Gypsum tailing mine gelled material and preparation process thereof

A cementitious material and gypsum technology, applied in the field of building materials, can solve the problems of frosting, crystal structure damage, and poor structural stability of hardened bodies, etc., and achieve the effects of simple production process, moderate setting time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

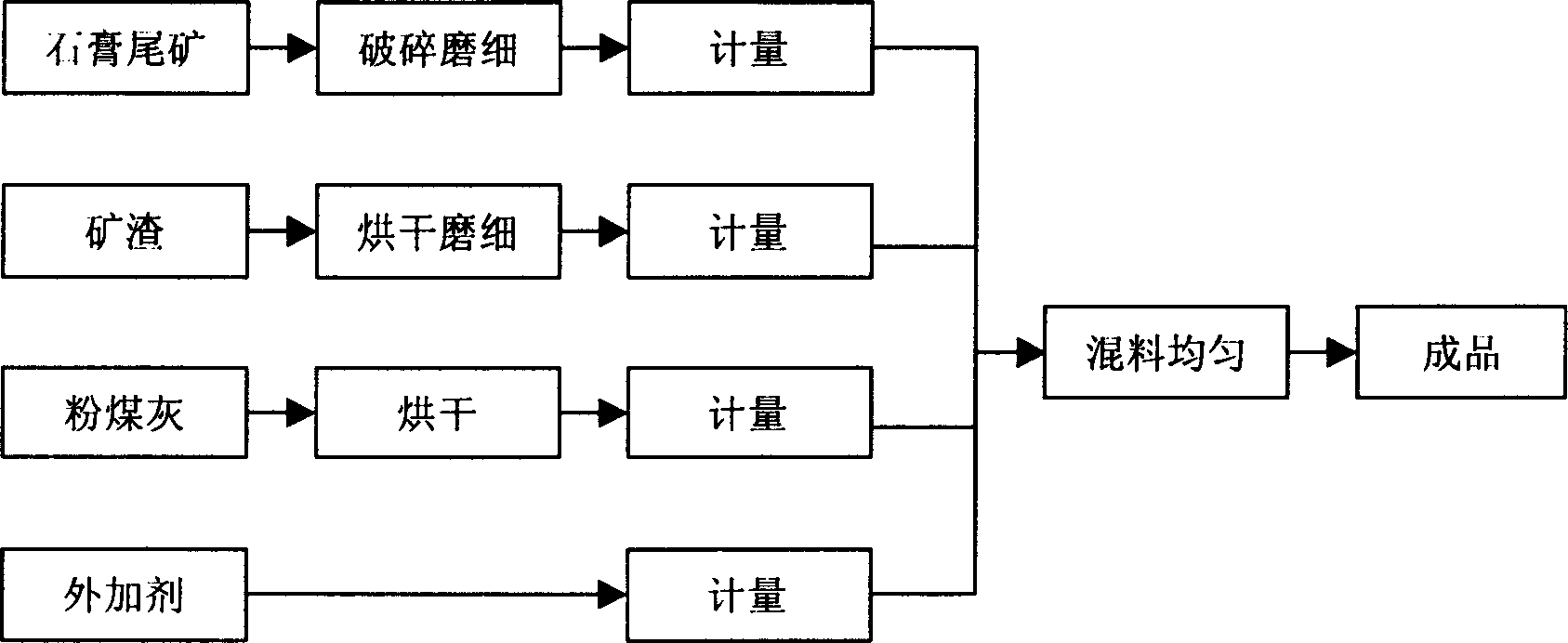

[0025] Such as figure 1 Shown, the preparation method of gypsum tailings cementitious material, it comprises the following steps: 1). The preparation of gypsum tailings powder: the gypsum tailings is crushed to a particle size of less than 10mm, then ground to 0.08mm square hole sieve 15% fine powder for later use; 2). Preparation of slag powder: drying and grinding the water-quenched slag discharged from iron and steel enterprises until the specific surface area is 4001-8000cm 2 / g standby; 3). With the mass ratio of 60% gypsum tailings powder, mass ratio of 30% ground slag powder, mass ratio of 10% dry base fly ash; externally mixed with the gypsum tailings powder 1% activator (quicklime) and 1.5% early strength agent (finely ground alum stone powder) of 1% slag powder and fly ash quality are mixed evenly with a mixer, and the package can leave the factory. When in use, it can be used by mixing according to the water-cement ratio of 0.2-0.3 or mixing 20%-30% of the aggregat...

Embodiment 2

[0027] The preparation method of gypsum tailings cementitious material comprises the following steps: 1). The preparation of gypsum tailings powder: the gypsum tailings are crushed to a particle size of less than 10mm, and then ground to a 0.08mm square hole sieve with a sieve residue of 15 % fine powder for subsequent use; 2). Preparation of slag powder: drying and grinding the water-quenched slag until the specific surface area is greater than 4000cm 2 / g standby; 3). With the mass ratio of 70% gypsum tailings powder, mass ratio of 20% finely ground slag powder, mass ratio of 10% dry base fly ash, externally mixed with the gypsum tailings powder 0.8% activator (quick lime) and 1.3% early strength agent (calcined alunite, ground into powder) of 0.8% slag powder and fly ash quality are mixed evenly with a mixer, and the package can leave the factory. When in use, it can be used by mixing according to the water-cement ratio of 0.2-0.3 or mixing 20%-30% of the aggregate of the p...

Embodiment 3

[0029] A preparation method for gypsum tailings cementitious material, which comprises the following steps: 1). Preparation of gypsum tailings powder: crushing gypsum tailings to a particle size of less than 10mm, and then grinding to a 0.08mm square hole sieve with a sieve residue of 15 % fine powder for subsequent use; 2). Preparation of slag powder: drying and grinding the phosphorus slag until the specific surface area is greater than 4000cm 2 / g for standby; 3). The mass ratio is 60% gypsum tailings powder, the mass ratio is 30% ground slag powder, and the mass ratio is 10% dry base fly ash, and the gypsum tailings powder is mixed with the 1.2% activator (slaked lime) and 1.7% early strength agent (alum powder) of 1.2% slag powder and fly ash quality are mixed evenly with a mixer, and the packaging can leave the factory. When in use, it can be used by mixing according to the water-cement ratio of 0.2-0.3 or mixing 20%-30% of the aggregate of the product quality of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com