Method for producing zeolite by using soil clay minerals as raw materials

A clay mineral and soil technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of harsh reaction conditions, large energy consumption, long reaction time, etc., and achieve simple production process and economic efficiency. High, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

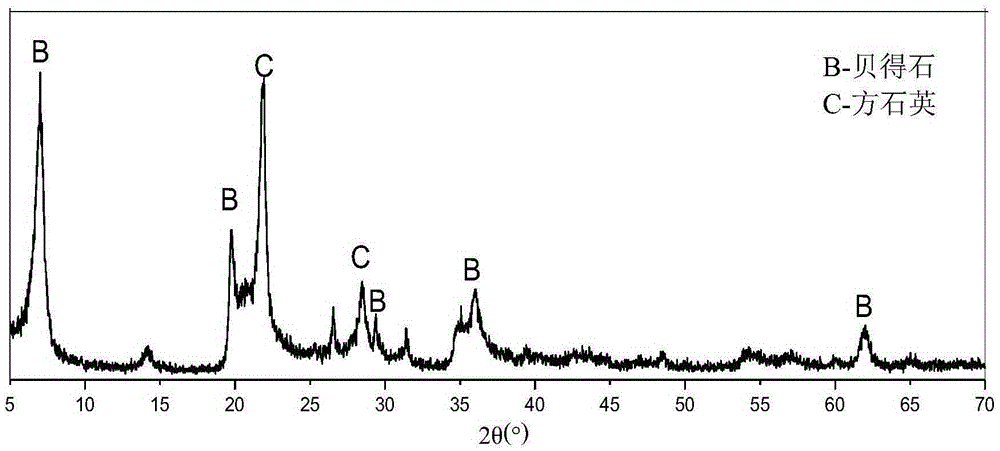

[0036] The clay mineral in this group of examples uses montmorillonite as raw material, adjusts the Na / Al molar ratio as shown in the table below, fixes the liquid-solid mass ratio at 0.5, and reacts for 12 hours under saturated water vapor at 200°C. The specific operation is as follows: according to the liquid-solid ratio (mass ratio of deionized water to dry montmorillonite raw material) is 0.5, respectively weigh deionized water and montmorillonite raw material, and weigh sodium hydroxide according to the Na / Al molar ratio in the following table , dissolved in deionized water, added to the montmorillonite raw material, stirred evenly, formed into small particles, put into a high-pressure reactor, reacted under saturated water vapor at 200°C for 12h, air-dried and then dried at 80°C for 24h to obtain reaction product.

[0037] Embodiment 1~3 raw material ratio and product composition are as shown in the following table:

[0038] Example

[0039] This group of embo...

Embodiment 4~7

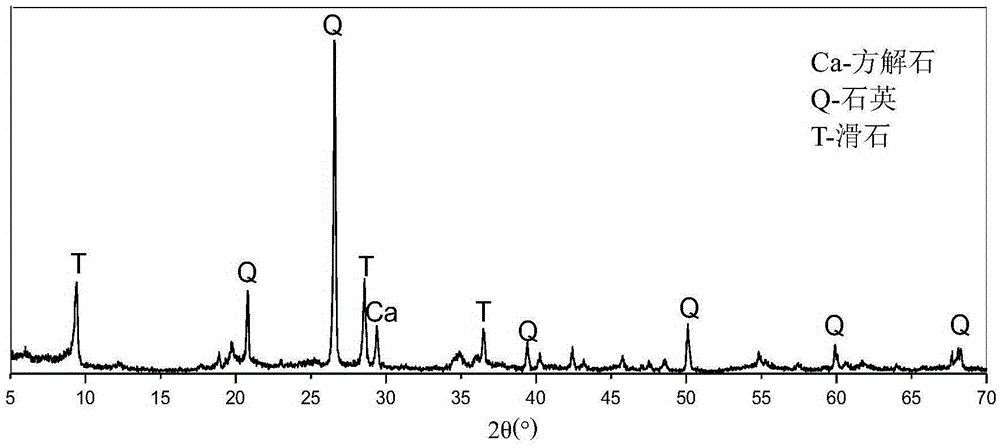

[0041] Examples 4-7 of this group use montmorillonite as raw material, the Na / Al molar ratio is 2:1, the liquid-solid ratio is adjusted according to the table below, and the reaction is carried out under saturated steam at 200°C for 12 hours. The specific operation is as follows:

[0042] Weigh deionized water and dried montmorillonite raw materials according to the different liquid-solid ratios in the table below, weigh sodium hydroxide according to the Na / Al ratio of 2:1, dissolve sodium hydroxide in deionized water and add montmorillonite In the stone raw material, stir evenly to form small particles, put it in a high-pressure reactor, react under saturated water vapor at 200°C for 12h, air-dry and dry at 80°C for 24h to obtain the reaction product.

[0043] Embodiment 4~7 raw material ratio and product composition are as shown in the following table:

[0044] Example

[0045] The X-ray powder diffraction (XRD) spectrum of the product that this group of embodiment ...

Embodiment 8~11

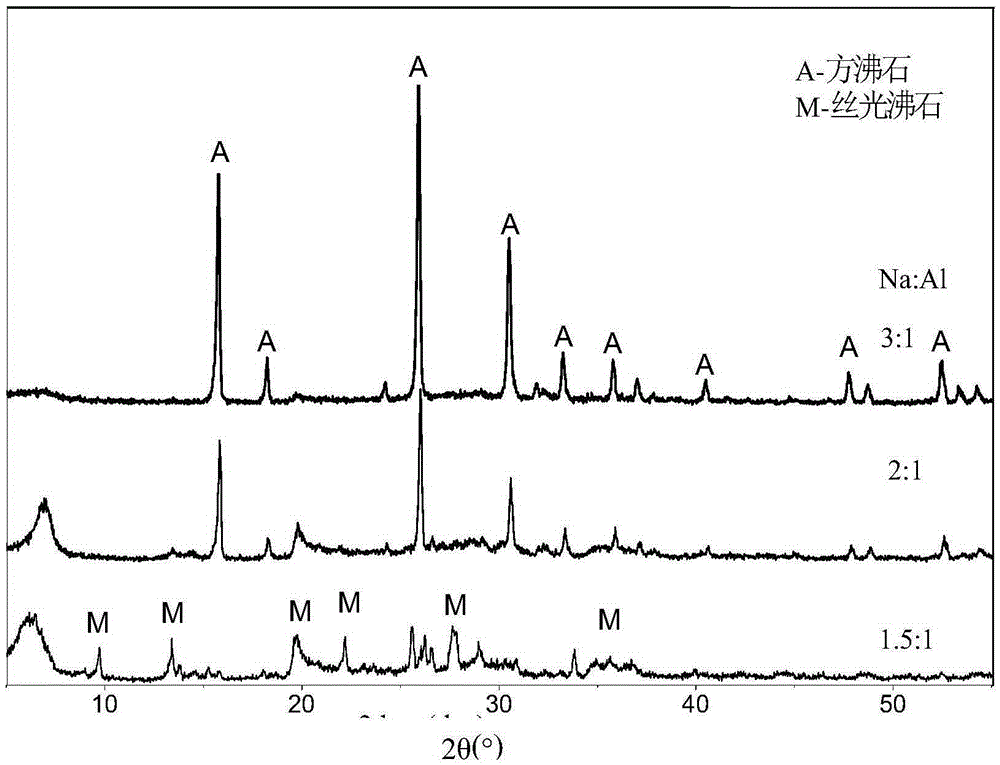

[0047] Examples 8-11 of this group use montmorillonite raw material, Na / Al in the raw material is fixed at 2:1, liquid-solid ratio is 0.5, react under saturated water vapor at 200°C, and change the reaction time as shown in the table below. The specific operation is as follows: Weigh the deionized water and the dried montmorillonite raw material respectively according to the liquid-solid ratio of 0.5, weigh the sodium hydroxide according to the Na / Al ratio of 2:1, dissolve the sodium hydroxide in the deionized water and add the montmorillonite In the destoned raw material, stir evenly to form small particles, put it into a high-pressure reactor, and react under saturated water vapor at 200°C for the different times in the table below, air-dry and dry at 80°C for 24 hours to obtain the reaction product.

[0048] Embodiment 8~11 reaction time and product composition are as shown in the following table:

[0049] Example

[0050] Embodiment 8~11 represent the X-ray powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com