High-polymer easy plaster

A technology of beneficial clay and polymer, which is applied in the field of polymer waterproof mortar, can solve the problems of few research reports on polymer beneficial clay, uneven product quality, and a wide variety of raw materials, etc., and achieve excellent bonding strength and good impermeability , the effect of suitable coagulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of polymer beneficial clay, the raw materials used are 50kg of PO42.5 ordinary portland cement, 80kg of quartz sand (fineness 1.0mm), 25kg of ash calcium powder (its Ca(OH) 2 The content is 92%), PVA24887kg, redispersible latex powder 2kg.

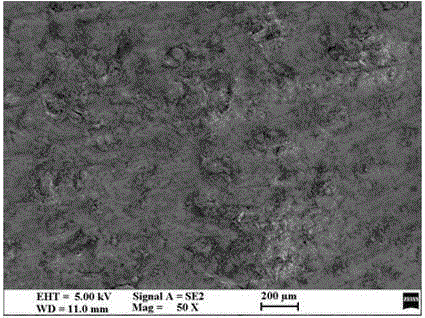

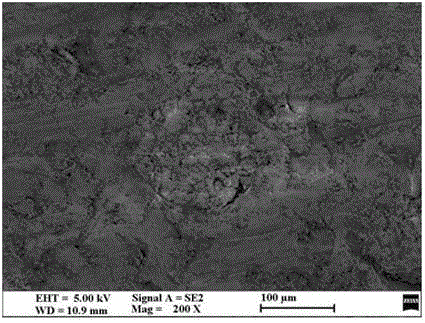

[0019] After adding water to the polymer clay to adjust and harden, the cross-sectional structure was observed by scanning electron microscope. figure 1 , figure 2 They are the scanning electron micrographs of the cross-section after the hardening of polymer clay, magnified 50 times and 100 times, respectively. It can be seen from the figure that polyvinyl alcohol and redispersible latex are fully filled in the voids of cement mortar through their excellent fluidity and film-forming properties, so that there are no obvious voids in the cross-section and the compactness is good.

Embodiment 2

[0021] A kind of polymer beneficial clay, its raw materials are PO42.5 ordinary Portland cement 40kg, quartz sand 50kg (fineness 0.5mm), ash calcium powder 10kg (its Ca(OH) 2 The content is 85%), PVA17883kg, redispersible latex powder 3kg.

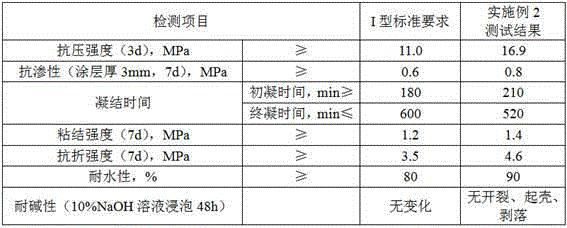

[0022] According to the implementation standard (Type I) of "DB35 / 516-2005 Yijiao Clay" issued by Fujian Provincial Bureau of Quality and Technical Supervision, the test data is shown in Table 1.

[0023] Table 1 Test results

[0024]

[0025] It can be seen from the results in Table 1 that the performance data of the polymer cement in this example is better than the relevant standards, indicating that it is suitable for waterproofing and pasting of moisture-proof layers and veneer panels with waterproof requirements, and veneer panels.

Embodiment 3

[0027] A kind of polymer beneficial clay, its raw materials are PO42.5 ordinary portland cement 30kg, quartz sand 40kg (fineness 0.8mm), ash calcium powder 15kg (its Ca(OH) 2 The content is 87%), PVA20884kg, redispersible latex powder 4kg.

[0028] According to the implementation standard (Type II) of "DB35 / 516-2005 Yijiao Clay" issued by Fujian Provincial Bureau of Quality and Technical Supervision, the test data is shown in Table 2.

[0029] Table 2 Test results

[0030]

[0031] It can be seen from the results in Table 2 that the performance data of the polymer cement in this example is better than the relevant standards, indicating that it is suitable for waterproofing and impermeability in various construction and facility projects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com