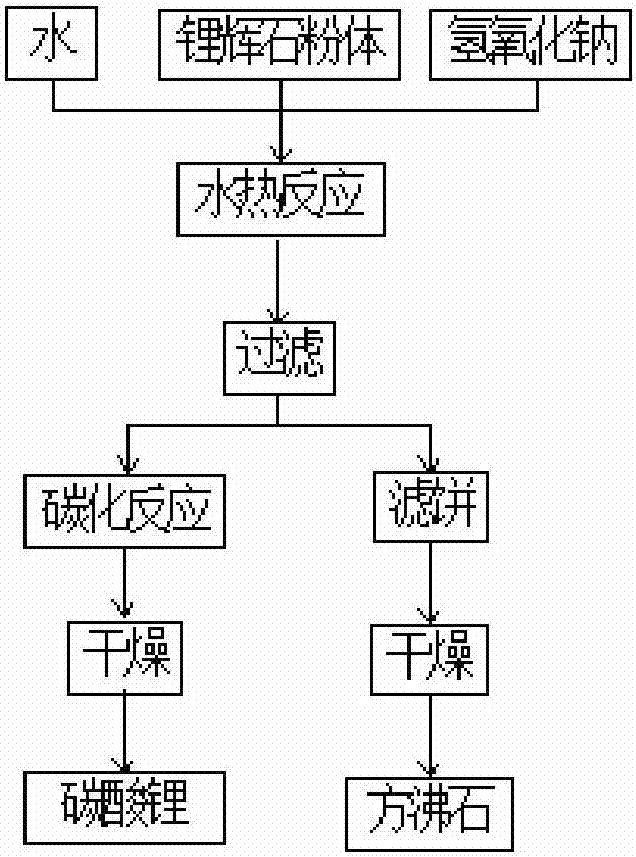

Method for preparing lithium carbonate with byproduct analcime by NaOH decomposition of spodumene

A by-product technology of analcite and spodumene, applied in the direction of lithium carbonate;/acid carbonate, aluminum silicate, silicate, etc., can solve the problem of high cost, achieve low raw material cost and reduce cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

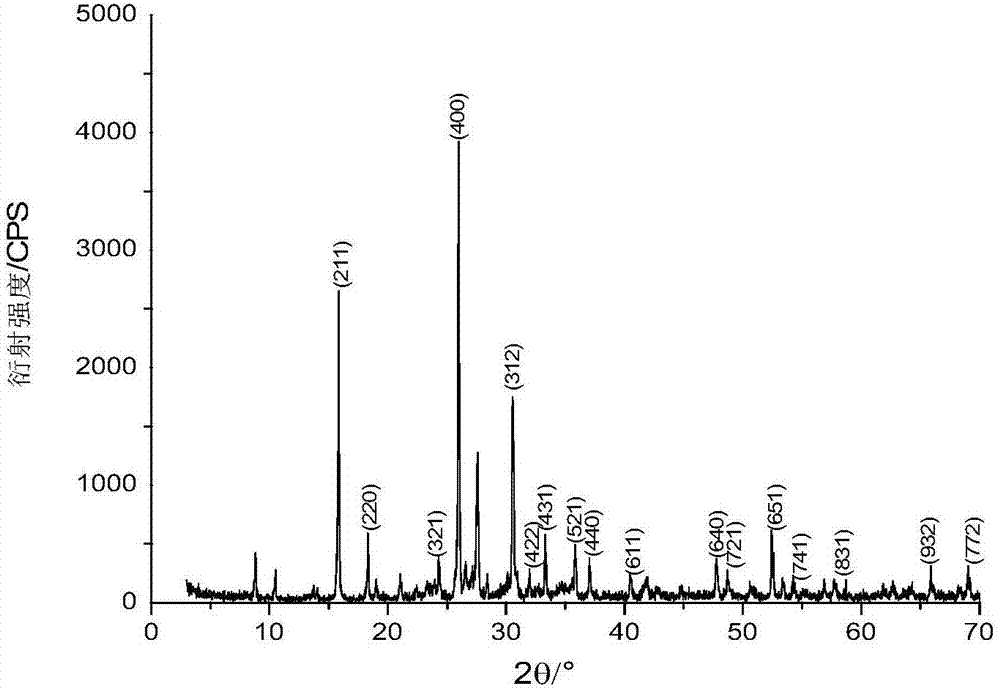

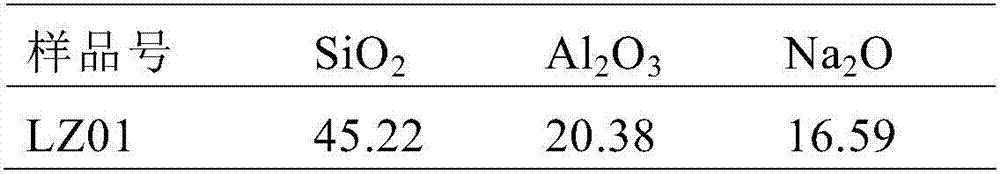

[0024] The spodumene ore is crushed, ball milled and beneficiated so that the particle size is less than 75 μm, and Li in the spodumene powder 2 O=7.0%; Weigh 8g spodumene, 2g sodium hydroxide, 80mL water, mix sodium hydroxide and water uniformly to form a sodium hydroxide solution, then add spodumene to the sodium hydroxide solution, and stir to form Mix the slurry; put it into a high-pressure reactor, heat it, react it hydrothermally at 240°C for 240 minutes, cool it down to room temperature naturally, filter it, wash it 4-5 times until the pH of the solution is 7-8, put the filter cake into Dry in an oven at 110±5°C for 12 hours to obtain analcime product; pass CO into the obtained filtrate 2 , CO 2 The ventilation flow rate is 0.2L / min, the carbonation temperature is 40°C, and the carbonation time is 90min. The obtained filter cake is washed and dried at 110±5°C for 12h, which is the lithium carbonate product. Synthetic analcime productive rate is 91%, and its product co...

Embodiment 2

[0030] The spodumene ore is crushed, ball milled and beneficiated so that the particle size is less than 75 μm, and Li in the spodumene powder 2 O=7.0%; Weigh 8g spodumene, 3g sodium hydroxide, 120mL water, mix sodium hydroxide and water uniformly to form a sodium hydroxide solution, then add spodumene to the sodium hydroxide solution, and stir to form Mix the slurry; put it into a high-pressure reactor, heat it, react it hydrothermally at 260°C for 120 minutes, cool it down to room temperature naturally, filter it, wash it 4-5 times until the pH of the solution is 7-8, put the filter cake into Dry in an oven at 110±5°C for 12 hours to obtain the analcime product. Into the obtained filtrate was passed into CO 2 , CO 2 The ventilation flow rate is 0.4L / min, the carbonation temperature is 60°C, and the carbonation time is 60min. The obtained filter cake is washed and dried at 110±5°C for 12h, which is the lithium carbonate product. The synthetic analcime productive rate is 90...

Embodiment 3

[0036] The spodumene ore is crushed, ball milled and beneficiated so that the particle size is less than 75 μm, and Li in the spodumene powder 2 O=7.0%; Weigh 8g of spodumene, 4g of sodium hydroxide, and 160mL of water, first mix the sodium hydroxide and water to form a sodium hydroxide solution, then add the spodumene powder into the sodium hydroxide solution, and stir Make a mixed slurry; put it into a high-pressure reactor, heat it, and react it hydrothermally at 280°C for 60 minutes, cool it down to room temperature naturally, filter it, and wash it 4-5 times until the pH of the solution is 7-8. Put it into an oven and dry at 110±5°C for 12 hours to obtain analcime product. Into the obtained filtrate was passed into CO 2 , CO 2 The ventilation flow rate is 0.5L / min. The carbonation temperature is 80°C, and the carbonation time is 20 minutes. The resulting filter cake is washed and dried at 110±5°C for 12 hours, and the lithium carbonate product is obtained. The synthet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com