Method used for illite microwave heating solid-like-phase steam conversion method synthesis of analcime

A technology of microwave heating and illite, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of environmental pollution, long synthesis time, high cost, etc., and achieve the effects of cost reduction, high value-added development, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

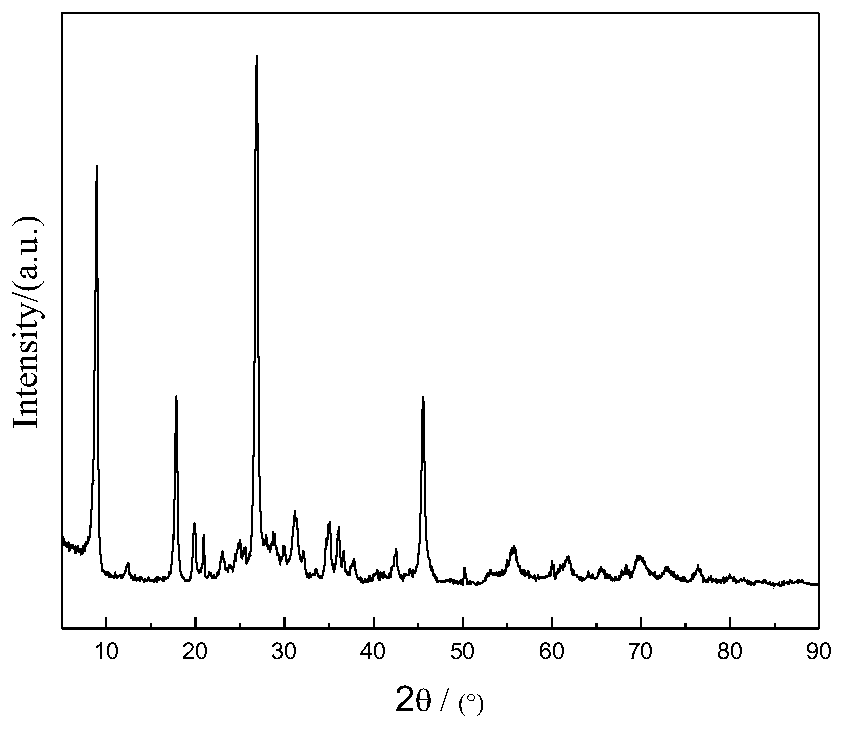

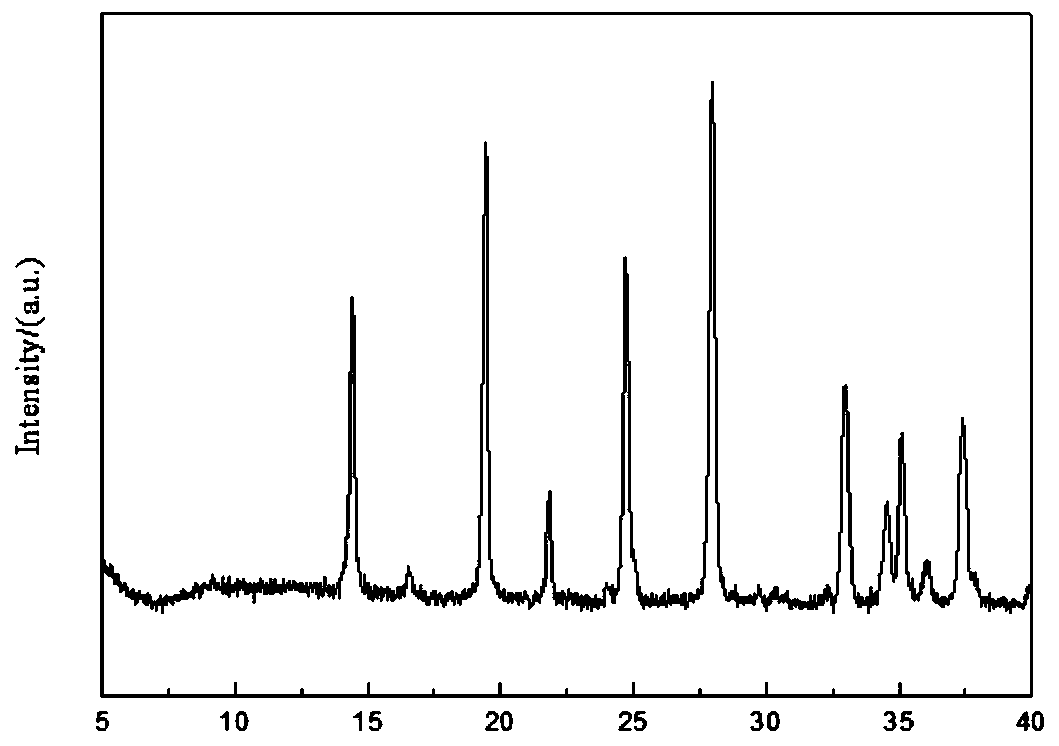

Image

Examples

Embodiment 1

[0025] A method for synthesizing analcime by illite microwave heating class solid-phase steam conversion method, is characterized in that, concrete steps are as follows:

[0026] (1), ball milling natural illite to 80 orders;

[0027] (2), sodium hydroxide and illite powder are uniformly mixed, and wherein, the mass ratio of illite and sodium hydroxide is 1:0.8;

[0028] (3), transfer the mixed material to a microwave synthesizer to synthesize analcime; the reaction conditions of the microwave synthesizer are: the temperature is 170°C, the reaction time of the mixed material in the microwave digestion tank is 15 minutes, and the microwave synthesizer The solid-to-liquid ratio of the internal solvent (water) to the mixed material is 3g / ml.

[0029] (4) The reaction product is taken out, washed until neutral, filtered, and the solid product obtained by drying is analcime powder; the filtrate is a potassium-sodium silicate mixed solution.

Embodiment 2

[0031] (1), ball milling natural illite to 200 orders;

[0032] (2), sodium hydroxide and illite powder are uniformly mixed, and wherein, the mass ratio of illite and sodium hydroxide is 1:0.8;

[0033] (3) Transfer the mixed material to a microwave digestion tank for synthesis of analcime; the reaction conditions of the microwave synthesizer are: the temperature is 100°C, the reaction time of the mixed material in the microwave digestion tank is 40 minutes, and the microwave synthesizer The solid-to-liquid ratio of the internal solvent (water) to the mixed material is 3g / ml.

[0034] (4) The reaction product is taken out, washed until neutral, filtered, and the solid product obtained by drying is analcime powder; the filtrate is a potassium-sodium silicate mixed solution.

Embodiment 3

[0036] (1), ball milling natural illite to 200 orders;

[0037] (2), sodium hydroxide and illite powder are uniformly mixed, and wherein, the mass ratio of illite and sodium hydroxide is 1:0.8;

[0038] (3) Transfer the mixed material to a microwave digestion tank for synthesis of analcime; the reaction conditions of the microwave synthesizer are: the temperature is 170°C, the reaction time of the mixed material in the microwave digestion tank is 30 minutes, and the microwave synthesizer The solid-to-liquid ratio of the internal solvent (water) to the mixed material is 3g / ml.

[0039] (4) The reaction product is taken out, washed until neutral, filtered, and the solid product obtained by drying is analcime powder; the filtrate is a potassium-sodium silicate mixed solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com