Porous self-loading zeolite material prepared from acid-process lithium slag as well as preparation method and application of porous self-loading zeolite material

A technology of zeolite material and lithium slag, applied in the field of porous self-supported zeolite material and its preparation, can solve the problems of high porosity, low bulk density, solid waste accumulation of lithium slag by acid method, etc., achieve excellent adsorption performance, protect the environment, protect the environment The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

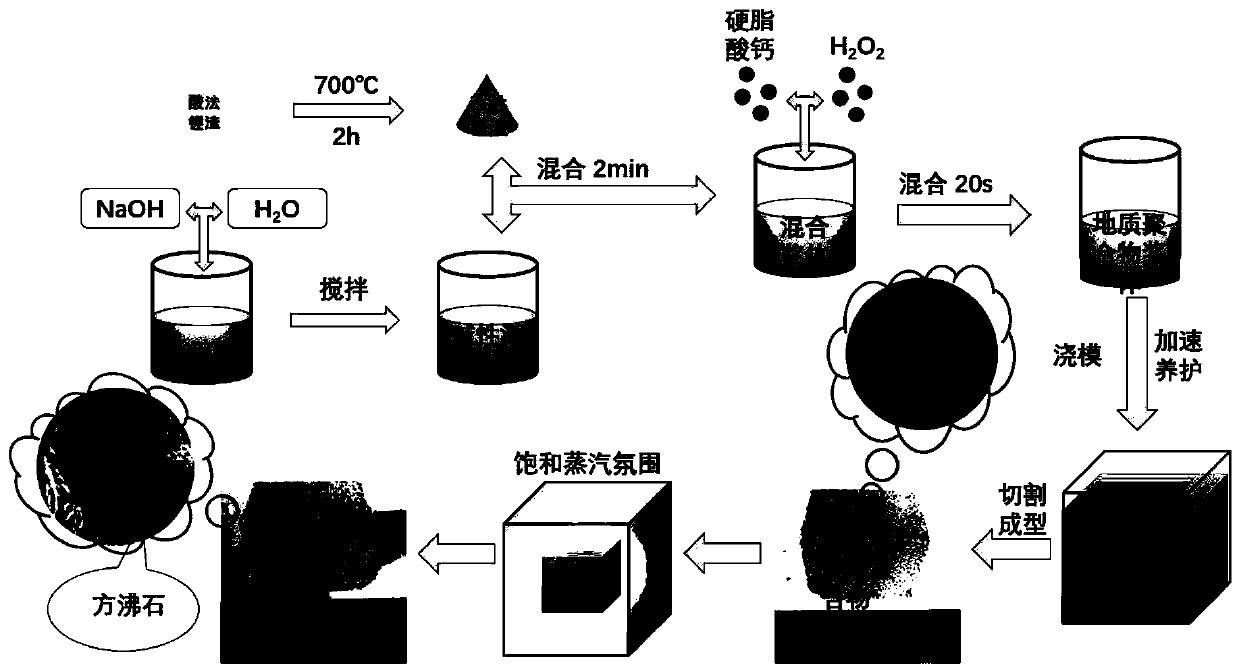

[0039] The preparation steps are shown in 1:

[0040] (1) Acid-process lithium slag powder (LS) is a finely ground powder obtained from the residue obtained after lithium carbonate is extracted from spodumene by sulfuric acid method. ) calcining at calcination temperature for 2h to obtain modified lithium slag powder, marked as MLS;

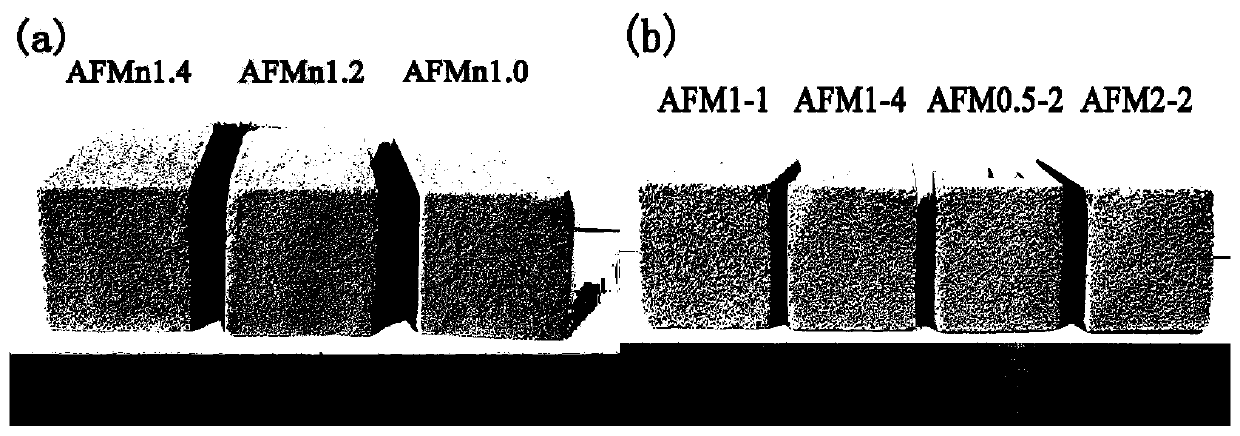

[0041] (2) Add 347g of alkaline activator (AA) to 400g of modified lithium slag powder and stir and mix for 2min, then add 10g of foaming agent and 2g of foam stabilizer to it, stir and mix well, then cast the mold, and then place the mold Curing in a concrete accelerated curing box at 70°C for 24 hours, the lithium slag-based geopolymer foam material was obtained, marked as FMn1.4; among them, the alkaline activator was composed of sodium hydroxide, water and water glass, and the modulus was 1.4; foaming agent is 35% mass concentration of hydrogen peroxide; foam stabilizer is analytically pure calcium stearate (Cs); the molar ratio of Na elemen...

Embodiment 2

[0044] (1) Acid-process lithium slag powder is a finely ground powder obtained by extracting lithium carbonate from spodumene by sulfuric acid method. The acid-process lithium slag powder is calcined at 700°C (heating rate 10°C / min). Calcined at lower temperature for 2 hours to obtain modified lithium slag powder, marked as MLS;

[0045] (2) Add 311g of alkaline activator to 400g of modified lithium slag powder and stir and mix for 2min, then add 15g of foaming agent and 3g of foam stabilizer to it, stir and mix well and cast the mold, then place the mold on the concrete to accelerate Curing at 70°C for 24 hours in a curing box, the lithium slag-based geopolymer foam material was obtained, which was marked as FMn1.2; among them, the alkaline activator was composed of sodium hydroxide, water and water glass, and the modulus was 1.2; The foaming agent is hydrogen peroxide with a mass concentration of 35%; the foam stabilizer is analytically pure calcium stearate; the molar ratio...

Embodiment 3

[0048] (1) Acid-process lithium slag powder is a finely ground powder obtained by extracting lithium carbonate from spodumene by sulfuric acid method. The acid-process lithium slag powder is calcined at 700°C (heating rate 10°C / min). Calcined at lower temperature for 2 hours to obtain modified lithium slag powder, marked as MLS;

[0049] (2) Add 275g of alkaline activator to 400g of modified lithium slag powder and stir and mix for 2min, then add 20g of foaming agent and 4g of foam stabilizer to it, stir and mix well and cast the mold, then place the mold on concrete to accelerate Curing in the curing box at 70°C for 24 hours, the lithium slag-based geopolymer foam material was obtained, which was marked as FMn1.0; among them, the alkaline activator was composed of sodium hydroxide, water and water glass, and the modulus was 1.0; The foaming agent is hydrogen peroxide with a mass concentration of 35%; the foam stabilizer is analytically pure calcium stearate; the molar ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com