Geopolymer curing material based on manganese tailings and preparation method of geopolymer curing material

A technology of curing materials and geopolymers, which is applied in the field of manganese tailings-based geopolymer curing materials and its preparation, can solve the problems of increased cement addition, high carbon footprint, and hindrance to cement hydration, and achieves internal Effects of increased friction angle, improved compressive strength, and accelerated decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

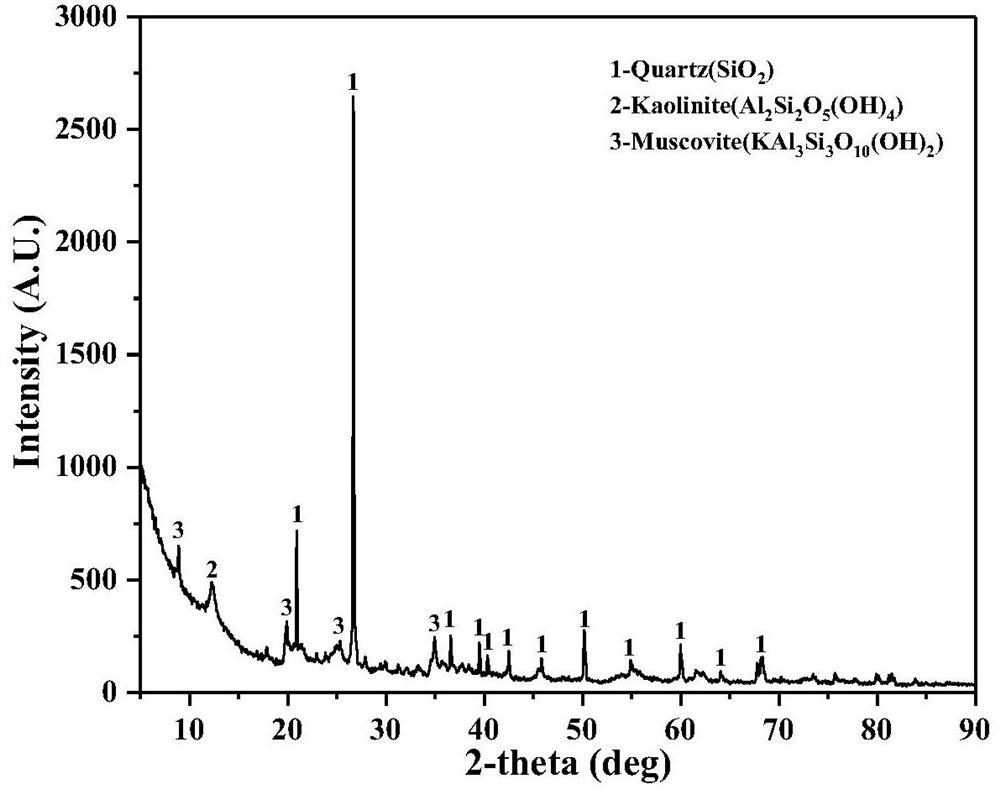

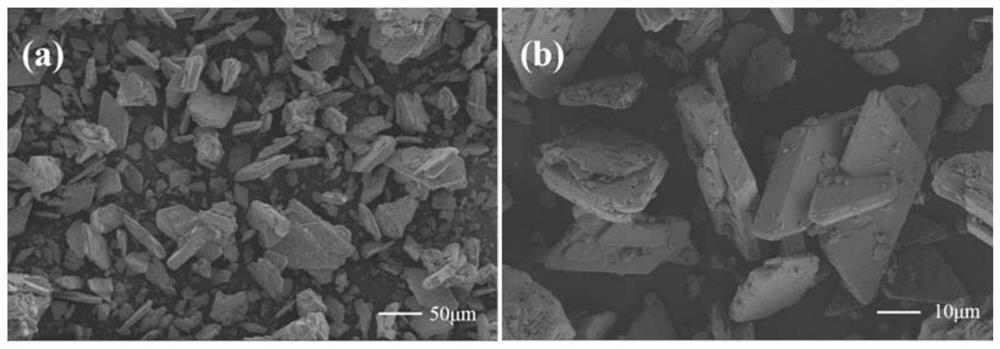

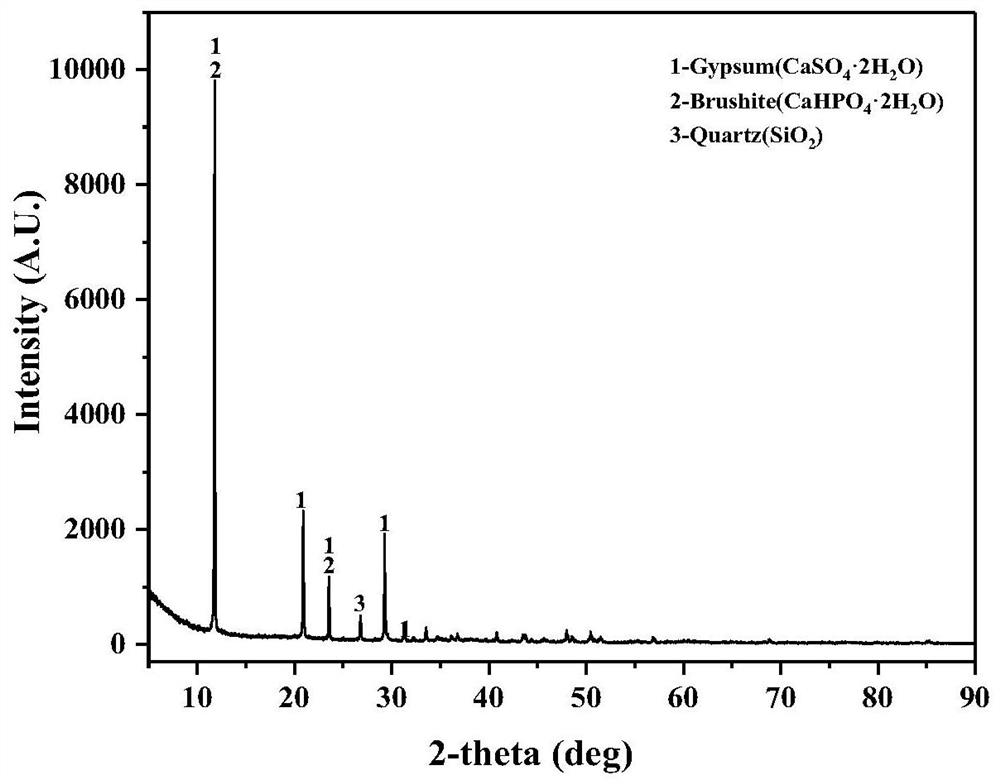

[0023] 1. Selection of raw materials:

[0024] 1. Polymetallic polluted soil

[0025] The polymetallic-contaminated soil in this example was taken from a lead-zinc smelting site in Zhuzhou City, Hunan Province. The contaminated soil was collected from the surface layer at 0-20 cm. The soil sample was mixed evenly, sand, stones, roots and other debris were removed, and the soil was passed through a 2mm sieve. Dry and set aside. The total amounts of Pb, Zn, As, and Cd in the tested soil were 2939.12, 28697.17, 566.06, and 233.45 mg / kg, respectively. The contents of these four heavy metals all exceeded the "Soil Environmental Quality Construction Land Soil Pollution Risk Control Standard" (GB36600-2018) The soil pollution risk screening value of the second type of land use needs to be repaired. The results of the leaching toxicity test of heavy metals in polluted soil showed that the leaching amounts of Pb, Zn, As, and Cd were 18.55, 665.47, 0.31, and 5.03 mg / kg, respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com