Analcite and synthesis method thereof

A synthesis method and analcite technology, which are applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problem of high cost of preparation methods, achieve simple and easy preparation methods, promote the growth of crystals, promote The effect of continuing to grow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

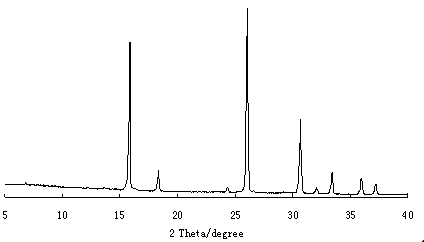

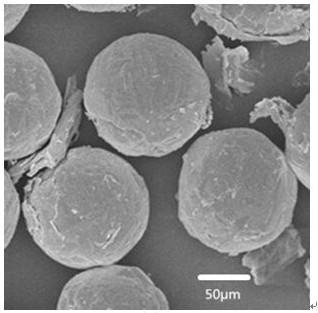

[0032] Take 5 g of sodium hydroxide and 5 g of sodium aluminate, place them in 50 mL of distilled water, and stir until all are dissolved. Add 12 g of white carbon black and mix well. Then take out 50% of the entire material and place it in an oven at 50°C for 30h. Mix well with the remaining materials. The reactant obtained in the previous step is then placed in an oven and dried at 120°C until the water is completely evaporated. Then put the resulting reactant dry glue on the upper part of the reactor, and place 15 mL of water at the bottom of the reactor (the reactor volume is 100 mL). Then the reactor was sealed and placed in an oven for crystallization at 180°C for 72 hours. The obtained product was washed 4 times with distilled water to neutral, and dried at 120°C for 12 hours. The obtained sample number was CL1. The obtained sample was as figure 1 As shown, it is pure analcime and contains no other impurities.

Embodiment 2

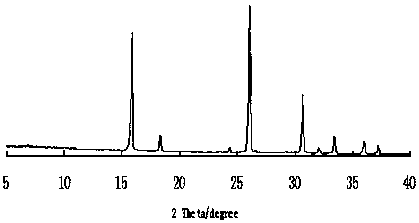

[0034] Take 4 g of potassium hydroxide and 1 g of sodium aluminate, place them in 60 mL of distilled water, and stir until all are dissolved. Add 7 g of white carbon black and mix well. Then take out 40% of the whole material and place it in an oven at 55°C for 35h. Mix well with the remaining materials. The reactant obtained in the previous step is then placed in an oven and dried at 110°C until the water is completely evaporated. Then put the resulting reactant dry glue on the upper part of the reactor, and put 5 mL of water at the bottom of the reactor (the reactor volume is 100 mL). Then the reactor was sealed, and the reactor was placed in an oven for crystallization at 170°C for 72 hours. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120°C for 12 hours. The obtained sample was analcime, numbered CL2.

Embodiment 3

[0036] Take 7 g of lithium hydroxide and 3 g of sodium aluminate into 100 mL of distilled water, and stir until all are dissolved. Add 10 g of silica gel and mix well. Then take out 45% of the entire material and place it in an oven at 60°C for 28h. Mix well with the remaining materials. The reactant obtained in the previous step was then placed in an oven and dried at 130°C until the water was completely evaporated. Then put the resulting reactant dry glue on the upper part of the reactor, and place 20 mL of water at the bottom of the reactor (the reactor volume is 100 mL). Then the reactor was sealed and placed in an oven for crystallization at 190°C for 32 hours. The obtained product was washed 4 times with distilled water to neutral, and dried at 120°C for 12 hours. The obtained sample was analcime, numbered CL3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com