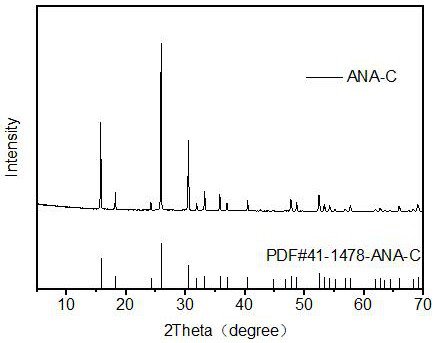

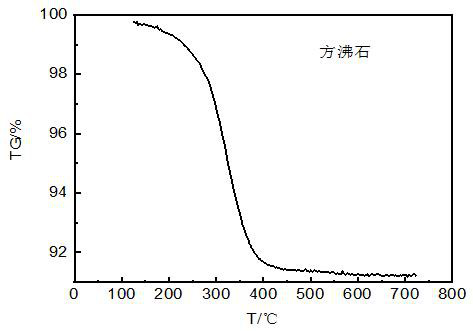

Method for synthesizing analcime by microwave hydrothermal crystallization of coal gangue

A microwave hydrothermal and coal gangue technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, chemical/physical processes, etc., can solve the problem of high cost of zeolite synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Chemical materials: coal gangue, sodium hydroxide, ethyl orthosilicate, ultrapure water. The combined preparation dosage is as follows: take gram and milliliter as the measurement unit.

[0025]

[0026] A method for hydrothermally synthesizing analcite molecular sieves using microwave activation, the steps of which are:

[0027] ① Prepare the mixed solution: weigh 0.4g of CaO ball-milled coal gangue, 1.6g of sodium hydroxide, and then add 40ml of ultrapure water into a polytetrafluoroethylene container.

[0028] ②Put the polytetrafluoroethylene container containing the mixed solution in the reaction kettle, and activate it in a microwave reactor at 160°C for 40 minutes to dissolve the active aluminosilicate.

[0029] ③ After the reaction stops, take the above-mentioned active aluminosilicate solution, add 2.4ml of tetraethyl orthosilicate, stir and age in a polytetrafluoroethylene reactor for 4h.

[0030] ④ After aging, put the polytetrafluoroethylene container in...

Embodiment 2

[0038] In order to further embody the advantages of the technical solution of the present invention, the inventors conducted a conditional study on the amount of sodium hydroxide added, and synthesized them respectively according to the parameters in Table 1.

[0039] Table 1

[0040]

[0041] Note: Low crystallinity in the table means that the test product has poor crystallinity and uneven particles; pure phase means that the test product is the target product, with uniform particles and uniform particle size.

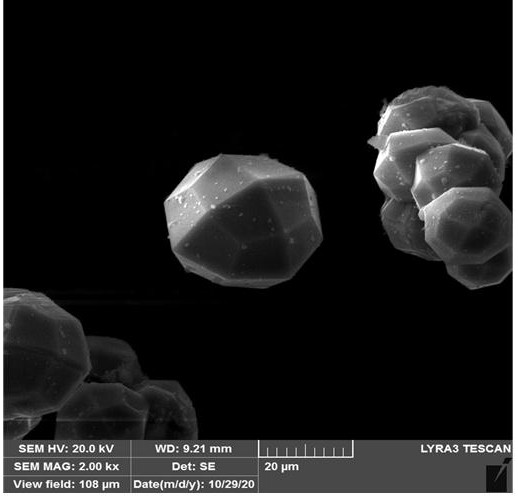

[0042] In this example, by changing the amount of NaOH to explore its influence on the dissolution of aluminosilicate in coal gangue as an alkaline activator, the results show that increasing the amount of alkali cannot synthesize pure-phase analcime. When the amount of NaOH is 1.6g, the synthesis The effect is the best, the crystal is pure and the particle size is uniform.

Embodiment 3

[0044] The inventors explored the temperature, and synthesized at different temperatures, and the final result showed that analcime, a crystal material with good crystallinity, could be successfully synthesized at 160°C. The specific experimental parameters are shown in Table 2:

[0045] Table 2

[0046]

[0047] Note: Low crystallinity in the table means that the test product has poor crystallinity and uneven particles; pure phase means that the test product is the target product, with uniform particles and uniform particle size.

[0048] In this example, by investigating the research on the synthesis of analcime at different crystallization temperatures, it was found that 160° C. is the optimum temperature for nucleation and growth of analcime crystals, and the obtained analcime crystals have high crystallinity, uniform particles, and uniform particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com