Chromium slag solidification gelling polymer

A technology of coagulating polymer and curing glue, applied in cement production and other directions, can solve the problems of insignificant chromium slag, difficult innocuous treatment, complex phase composition of chromium slag, etc., and achieve good mechanical properties, high compressive strength, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

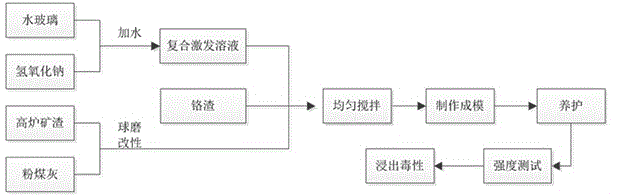

Method used

Image

Examples

Embodiment 1

[0031] The influence of different mass parts of embodiment 1 on curing effect

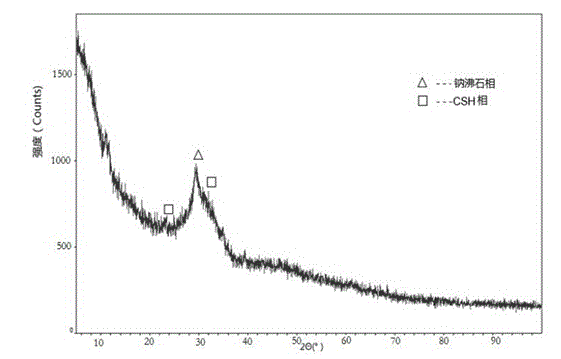

[0032] Blast furnace slag and fly ash that have been ball milled for 12 hours are dried and refined. After refinement, the particle size of chromium slag, blast furnace slag and fly ash is 200 mesh. It is made by mixing sodium hydroxide and water glass at a mass ratio of 1:1.5 Compound stimulant. According to parts by mass (35 parts, 28 parts, 25 parts, 12 parts), (45 parts, 27 parts, 18 parts, 10 parts), (55 parts, 25 parts, 12 parts, 8 parts) respectively take the above refinement The final chromium slag, blast furnace slag, fly ash, composite activator, and add water to the composite activator at a liquid-solid ratio of 0.27:1 to prepare an activator solution, and then mix the blast furnace slag, fly ash and chromium slag evenly Add the activator solution, stir evenly, and then sequentially enter the mold, solidify, demould, and maintain at a temperature of 25 ° C and a relative humidity of 90%...

Embodiment 2

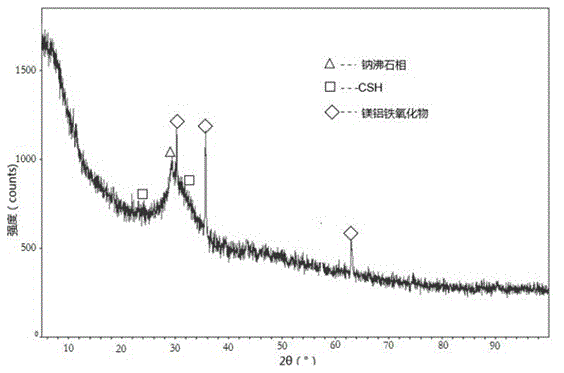

[0037] The impact of different mass ratios on the curing effect in the composite activator of embodiment 2

[0038] The blast furnace slag and fly ash that were ball milled for 12 hours were dried and refined. After refinement, the particle size of chromium slag, blast furnace slag and fly ash was 200 mesh, and sodium hydroxide and water glass were 1:1.5, 1: 2.3, 1:4 mixed to make a composite activator. Take 55 parts of refined chromium slag, 25 parts of blast furnace slag, 12 parts of fly ash, and 8 parts of composite activator, and add water to the composite activator at a liquid-solid ratio of 0.27:1 to prepare the activator solution, and then put the blast furnace After the slag, fly ash and chromium slag are mixed evenly, add the activator solution, stir evenly, and then put into the mold, solidify, demould, and maintain for 28 days at a temperature of 25°C and a relative humidity of 90% or more to obtain chromium respectively. The slag solidified gelling polymer, the pr...

Embodiment 3

[0042] The influence of embodiment 3 different liquid-solid ratios on solidification

[0043] Blast furnace slag and fly ash that have been ball milled for 12 hours are dried and refined. After refinement, the particle size of chromium slag, blast furnace slag and fly ash is 200 mesh. It is made by mixing sodium hydroxide and water glass at a mass ratio of 1:2.3 Compound stimulant. Take 55 parts of refined chromium slag, 25 parts of blast furnace slag, 12 parts of fly ash, and 8 parts of composite activator, and add water to the composite activator at a liquid-solid ratio of 0.25:1, 0.27:1, and 0.30:1. Get the activator solution, then mix the blast furnace slag, fly ash and chromium slag evenly, add the activator solution, stir evenly, then put into the mold, solidify, demould in sequence and under the conditions of temperature 25 ℃ and relative humidity above 90%. Carry out maintenance 28 days, obtain respectively chrome slag solidified gelling polymer, preparation steps are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com