Synthesis method of novel cathode material nano-lithium manganese stannate for lithium-ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, nanotechnology for materials and surface science, tin compounds, etc., can solve problems such as inability to mass-produce, achieve high equipment utilization, process control, shorten The effect of the transmission channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ⑴Weigh 49.02g of manganese acetate according to the element molar ratio Mn:Sn=1:1.5 and add it to 300mL deionized water to make a transparent solution, weigh 80.02g of sodium stannate and add it to 100mL of deionized water to obtain a concentrated sodium stannate solution. The sodium stannate solution was added dropwise to the manganese acetate solution to form a precipitate, and the precipitate was separated by suction filtration, washed with deionized water and absolute ethanol, and baked in a vacuum oven at 120°C for 12 hours to obtain MnSn(OH) 6 Precursor material;

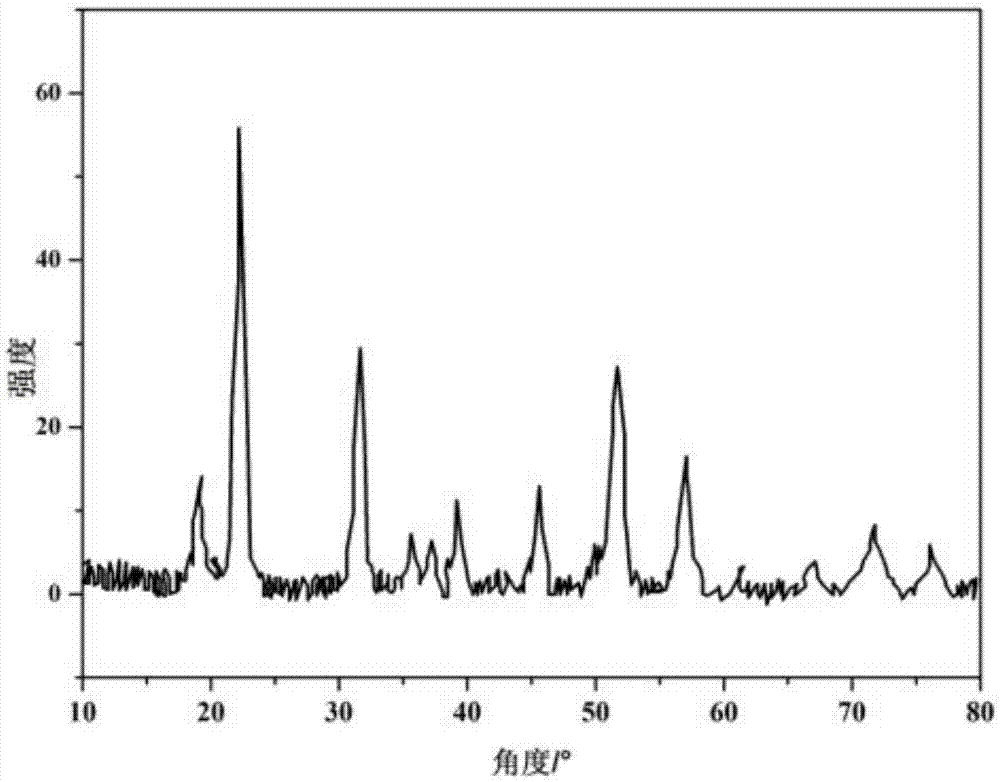

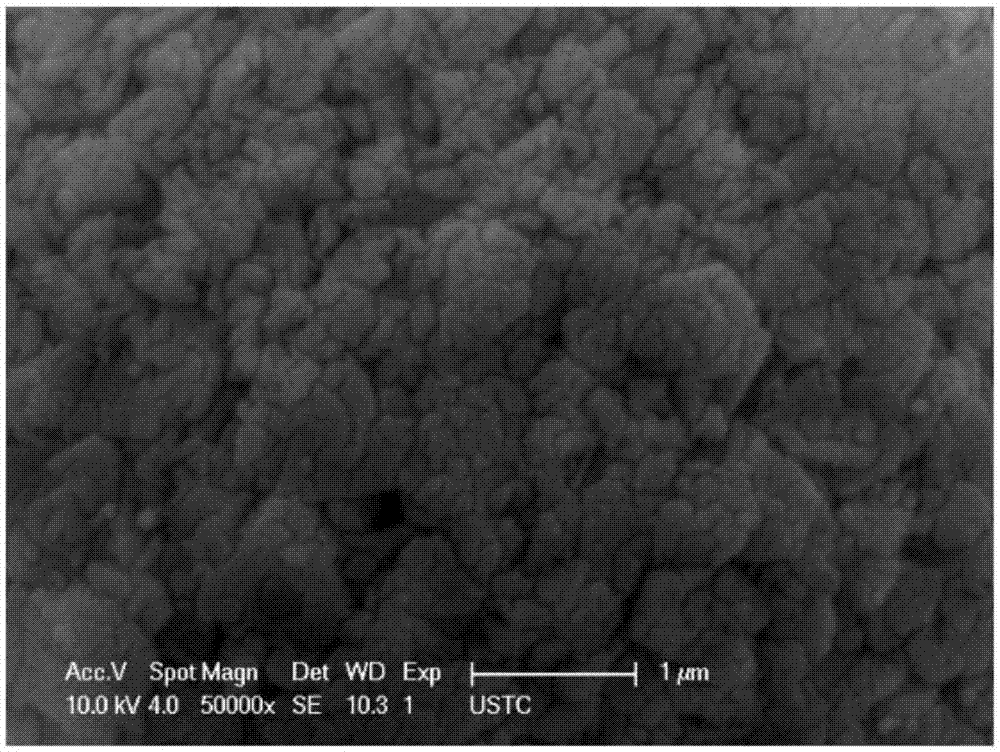

[0030] ⑵ will get MnSn(OH) 6 Precursor material in N 2 Atmosphere, calcination at 600°C for 24h to obtain nanometer MnSnO 3 Material;

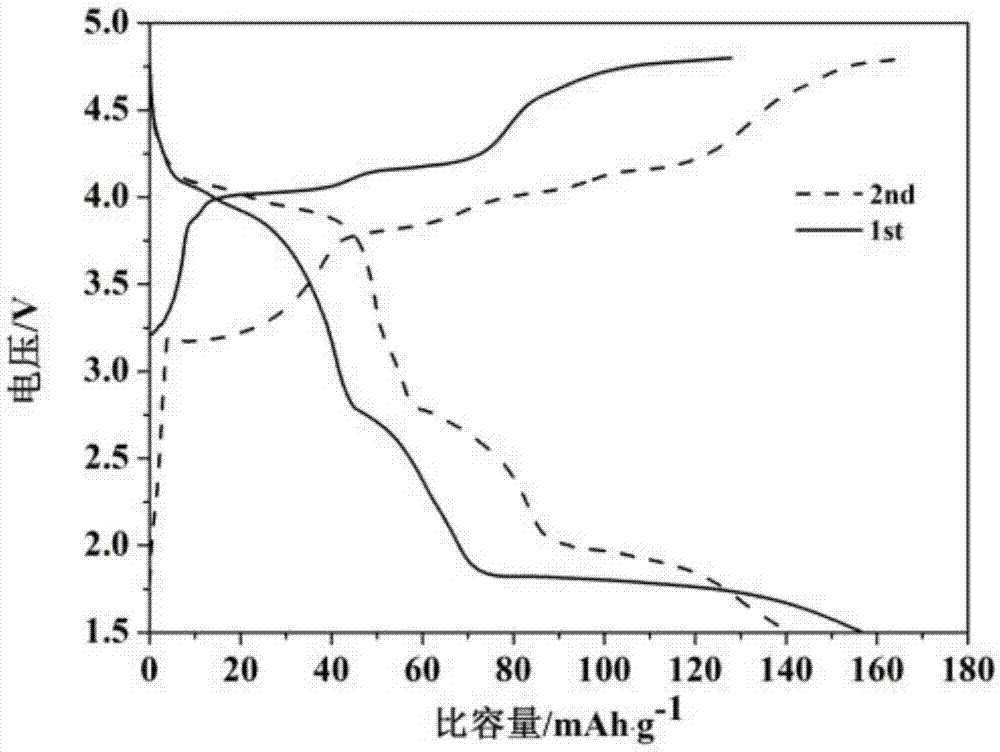

[0031] (3) According to the molar ratio of MnSnO 3 : Li=1:1.2 Weigh 33.24g nanometer MnSnO 3 Materials and 6.65g of lithium carbonate, adding 60g of ethanol as a dispersion medium, 0.4g of PEG20000 as a dispersant, prepared into a uniform slurry with a solid conten...

Embodiment 2

[0035] (1) Weigh 30.20g of manganese sulfate according to the elemental molar ratio Mn:Sn=1:1 and add it to 300mL deionized water to prepare a transparent solution, weigh 53.35g of sodium stannate and add it to 100mL of deionized water to obtain a concentrated sodium stannate solution. The sodium stannate solution was added dropwise to the manganese acetate solution to form a precipitate, and the precipitate was separated by suction filtration and washed with deionized water and absolute ethanol, then baked in a vacuum oven at 100°C for 24 hours to obtain MnSn(OH) 6 Precursor material;

[0036] ⑵ will get MnSn(OH )6 Precursor material in N 2 atmosphere, calcination at 400°C for 12 hours to obtain nanometer MnSnO 3 Material;

[0037] (3) According to the molar ratio of MnSnO 3 : Li=1:1.2 Weigh 33.24g nanometer MnSnO 3Materials and 6.65g of lithium carbonate, adding 27g of ethylene glycol as a dispersion medium, 0.2g of PEG4000 as a dispersant, prepared into a uniform slurr...

Embodiment 3

[0041] (1) Weigh 49.02g of manganese acetate according to the element molar ratio Mn:Sn=1:1 and add it to 300mL deionized water to prepare a transparent solution, weigh 53.35g of sodium stannate and add it to 100mL of deionized water to obtain a concentrated sodium stannate solution. The sodium stannate solution was added dropwise to the manganese acetate solution to form a precipitate, and the precipitate was separated by suction filtration, washed with deionized water and absolute ethanol, and baked in a vacuum oven at 100°C for 12 hours to obtain MnSn(OH) 6 Precursor materials;

[0042] ⑵ will get MnSn(OH) 6 Precursor material in N 2 atmosphere, calcination at 400°C for 24h to obtain nano-MnSnO 3 Material;

[0043] (3) According to the molar ratio of MnSnO 3 : Li=1:1 Weigh 33.24g nanometer MnSnO 3 Materials and 5.54g of lithium carbonate, adding 27g of ethanol as a dispersion medium, 0.4g of PEG20000 as a dispersant, prepared into a uniform slurry with a solid content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com