Method for synthesizing ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems such as difficult synthesis of ZSM-5 molecular sieve, and achieve the effect of broadening the synthesis range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

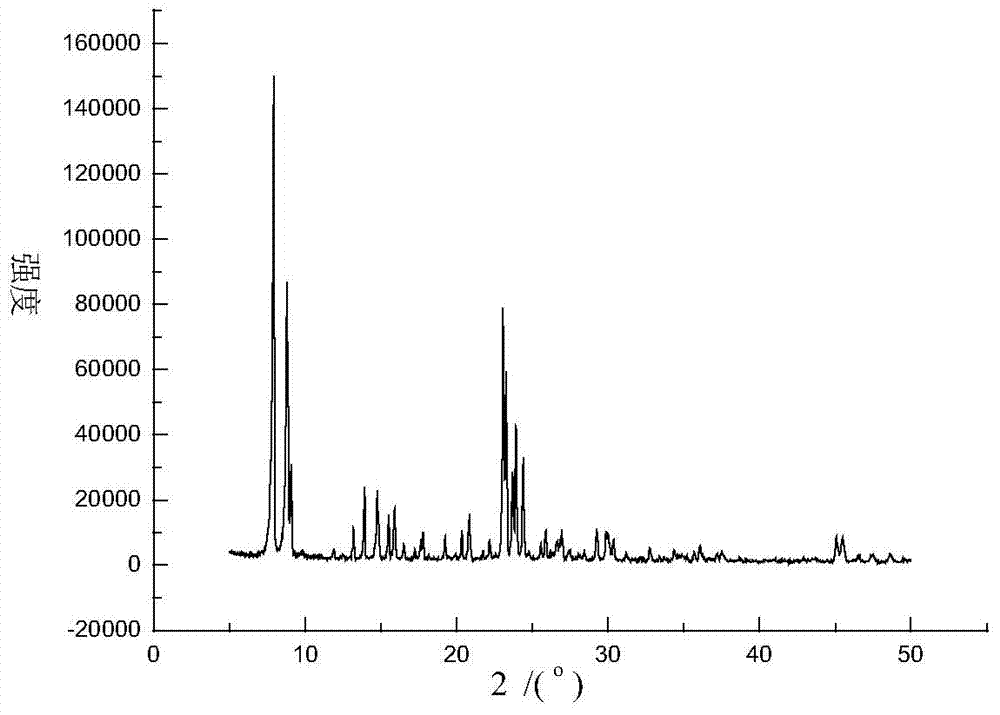

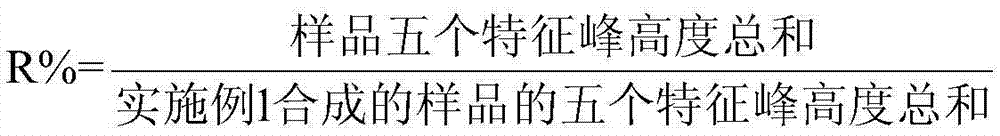

[0021] Add sodium metaaluminate and silica sol to a certain amount of deionized water, stir at room temperature until dissolved, then add tetrapropylammonium hydroxide and ethylamine under stirring, adjust the mixing with 5mol / L sodium hydroxide solution The pH of the solution is 10, and the molar ratio of the initial gel of the reaction mixture is: SiO 2 / Al 2 o 3 =50,TPAOH / SiO 2 =0.15, ethylamine / SiO 2 =0.05,H 2 O / SiO 2 =30, stirred overnight at room temperature, crystallized at 150°C for 5 hours, filtered, washed, dried, and roasted to obtain ZSM-5 molecular sieves. The XRD phase diagram of the synthesized ZSM-5 is shown in figure 1 , the crystallinity is recorded as 100%.

Embodiment 2

[0023] Add sodium metaaluminate and silica sol to a certain amount of deionized water, stir at room temperature until dissolved, then add tetrapropylammonium hydroxide and dimethylamine under stirring, adjust with 12mol / L sodium hydroxide solution The pH of the mixture is 11, and the molar ratio of the initial gel of the reaction mixture is: SiO 2 / Al 2 o 3 =10,TPAOH / SiO 2 =0.15, dimethylamine / SiO 2 =0.05, H 2 O / SiO 2 =20, stirred overnight at room temperature, crystallized at 160°C for 2 hours, filtered, washed, dried, and roasted to obtain ZSM-5 molecular sieve with a relative crystallinity of 84%.

Embodiment 3

[0025] Add aluminum sulfate and water glass to a certain amount of deionized water, stir at room temperature until dissolved, then add tetrapropylammonium bromide and diethylamine under stirring, and adjust the mixed solution with 12mol / L sodium hydroxide solution pH = 11, the molar ratio of the initial gel of the reaction mixture is: SiO 2 / Al 2 o 3 =100,TPABr / SiO 2 =0.05, diethylamine / SiO 2 =0.01,H 2 O / SiO 2 =40, stirred overnight at room temperature, crystallized at 180°C for 5 hours, filtered, washed, dried, and roasted to obtain ZSM-5 molecular sieve with a relative crystallinity of 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com