Method for preparing nano analcime with fly ash

A technology of fly ash and analcime, applied in nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as crystallinity needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

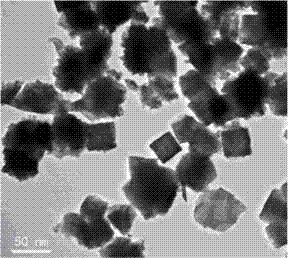

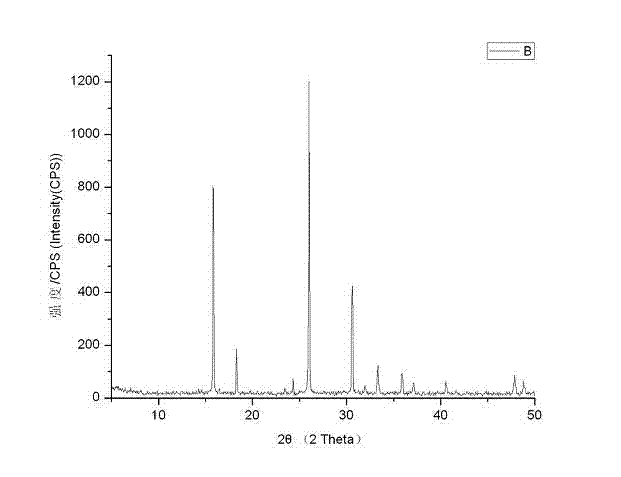

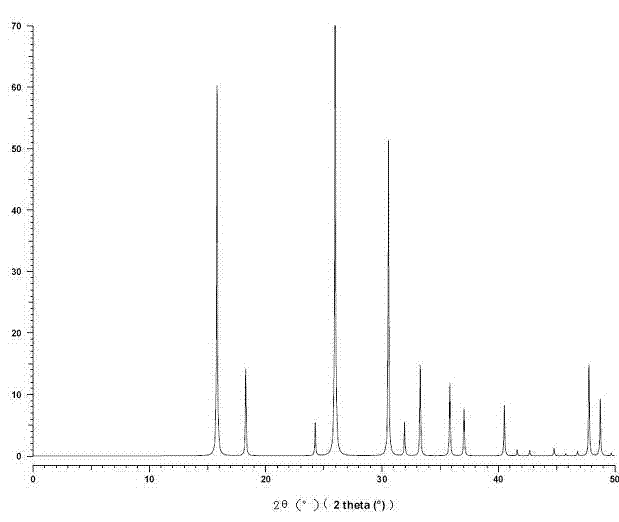

Image

Examples

Embodiment 1

[0026] Mix fly ash and sodium hydroxide, the mass ratio of sodium hydroxide and fly ash is 1.1:1, activate and roast at a high temperature of 500°C for 2 hours, after cooling, add deionized water, stir at 45°C for 3 hours, and then Stir for 7 hours; filter and dry the mixed solution after sonication for 1 hour; add 1 ml of sodium hydroxide solution with a hydroxide ion solubility of 5.5 mol / liter per 1 gram of solid, stir and sonicate for 4 hours Finally, put it in a stainless steel reaction kettle lined with polytetrafluoroethylene, at a temperature of 100 ° C, after hydrothermal crystallization for 12 hours, take out the product, filter, wash, dry, and grind to obtain a single crystal without other impurities Nanoanalcites prepared from fly ash.

Embodiment 2

[0028] Pretreat the fly ash in sulfuric acid solution, stir at 30°C for 2 hours, filter and dry, mix the pretreated fly ash with sodium carbonate, the mass ratio of sodium carbonate to fly ash is 1.8:1 , fired at a high temperature of 850°C for 1 hour, after cooling, added deionized water, stirred at 35°C for 7 hours, and then stirred at room temperature for 0.5 hour; the mixture was ultrasonically treated at 25 kHz frequency and 1000 watts for 5 minutes, then filtered and dried; Add 15 milliliters of potassium hydroxide solution with a hydroxide ion solubility of 0.3 mol / liter per 1 gram of solid to the dried solid, stir, 40 kilohertz frequency and 300 watts of ultrasonic power for 1 hour, and place the In a stainless steel reaction kettle of vinyl fluoride, at a temperature of 40°C, after hydrothermal crystallization for 96 hours, the product is taken out, filtered, washed, dried, and ground to obtain a single nano-square prepared from fly ash without other miscellaneous crys...

Embodiment 3

[0030] Pretreat the fly ash in hydrochloric acid solution, stir at 50°C for 1.5 hours, filter and dry, mix the pretreated fly ash with potassium hydroxide, the mass ratio of potassium hydroxide to fly ash is 1.5 : 1. Excited and roasted at a high temperature of 600°C for 1.8 hours. After cooling, add deionized water, stir at 100°C for 0.5 hours, and then stir at room temperature for 3 hours; Drying; add 3 ml of sodium hydroxide and potassium hydroxide mixed solution with a hydroxide ion solubility of 0.8 mol / liter per 1 gram of solid, and the mass ratio of sodium hydroxide and potassium hydroxide is 1:1 , stirring, 50 kHz frequency and 600 watt power ultrasonic for 5 minutes, placed in a stainless steel reactor lined with polytetrafluoroethylene, at a temperature of 50 ° C, after hydrothermal crystallization for 30 hours, the product was taken out, filtered, washed, After drying and grinding, a single nano analcime prepared from fly ash without other miscellaneous crystals can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com