Method for synthesizing analcime block material by using metakaolin

A technology of metakaolin and synthetic formula, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high price and achieve the effects of low cost, good product stability and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

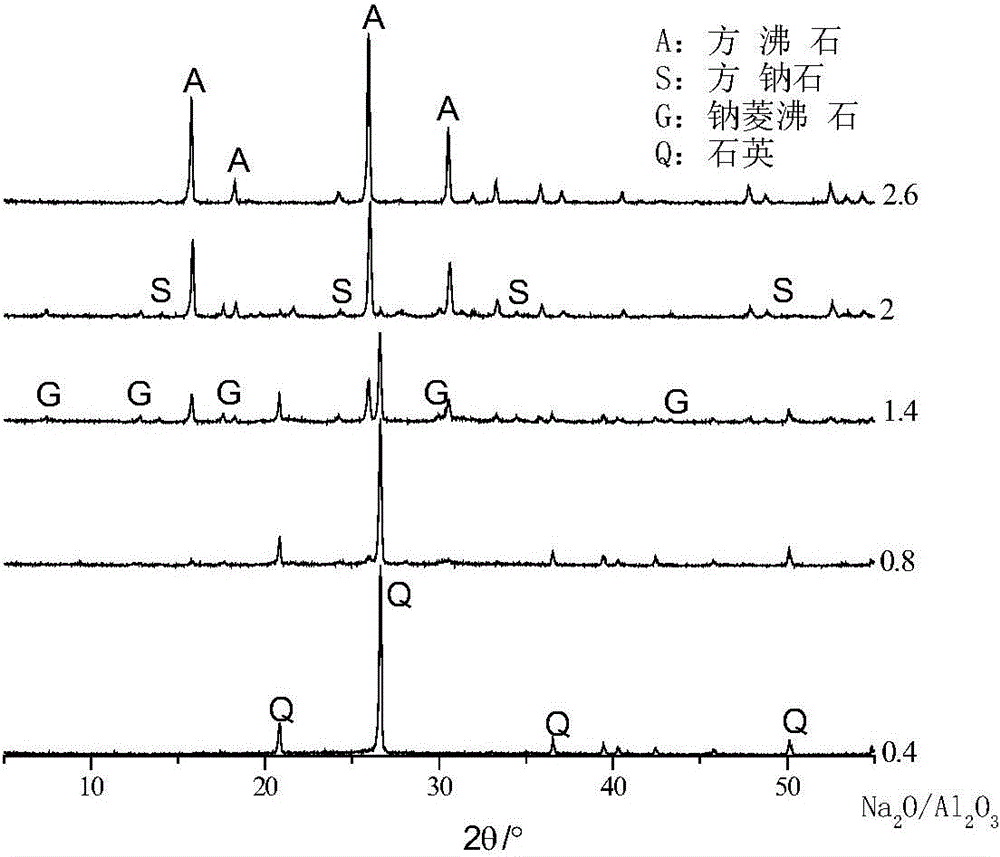

[0020] Table 1. Different Na 2 O / Al 2 o 3 Properties and components of the resulting product

[0021] Example

[0022] According to different Na in Table 1 2 O / Al 2 o 3 Measure sodium hydroxide, add distilled water to dissolve into a solution. Take 22.2g of metakaolin and 4g of quartz powder and pre-mix them in a closed container, put them in a stirring container, slowly pour the solution into the pre-mixed powder, and vigorously stir and mix to form a preparatory material. The uniformly mixed preparatory material is compressed into a green sample at 30 MPa using a powder tablet press (using the powder tablet press produced by Tianjin Sichuang Jinshi Technology Co., Ltd., hereinafter directly referred to as a tablet press). The green sample was put into an autoclave with a volume of 5 L, and treated in saturated steam at 200° C. for 12 hours to obtain an analzem block sample. Then take out the sample and dry it at 80°C for 24 hours, then transfer it to the des...

Embodiment 6-10

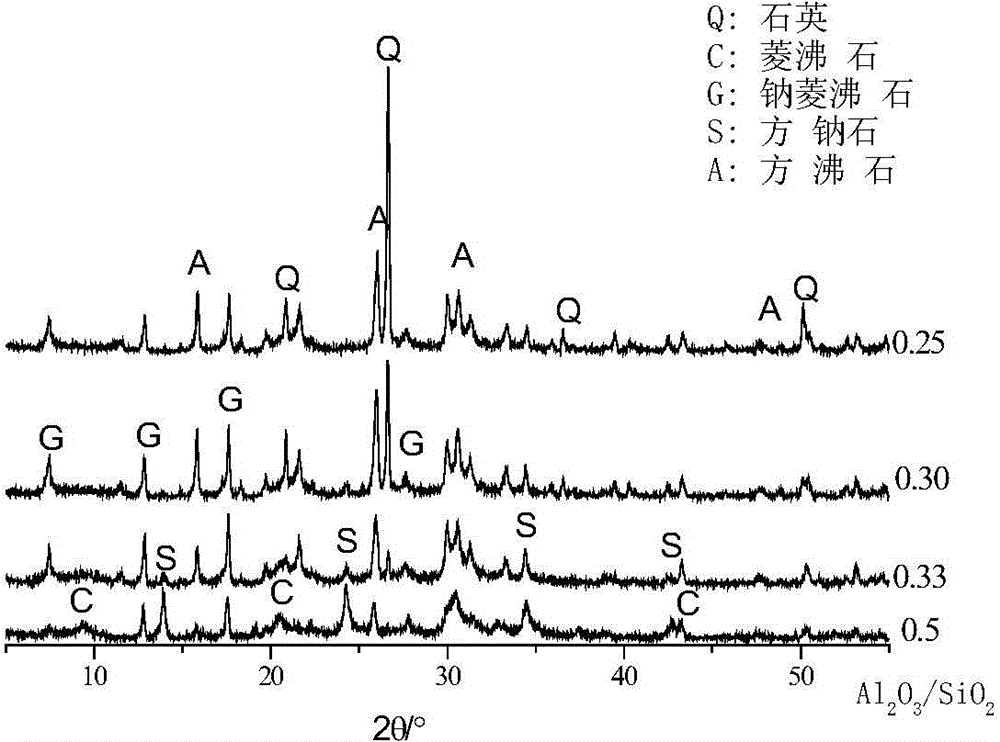

[0024] Table 2. Different Al 2 o 3 / SiO 2 Properties and components of the resulting product

[0025] Example

[0026] Measure 6g of sodium hydroxide and dissolve it into a solution with 6.64g of distilled water. Get 22.2g metakaolin, and according to table 2 different Al 2 o 3 / SiO 2 Measure the corresponding amount of quartz powder, pre-mix in a closed container, put it in a stirring container, slowly pour the solution into the pre-mixed powder, and stir vigorously to become a preparatory material. The homogeneously mixed preparatory material is pressed and formed into a billet using a press at 30 MPa. Put the blank sample into an autoclave with a volume of 5L, and treat it in saturated steam at 200°C for 12 hours; then take out the sample and dry it at 80°C for 24 hours, then transfer it to a desiccator to cool, and put it under the universal testing machine Measure its flexural strength, the test piece of destruction is ground into powder and is used for X...

Embodiment 11-14

[0028]Take 6g of sodium hydroxide, and add distilled water into sodium hydroxide to dissolve into a solution according to the different water volumes described in Table 3. Take 22.2g of metakaolin and 4g of quartz powder and pre-mix in a closed container for 5 minutes, then place in a stirring container, slowly pour the solution into the pre-mixed powder, and stir to mix. Take the uniformly mixed preparatory material, and use a press to press and shape it under 30MPa. Put the blank sample into an autoclave with a volume of 5L, and treat it in saturated steam at 200°C for 10 hours; then take out the sample and dry it at 80°C for 24 hours, then transfer it to a desiccator to cool, and put it under the universal testing machine Measure its flexural strength, and the test block of destruction is ground into powder and is used for X-ray powder diffraction analysis (XRD), and embodiment 11-14 corresponding water content and flexural strength thereof are as shown in table 3, along wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com