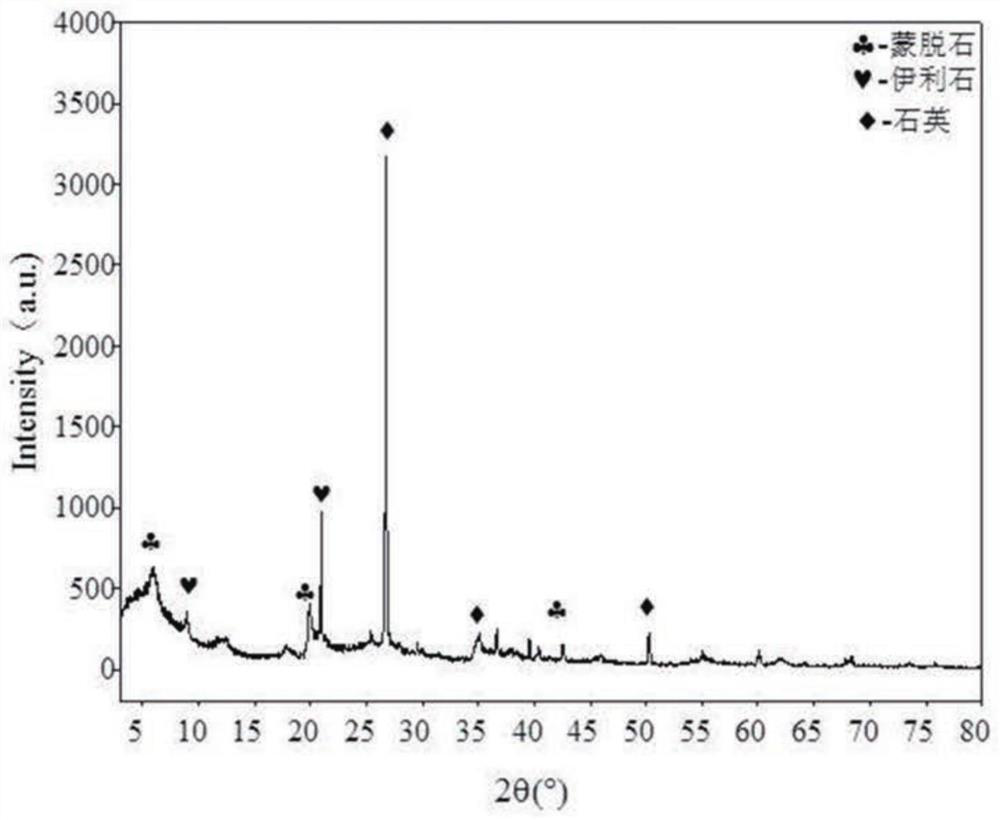

Method for synthesizing analcime from illite clay by hydrothermal alkali method and analcime

A technology of illite and clay water, applied in the field of new inorganic functional materials, can solve the problems of high energy consumption and high cost, and achieve the effects of low cost, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] (1) Press n(SiO 2 ):n(NaOH):n(A1 2 o 3 ):n(H 2 (0)=8:16:1:410, take a certain amount of illite powder, Na 2 SiO 3 9H 2 Put O and NaOH in a container, add an appropriate amount of industrial water to dissolve, age for 1.5 hours under stirring conditions until a uniform suspension of the reaction material is obtained, put the material into a closed reactor, and crystallize at 200°C for 48 hours;

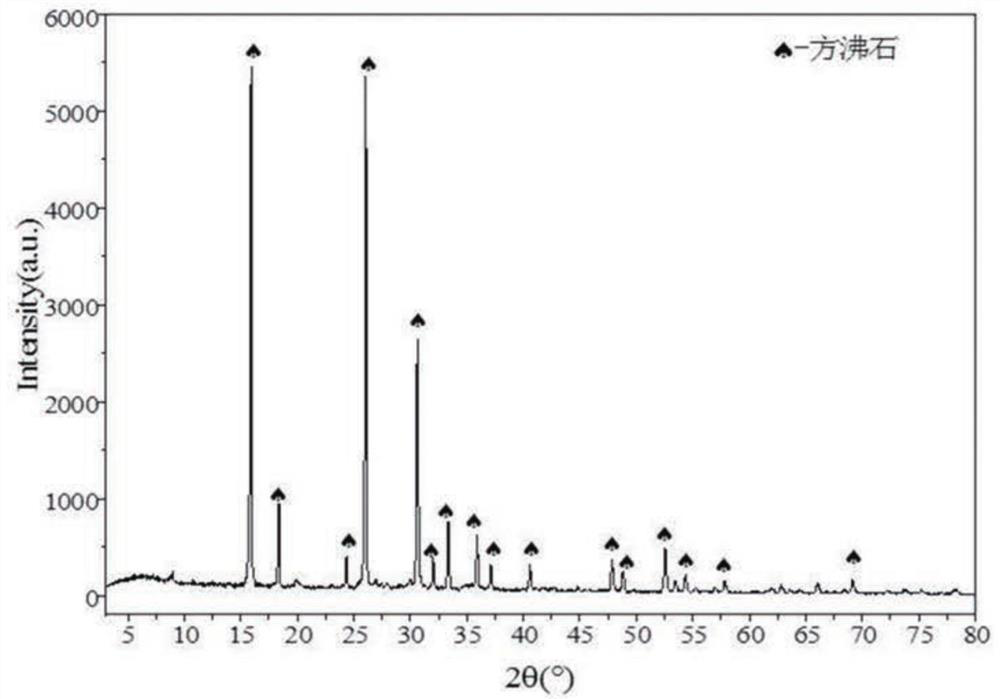

[0045] (2) The obtained product was washed 4 times with industrial water until the pH was neutral, dried at 60° C. for 8 hours, and pulverized to obtain the desired product. Its XRD spectrum is as figure 2 As shown, its SEM spectrum is shown as Figure 4 shown. in, Figure 4 The medium magnification is 2000 times. Depend on figure 2 with Figure 4 It can be seen that analzem has good crystallinity, the crystallinity is about 75%, and the crystal content is 94.7%. Compared with the ideal analzem grains, other impurities are adsorbed on the crystal surface, which is ...

example 2

[0047] (1) Press n(SiO 2 ):n(NaOH):n(A1 2 o 3 ):n(H 2 (0)=14:28:1:500, take a certain amount of illite powder, Na 2 SiO 3 9H 2 O and NaOH were placed in a hydrothermal reaction kettle, dissolved with an appropriate amount of industrial water, aged for 2 hours under stirring conditions until a uniform suspension of the reaction material was obtained, the material was put into a closed reaction kettle, and crystallized at 200°C for 48 hours;

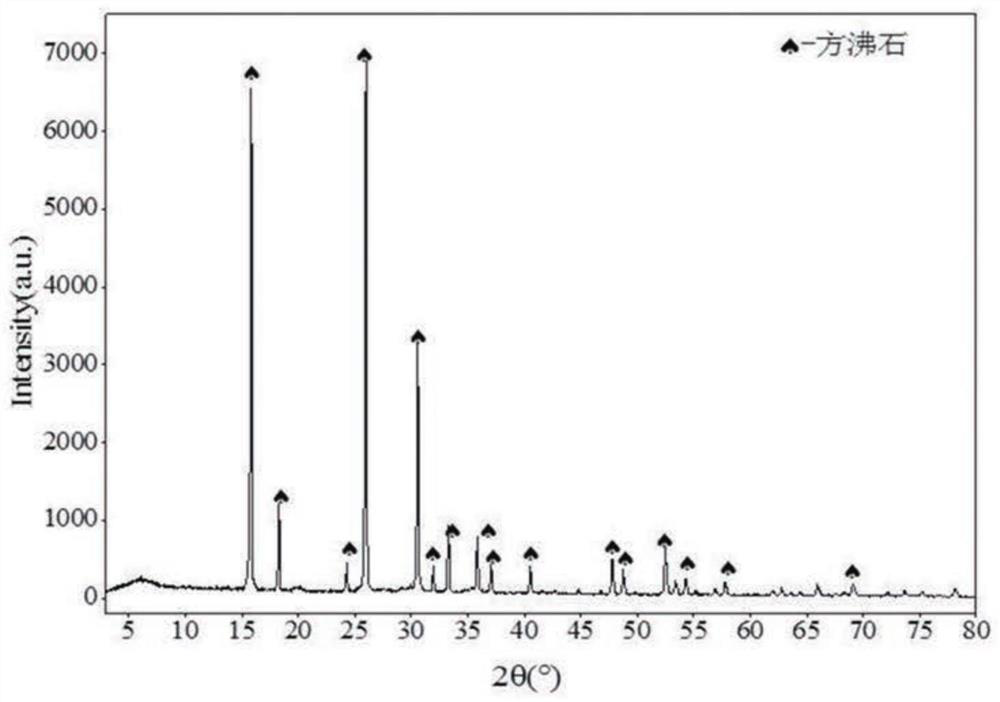

[0048] (2) The obtained product was washed 4 times with industrial water until the pH was neutral, dried at 60° C. for 8 hours, and pulverized to obtain the desired product. Its XRD spectrum is as image 3 As shown, its SEM spectrum is shown as Figure 5 shown. in, Figure 5 The medium magnification is 1000 times. Depend on image 3 with Figure 5 It can be seen that the crystallinity of analzem is good, the crystallinity is about 75%, and the crystal content is 89.3%. Compared with the ideal analzem grain, other impurities are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com