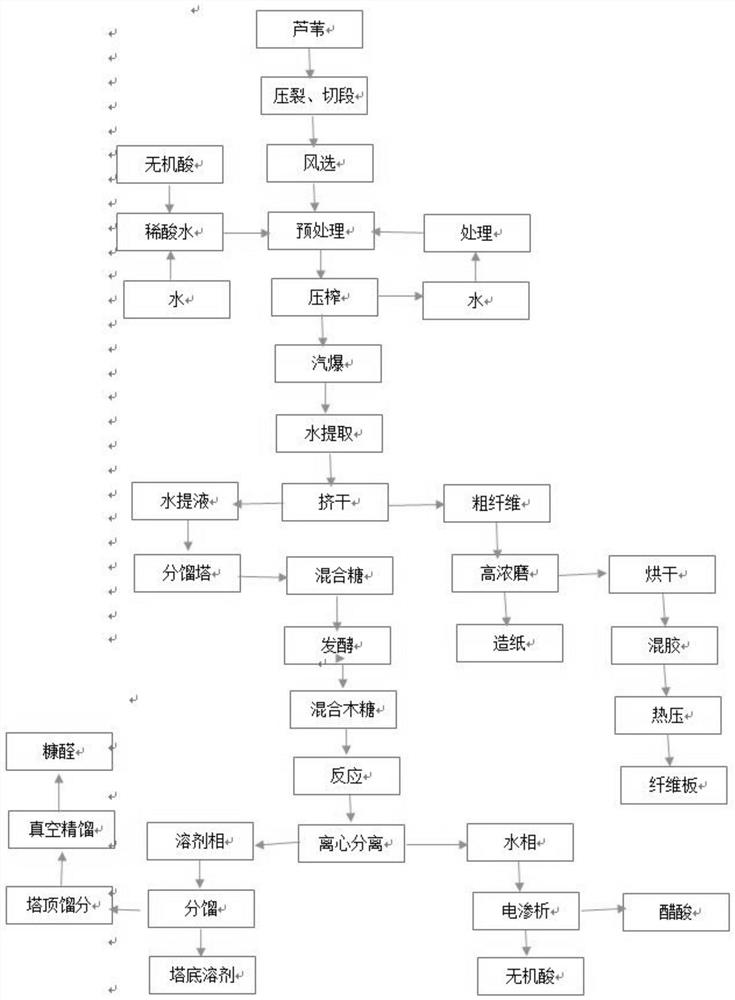

A method for extracting xylose from reed steam explosion to prepare furfural co-production fiberboard

A fiberboard and reed technology, applied in the field of plant extraction, can solve the problems of uneven distribution of laccase enzyme activity, long microbial growth cycle, low production efficiency of pressing plate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

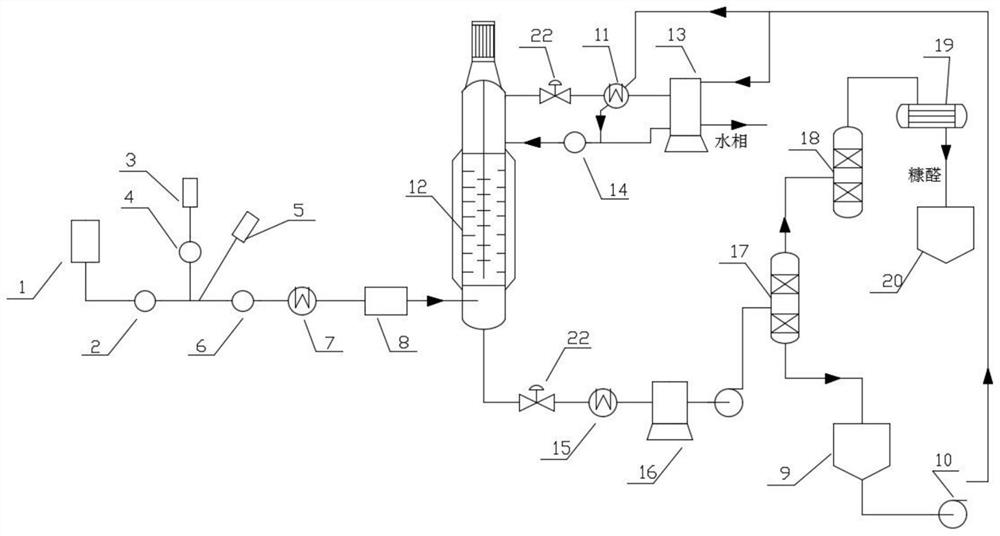

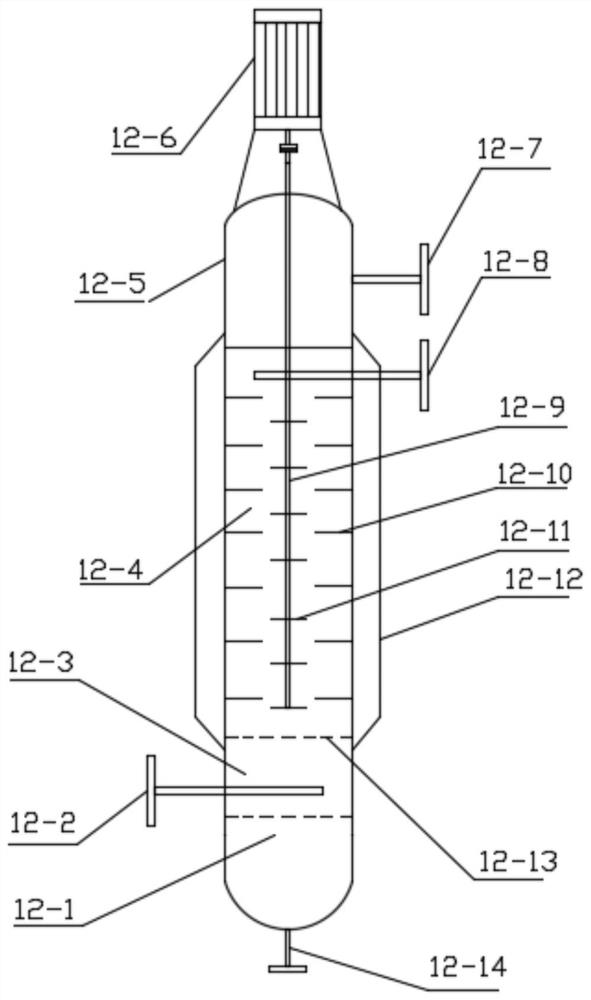

Method used

Image

Examples

Embodiment 1

[0077] A method of preparing xylose prepared by reed steam explosion, including the following steps:

[0078] 1) Raw reed (40 wt% or fresh reed) is fractured, cut into section, length 20-40mm;

[0079] 2) Through the wind conveyance, simultaneously separating impurities such as leaves, flowers and flute membranes, that is, the auto-explosive raw material;

[0080] 3) In the above-mentioned raw material, a concentration of 0.3% by weight of dilute sulfuric acid, solid-liquid ratio is 1: 0.8, mixed with a screw mixer; mixed for 30 minutes, press the press, so that the reed contains 45 wt%. In the steam haller, at 1.6 MPa steam pressure, at 180 ° C temperature, maintained time 120 seconds, instant blasting.

[0081] After the steam explosion, the material was washed with 10 times the mass of 70 ° C for hot water in a continuous washed puller, pressed dehydration to give solid cellulose, lignin, and a small amount of half-fibrin mixture;

[0082] 4) The above water lotion enters the f...

Embodiment 2

[0092] A method of preparing xylose prepared by reed steam explosion, including the following steps:

[0093] 1) Raw reeds are fractured, cut into sections, length 20-40mm;

[0094] 2) Through wind conveyance, simultaneous separation of impurities such as leafs, reed flowers and flute membranes, that is, the auto-burst raw material.

[0095] 3) Dilute sulfuric acid having a concentration of 0.3% (wt / wt) in the above-described steak, solid-liquid ratio 1: 0.8, mixed with a mixer, and the mixer may be a screw type or a roller type. Maintained for 30 minutes, performing press, so that the reed contains 45% by weight. The steam burster was sent in a 1.6 MPa steam pressure, at a temperature of 180 ° C, maintained time 120 seconds, instant blasting.

[0096] After the oil explosion, the material was washed with 10 times in a continuous washed puller, pressed by dehydration, to give solid cellulose, lignin, and a small amount of half-fibrin mixture.

[0097] 4) The above water lotion e...

Embodiment 3

[0107] Reeds are not treated with auto-explosion, and the fiberboard is produced according to conventional methods.

[0108] Approach Furfural yield% Surface adhesive strength / MPA Internal binding strength / MPA Static intensity / MPA Example 1 70 1.6 0.6 27 Example 2 78 1.67 0.58 28 Example 3 —— 1.13 0.40 19

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com