Double positioning mechanism for PCB numerical-control machine tool

A CNC machine tool, double positioning technology, applied in the direction of positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of time-consuming, time-consuming, low efficiency, waste of auxiliary adhesive tape, etc., to reduce workload and save auxiliary material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

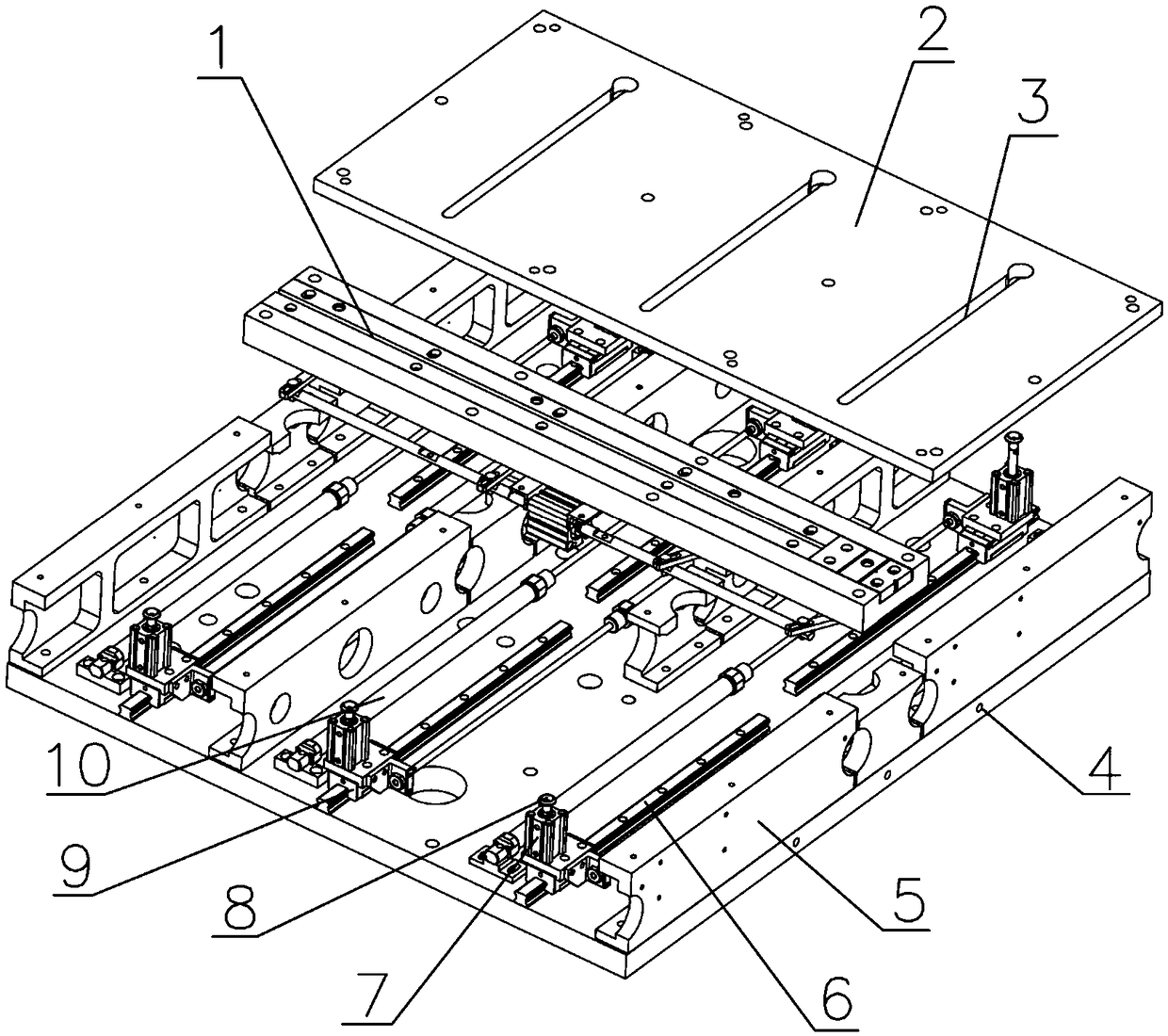

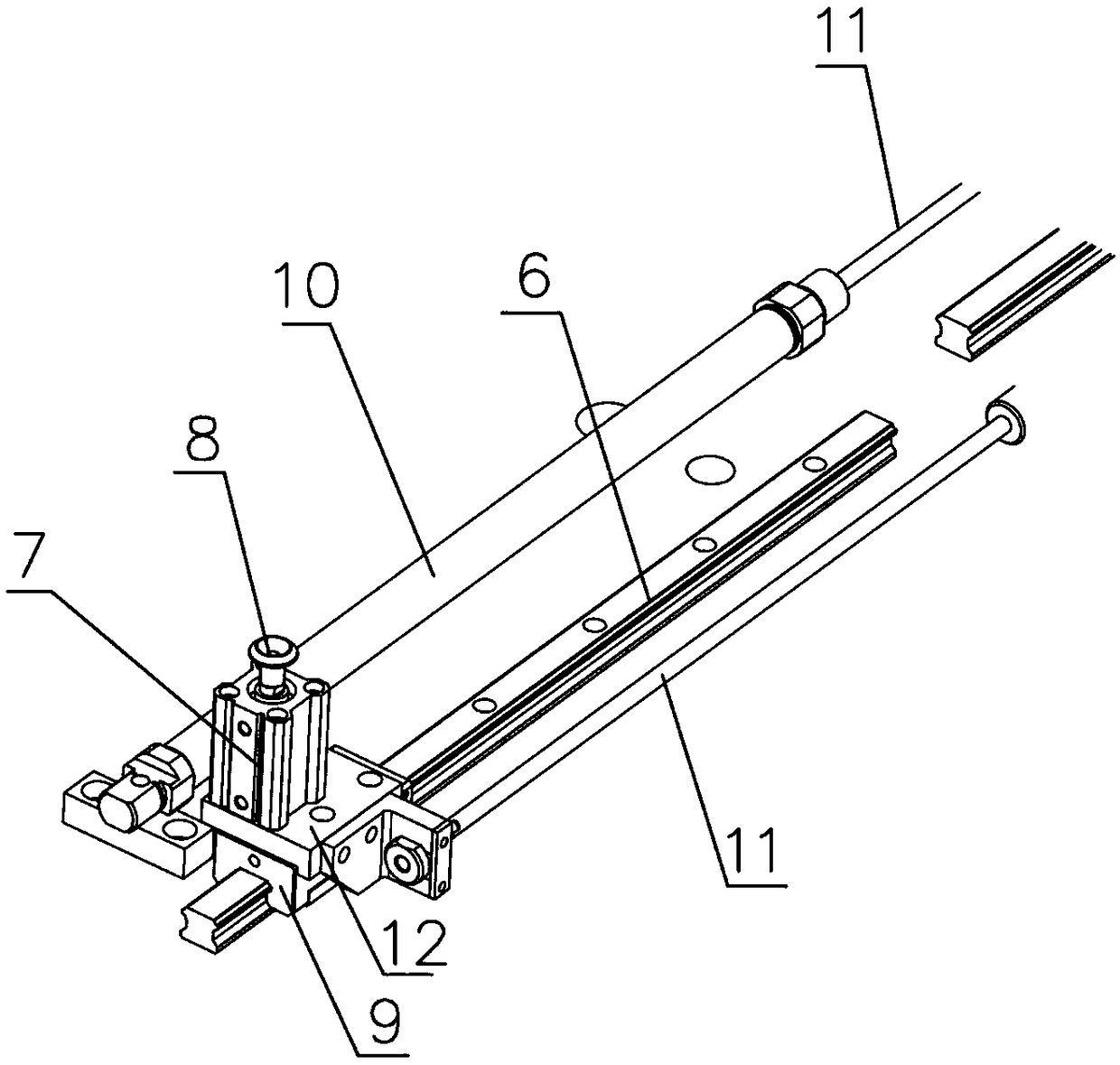

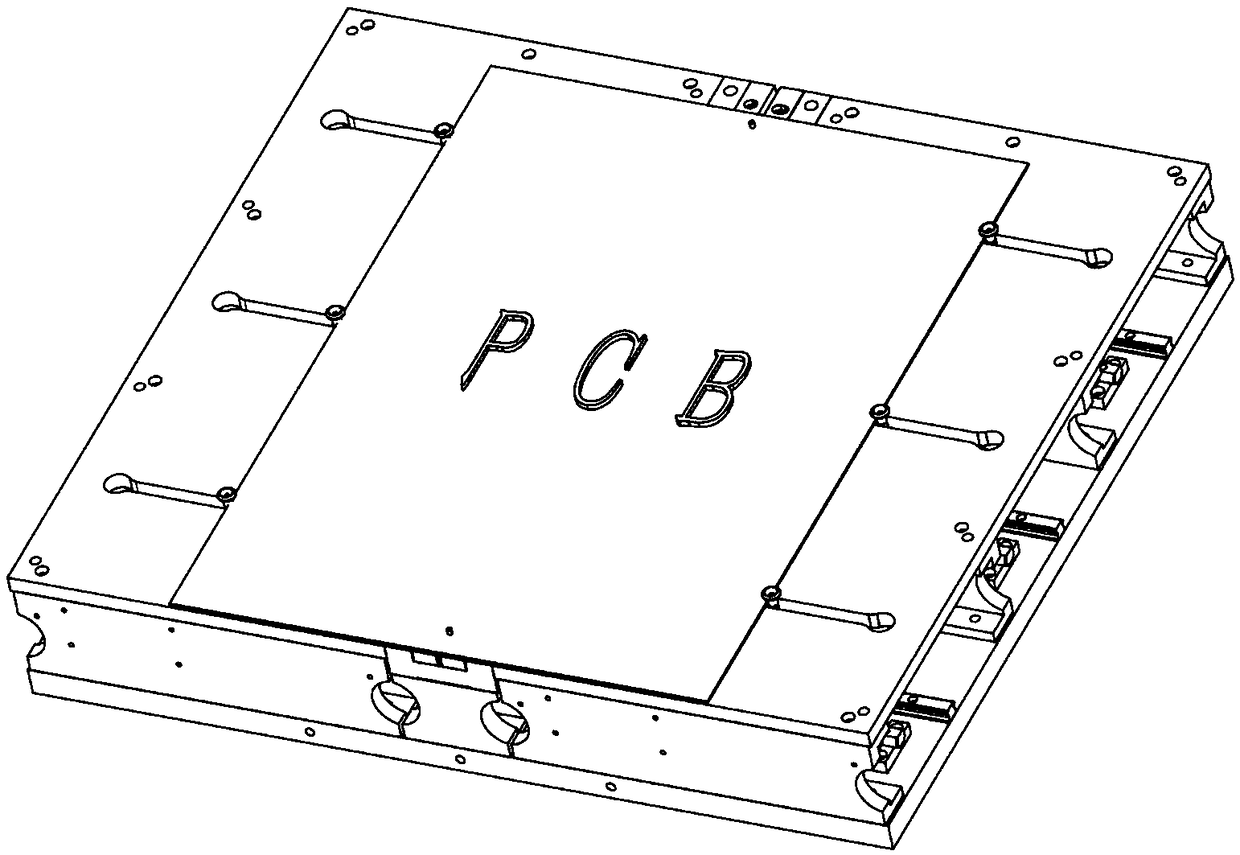

[0017] Such as figure 1 with figure 2 As shown, a dual positioning mechanism for a PCB numerically controlled machine tool has a structure including: a clamping mechanism 1 for determining the position of the PCB; auxiliary supports 5 parallel to each other are fixed on the left and right sides of the workbench bottom plate 4, so The two ends of the clamping mechanism 1 are respectively placed in the grooves in the middle of the two auxiliary supports 5. The upper surface of the clamping mechanism 1 is flush with the upper surface of the auxiliary support 5; Two workbench panels 2 are fixed on both sides of the auxiliary support 5 and above the auxiliary support 5. Each workbench panel 2 has at least one chute 3 for cooperating with the compression ring 8 to move back and forth; on the workbench panel 2 and work A fastening unit is provided in the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com