Cantilever type semi-automatic inner separating plate welding device and method

A welding device and semi-automatic technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as difficult positioning, and achieve the effects of good working environment, lower production costs, and fewer personnel operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

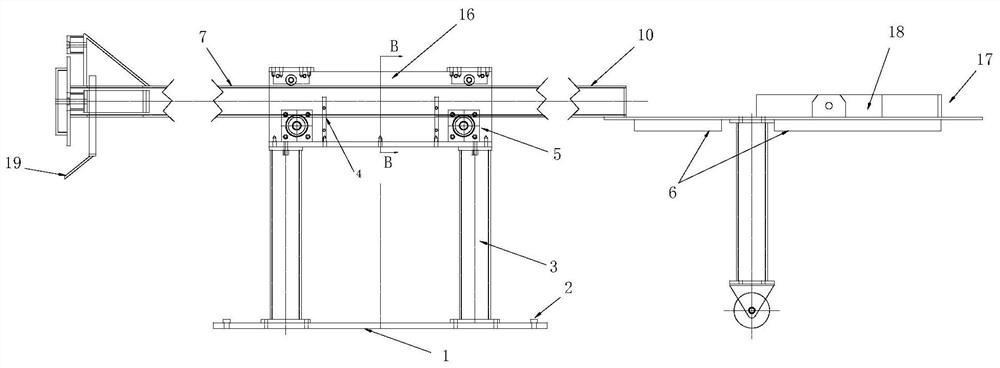

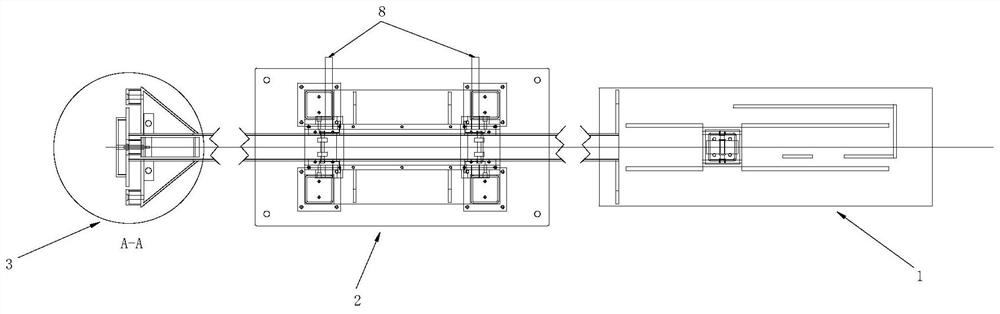

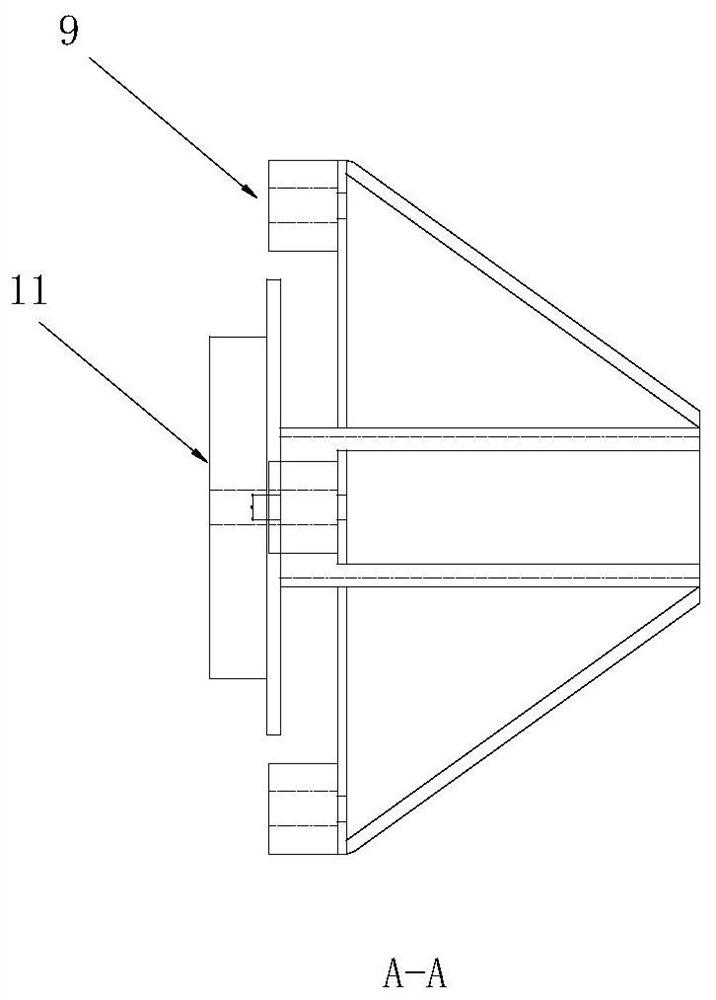

[0036] Comply with the above technical solutions, such as Figure 1 to Figure 5 As shown, this embodiment provides a cantilever type semi-automatic inner partition welding device and method, in which the inner partition is sent into the round pipe for welding under environmental factors where personnel cannot enter the round pipe.

[0037] A cantilever type semi-automatic internal partition welding device provided by the present invention includes a conveying device, a welding device, a partition fixing device and a roller;

[0038] Conveying device: fixed nut 2 fixes the bottom plate 1 of the conveyor table, the leg 3 of the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com