

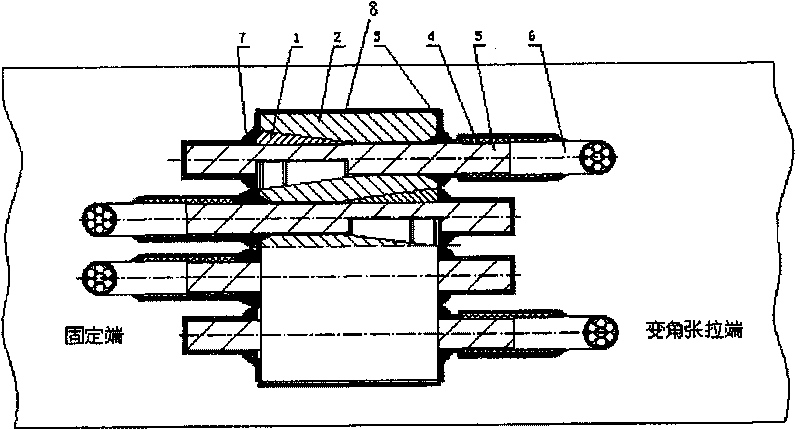

[0062] 2) Select reasonable perfusion plastic jackets and fixtures: through reasonable design, chlorine-free plastic jackets can protect the prestressed concrete post-tensioned steel strand 10 anchors on site, whether they have been stretched or not. The tension can be installed quickly, and the seal is reliable, and the length of the injection is arb...

Embodiment 2

[0087] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

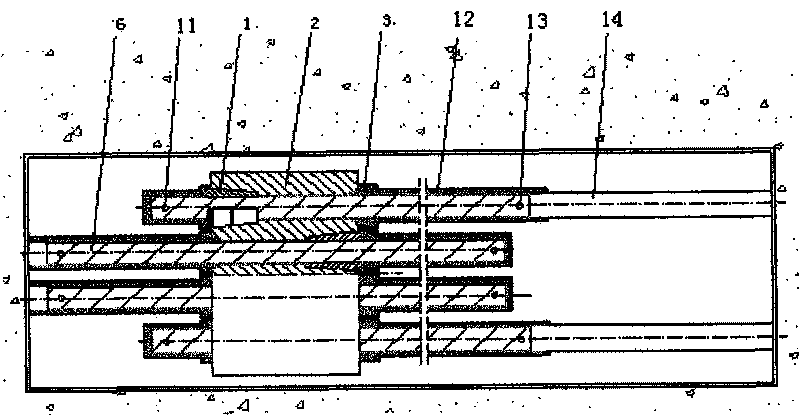

[0088] In the prestressed concrete post-tensioned steel strand 10 anchorage protection method described in this embodiment, the anti-corrosion construction scheme of the anchor head of the pre-stressed concrete post-tensioned steel strand 10 anchor is specifically the sheath pipe anti-corrosion method: The specific requirements of the sheath pipe anti-corrosion method are (anchor system anti-corrosion as attached figure 2 ):

[0089] 1) After the on-site prestressed steel strand 10 is stretched, use a special hydraulic cutting tool to cut off the excess steel strand 10 at the tensioned end;

[0090] 2) Use an appropriate method to quickly remove the oil stains left during the anchorage tensioning process, and then use a special cleaning agent to quickly clean up the remaining pollutants;

[0091] 3) According to the stripping length of the 10 steel stran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com