Plasma preparation technology of metal particle anti-oxidation layer

A technology of metal particles and anti-oxidation layer, used in metal processing equipment, transportation and packaging, etc., can solve the problems of easy corrosion of metal particle materials, difficult to match the thermal expansion coefficient between the anti-oxidation layer and the substrate, and poor anti-oxidation performance, and achieve large Utilize value and development prospects, improve anti-oxidation and anti-corrosion properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a high-temperature-resistant and oxidation-resistant gradient ceramic / FSA composite structure, comprising the following steps:

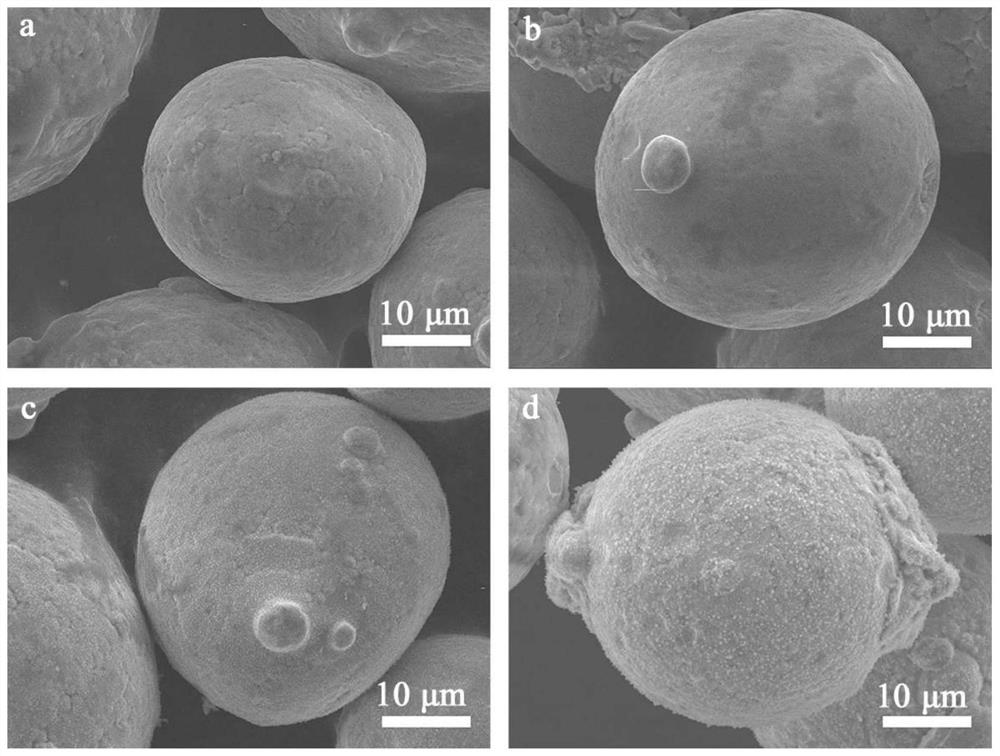

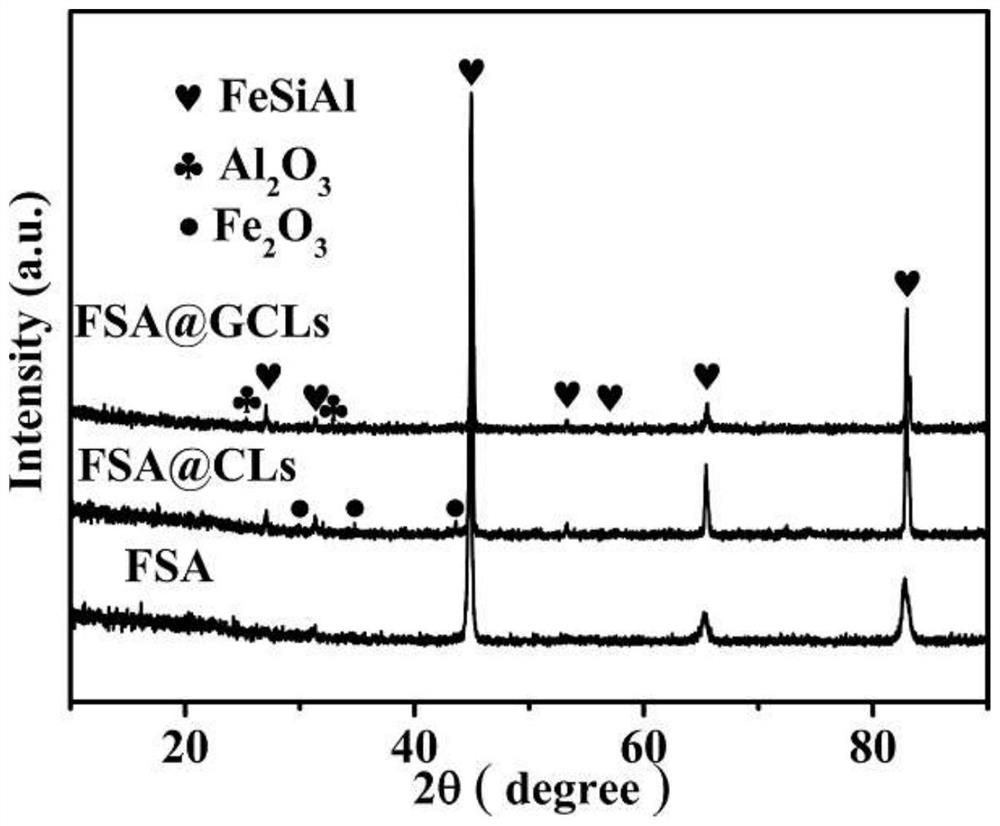

[0022] Step 1. Weigh 50g of micron-sized FeSiAl (FSA) metal particles, and oxidize it in air at high temperature to obtain a precursor material. The oxidation temperature is 700°C, and the oxidation time is 10h;

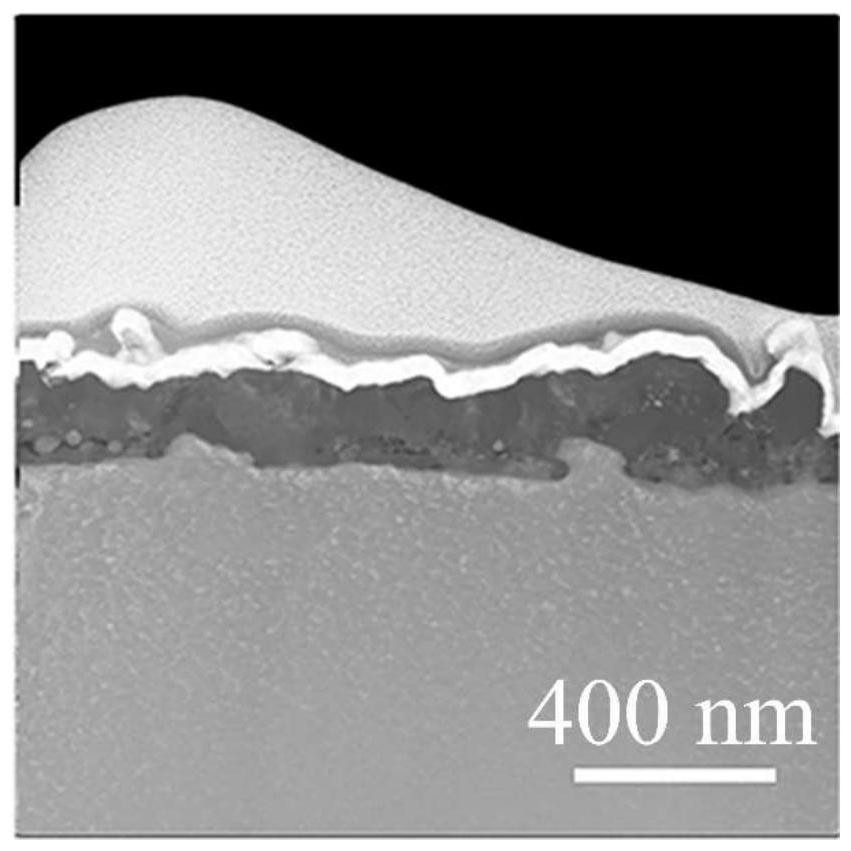

[0023] Step 2. Process the precursor material (FSA@CLs) obtained in step 1 through plasma preparation technology; specifically: place the precursor material obtained in step 1 in a CVD furnace with an argon atmosphere, and the pressure in the furnace is 95Pa, the temperature Under the conditions of 850°C and plasma power of 450W, multiple plasma reactions were carried out. The single reaction time was 60s, the interval between two reactions was 20s, and the number of reactions was 20 times. After the reaction was completed, cool naturally to room temperature and take out As a result, the gradient ceramic / FSA co...

Embodiment 2

[0026] Compared with embodiment 1, this embodiment differs in that:

[0027] In step 2, when the precursor material (FSA@CLs) obtained in step 1 is processed by plasma preparation technology, the specific process is as follows: the precursor material obtained in step 1 is placed in a CVD furnace with an argon atmosphere, and the pressure in the furnace is 95Pa, The temperature is 750°C and the plasma power is 450W for multiple plasma reactions. The single reaction time is 40s, the interval between two reactions is 20s, and the number of reactions is 20 times. After the reaction is completed, it is naturally cooled to room temperature. Taking out the product, the gradient ceramic / FSA composite structure (FSA@GCLs) can be obtained.

Embodiment 3

[0029] Compared with embodiment 1, this embodiment differs in that:

[0030] In step 2, when the precursor material (FSA@CLs) obtained in step 1 is processed by plasma preparation technology, the specific process is as follows: the precursor material obtained in step 1 is placed in a CVD furnace with an argon atmosphere, and the pressure in the furnace is 95Pa, The temperature is 800°C and the plasma power is 450W for multiple plasma reactions. The single reaction time is 40s, the interval between two reactions is 20s, and the number of reactions is 20 times. After the reaction is completed, it is naturally cooled to room temperature. Taking out the product, the gradient ceramic / FSA composite structure (FSA@GCLs) can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com