Low-temperature green synthesis method of zeolite molecular sieve material by taking southern red soil as raw material

A zeolite molecular sieve, green synthesis technology, applied in crystalline aluminosilicate zeolite, sustainable manufacturing/processing, chemical industry and other directions, can solve the problems of cumbersome preparation process and high energy consumption, achieve simple process flow, low energy consumption, widely distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of red soil synthetic analcime

[0021] (1) Naturally air-dry the red soil raw material, grind it, sieve it, wash it with pure water, dry it in an oven at 80° C., and then sieve it to obtain the pretreated red soil;

[0022] (2) Use an analytical balance to weigh the pre-treated red soil, auxiliary raw materials silicon dioxide and sodium hydroxide, add water and mix, the ratio of silicon to aluminum is (6–18):1, and the ratio of alkali to aluminum is (14 -40): 1; the amount of water added is 300%-500% of the total mass of the above-mentioned red soil, silicon source and alkali. The mixing and stirring speed is 400-800r / min, and the stirring time is 1-24 hours to obtain the reaction precursor;

[0023] (3) The reaction precursor is hydrothermally treated in saturated steam at 60°C-250°C for 5-40 hours to obtain an analcite product with a single crystal phase.

Embodiment 2

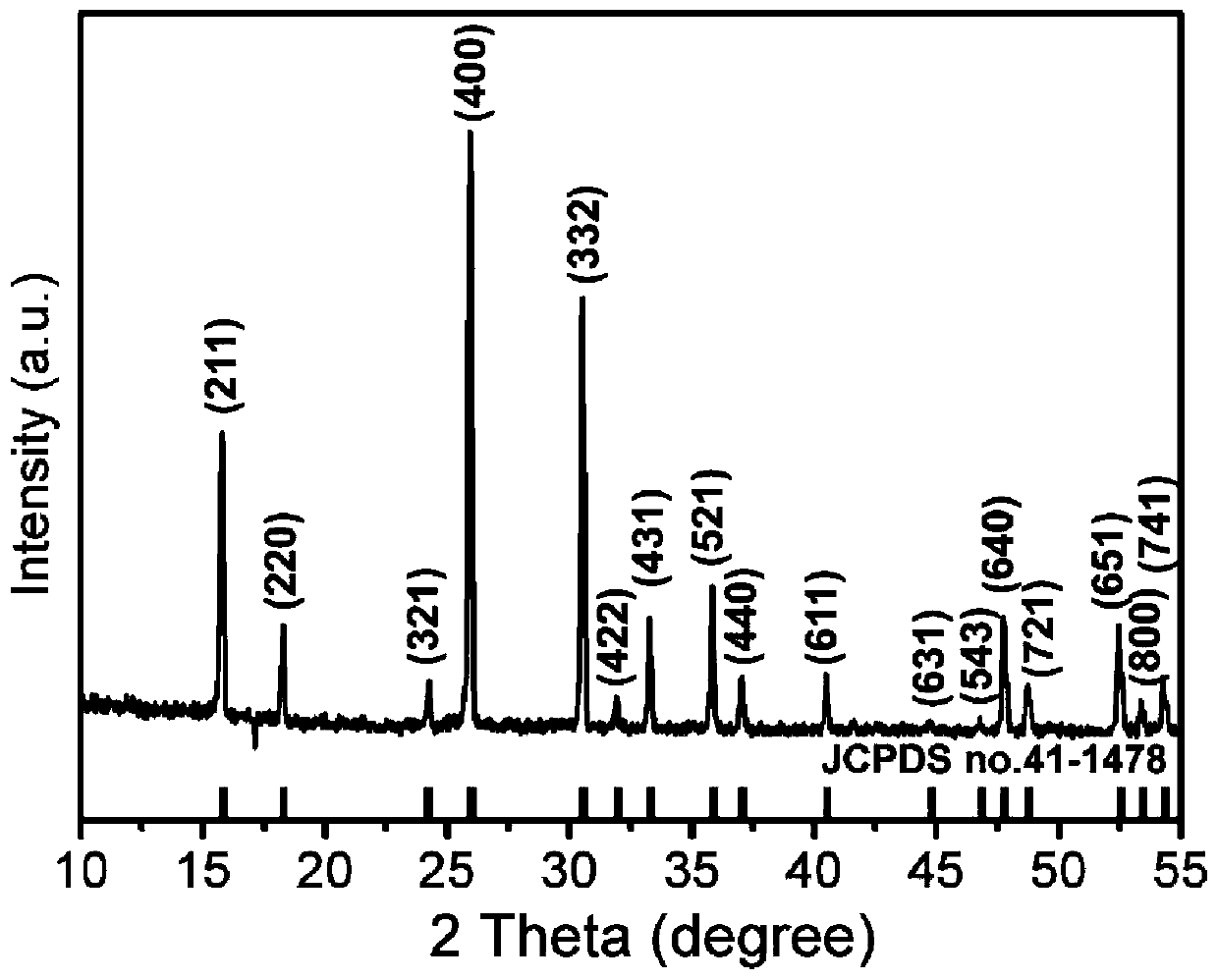

[0024] Embodiment 2: the phase characterization test of red soil synthetic analcime

[0025] Use the Rigaku SmartLab 9KW X-ray diffractometer to analyze the structure of the sample prepared in Example 1. The test condition is a fixed target monochromatic light source Cu-Kα, and the wavelength is like figure 1 The measured spectrum shown is completely consistent with the analcite crystal phase of the standard card numbered 41-1478, and no other crystal phase diffraction peaks are observed, indicating that an analcite product of a single crystal phase has been obtained.

Embodiment 3

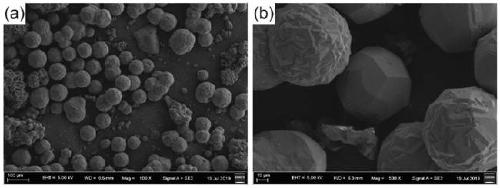

[0026] Embodiment 3: Morphological characterization test of synthetic analcime in red soil

[0027] The morphology of the sample prepared in Example 1 was characterized using a Zeiss Merlin scanning electron microscope. The test conditions were a voltage of 5 kV and a current of 100 pA. like figure 2 The morphology of analcime synthesized from red soil is shown as spherical, and the average particle size of spherical particles is 80-90 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com