Synthetic method for MCM-22 molecular sieve

A technology of MCM-22 and synthesis method, which is applied in the field of synthesis of MCM-22 molecular sieve, can solve the problems of large dosage of template agent and long crystallization time, etc., and achieve the effect of short synthesis cycle, stable quality and broadened synthesis range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

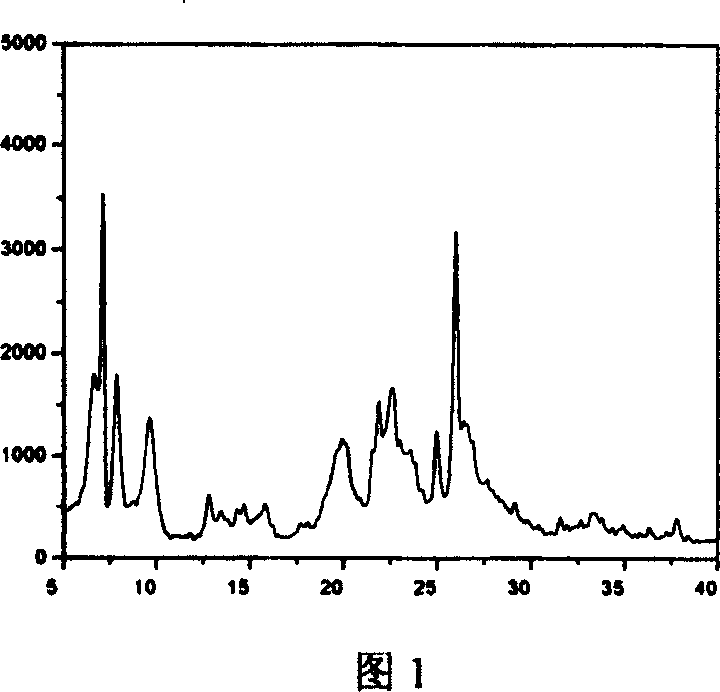

[0029] With 0.84 gram of NaOH (Tianjin Yuanli Chemical Co., Ltd., NaOH≥96.0% by weight), 1.36 gram of NaAlO 2 (Homemade, Al 2 o 3 ≥50.2% by weight), 12.5 grams of coarse-porous silica gel (Qingdao Meigao Trading Co., Ltd., SiO 2 ≥95.8 wt%) and 34.7 g H 2 O mixed to obtain a colloid. Colloids have the following molar composition: OH - :Al 2 o 3 : SiO 2 :H 2 O=0.1:0.03:1:10. The colloid was placed in an aqueous medium at 50° C. for 60 minutes with an ultrasonic wave with a power of 50 W. Cool the colloid to room temperature, add 2.25 ml of HMI (hexamethyleneimine), and stir evenly to prepare a reaction mixture. The reaction mixture has the following molar composition: OH - : Al 2 o3 : SiO 2 :R:H 2 O=0.1:0.03:1:0.1:10. The reaction mixture was transferred to an autoclave for static crystallization at 150°C for 40 hours, and then the crystallization reaction was stopped. After the product was washed and filtered, it was dried at 120°C for 10 hours to obtain MCM-22 m...

Embodiment 2

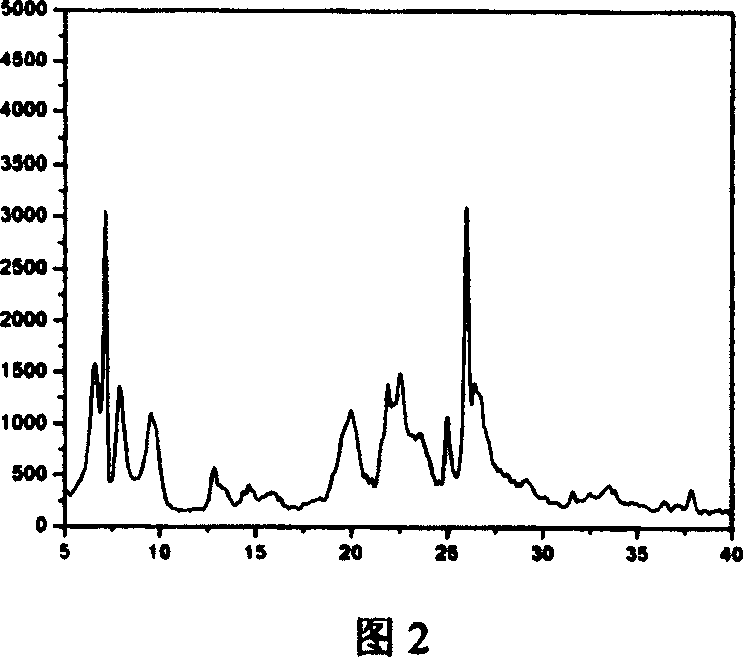

[0031] 0.41 g NaAlO 2 , 0.42 g NaOH, 28 g H 2 O and 13.8 g of silica sol (industrial grade, SiO 2 ≥43.5% by weight) mixed to obtain a colloid. Colloids have the following molar composition: OH - : Al 2 o 3 : SiO 2 :H 2 O=0.1:0.02:1:20. The colloid was placed in an aqueous medium at 40° C. for 90 minutes using an ultrasonic wave with a power of 25 W. Cool the colloid to room temperature, add 3.38 ml of HMI, and stir evenly to prepare a reaction mixture. The reaction mixture has the following molar composition: OH - : Al 2 o 3 : SiO 2 :R:H 2 O=0.1:0.03:1:0.3:20. The reaction mixture was transferred into an autoclave for static crystallization at 160°C for 60 hours, and then the crystallization reaction was stopped. After the product was washed and filtered, it was dried at 120°C for 10 hours to obtain MCM-22 molecular sieve. Its XRD spectrum is shown in Figure 2.

Embodiment 3

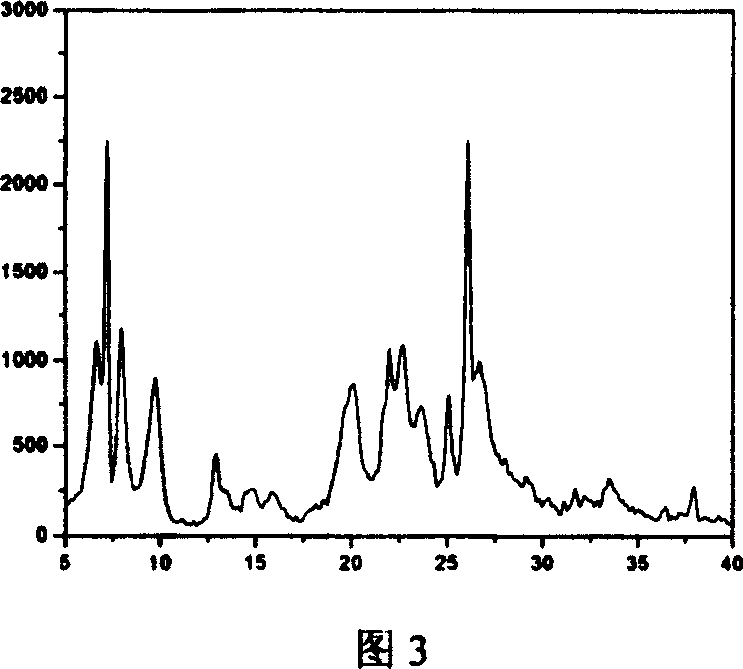

[0033] 0.81 g NaAlO 2 , 1.67 g NaOH, 287 g H 2 O and 26.2 grams of silica (Hunan Yiyang, SiO 2 ≥91.2% by weight) mixed to obtain a colloid. Colloids have the following molar composition: OH - : Al 2 o 3 : SiO 2 :H 2 O=0.1:0.01:1:40. The colloid was placed in an aqueous medium at 30° C. for 60 minutes with an ultrasonic wave with a power of 50 W. Cool the colloid to room temperature, add 22.5 ml of HMI, and stir evenly to prepare a reaction mixture. The reaction mixture has the following molar composition: OH - : Al 2 o 3 : SiO 2 :R:H 2 O=0.1:0.01:1:0.5:40. The reaction mixture was transferred to an autoclave for static crystallization at 150°C for 96 hours, and then the crystallization reaction was stopped. After the product was washed and filtered, it was dried at 120°C for 10 hours to obtain MCM-22 molecular sieve. Its XRD spectrum is shown in Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com