Online forming method of long fiber reinforced thermoplastic resin product

A technology to enhance thermoplasticity and thermoplastic resin, applied in the direction of coating, etc., can solve the problems affecting the mechanical properties of the product, not fully infiltrated, unable to fiber, etc., to ensure production continuity and stability, good production continuity and stability , The effect of simplifying the operation of molding processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

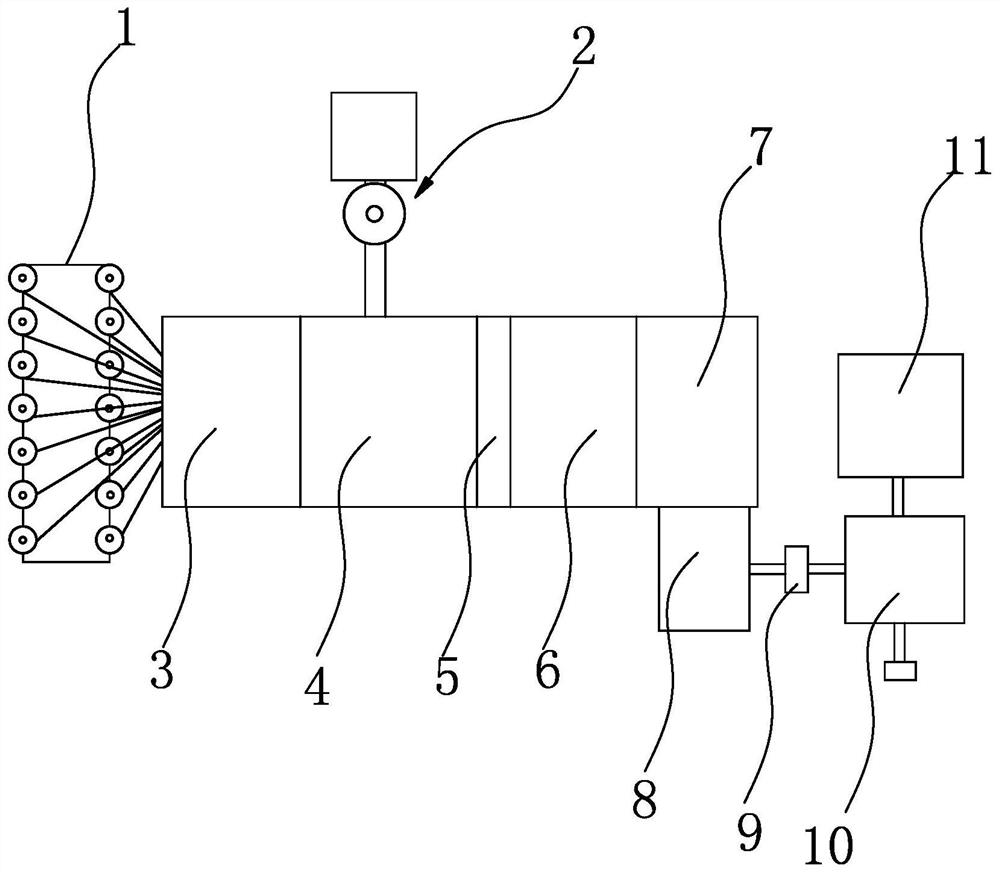

[0030] combine figure 1 As shown, the online molding method of the long fiber reinforced thermoplastic resin product is as follows:

[0031] The continuous fiber bundles of several selected bundles are unwound and pulled out from the coil on the fiber rack 1, and continuously pass through the fiber bundle dispersion and preheating treatment device 3 for preheating and dispersion treatment under the action of the traction force. It is better to enter the dispersing and preheating device 3 after being rotated and adjusted during the unwinding and pulling out process; to make all the continuous fiber bundles enter the impregnation mold 4 of the impregnation process after preheating and dispersing; the continuous fiber bundles here It is best to use one or more of carbon fiber bundles, glass fiber bundles or basalt fiber bundles, which have better reinforcing properties.

[0032]The thermoplastic resin (may include additives such as auxiliary materials and auxiliary agents) can b...

Embodiment 2

[0036] combine figure 1 As shown, the method for online forming gears of this long fiber reinforced thermoplastic resin product is as follows:

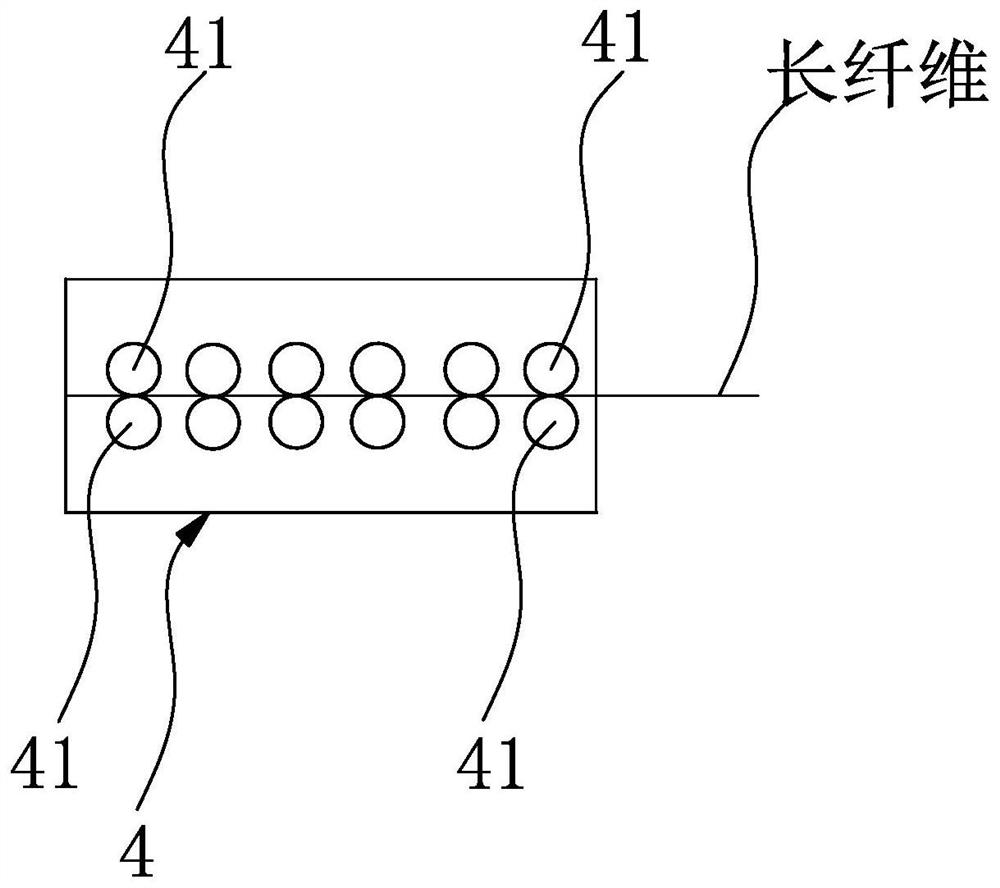

[0037] The continuous fiber bundles of 70 bundles of glass fibers are synchronously unwound, adjusted and pulled out from the coils on the fiber rack 1 to enter the dispersion and preheating device 3 for preheating and dispersion treatment. The preheating temperature here is 120°C-150°C, make all 70 bundles of continuous fiber bundles enter the impregnation mold 4 in the impregnation process after preheating and dispersion, and combine figure 2 Here, multiple groups of pressure rollers 41 are rolled in the impregnation mold 4 to roll the incoming continuous fiber bundles, preferably 6-8 groups of pressure rollers 41 are clamped up and down to be arranged in the impregnation mold 4, so that all fiber bundles are It can get the upper and lower sides of the extrusion infiltration multiple times. Other ways can also be used to repeated...

Embodiment 3

[0043] combine figure 1 As shown, the method for online forming gears of this long fiber reinforced thermoplastic resin product is as follows:

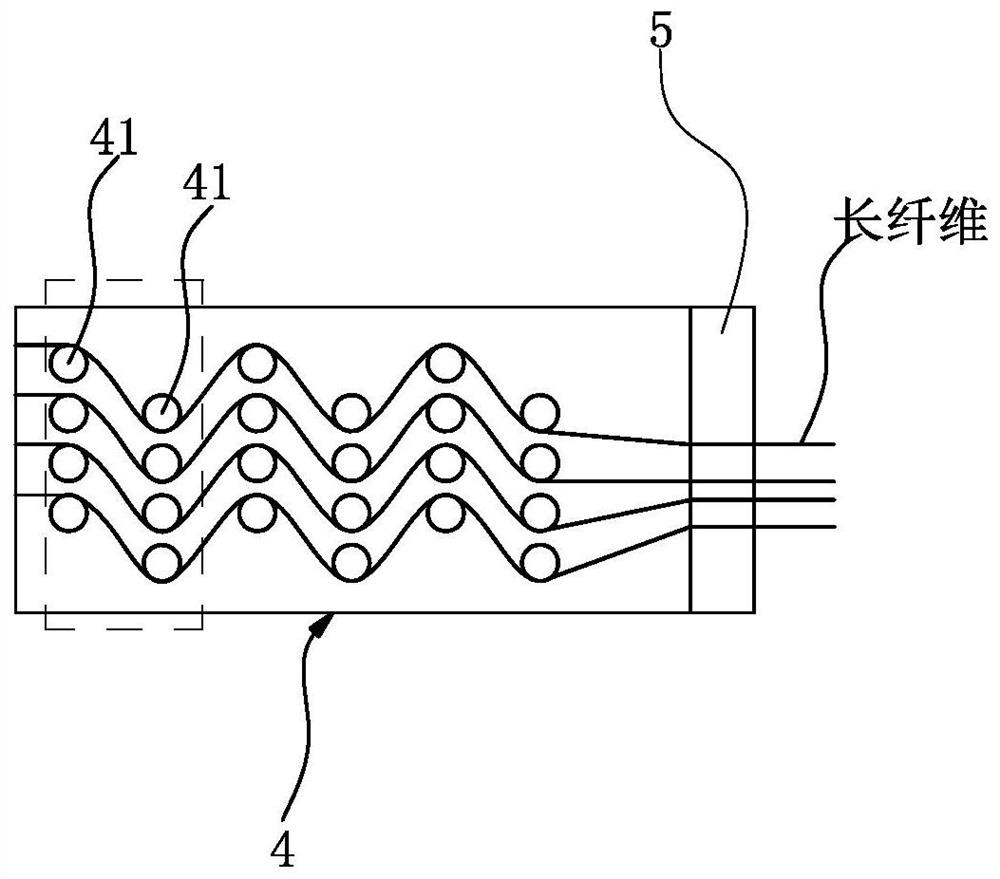

[0044] The selected continuous fiber bundles of 100 carbon fibers are synchronously unwound and pulled out from the coils on the fiber frame 1, and then entered into the dispersion and preheating device 3 for preheating and dispersion treatment. The preheating temperature here is about 120°C , make all 100 bundles of continuous fiber bundles enter the impregnation mold 4 in the impregnation process after preheating and dispersing, combine image 3 Here, multiple groups of pressure rollers 41 are rolled in the impregnation mold 4 to roll the incoming continuous fiber bundles, preferably 6-8 groups of pressure rollers 41 are arranged in the impregnation mold 4 at intervals up and down, which is equivalent to 4. Make the fiber bundle pass through in a tense front and back compression state.

[0045] Synchronously plasticize and melt th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com