Silk fibroin/calcium phosphate bone cement composite material and preparation method thereof

A technology of calcium phosphate bone cement and silk fibroin, which is applied in the field of medical biological materials and preparation thereof, can solve the problems that affect the application of silk fibroin, the fibers are not easily dispersed uniformly, and have no injectability, etc., so as to improve the preparation working conditions and reduce the cost. , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

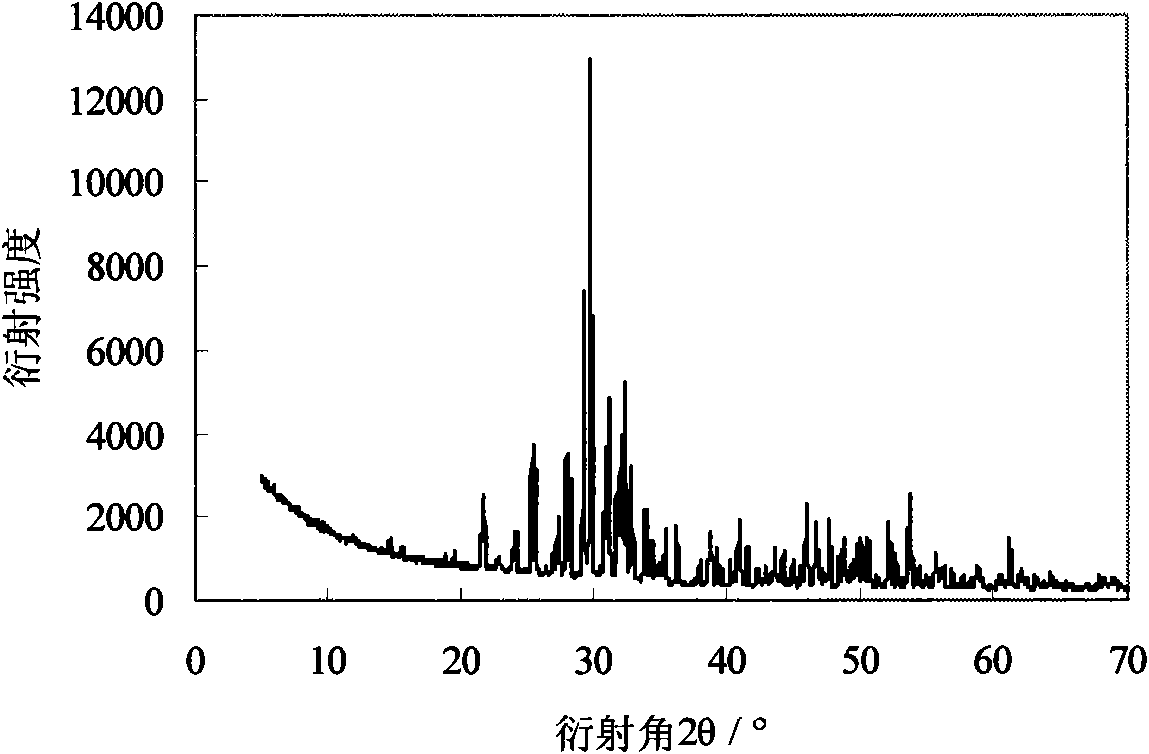

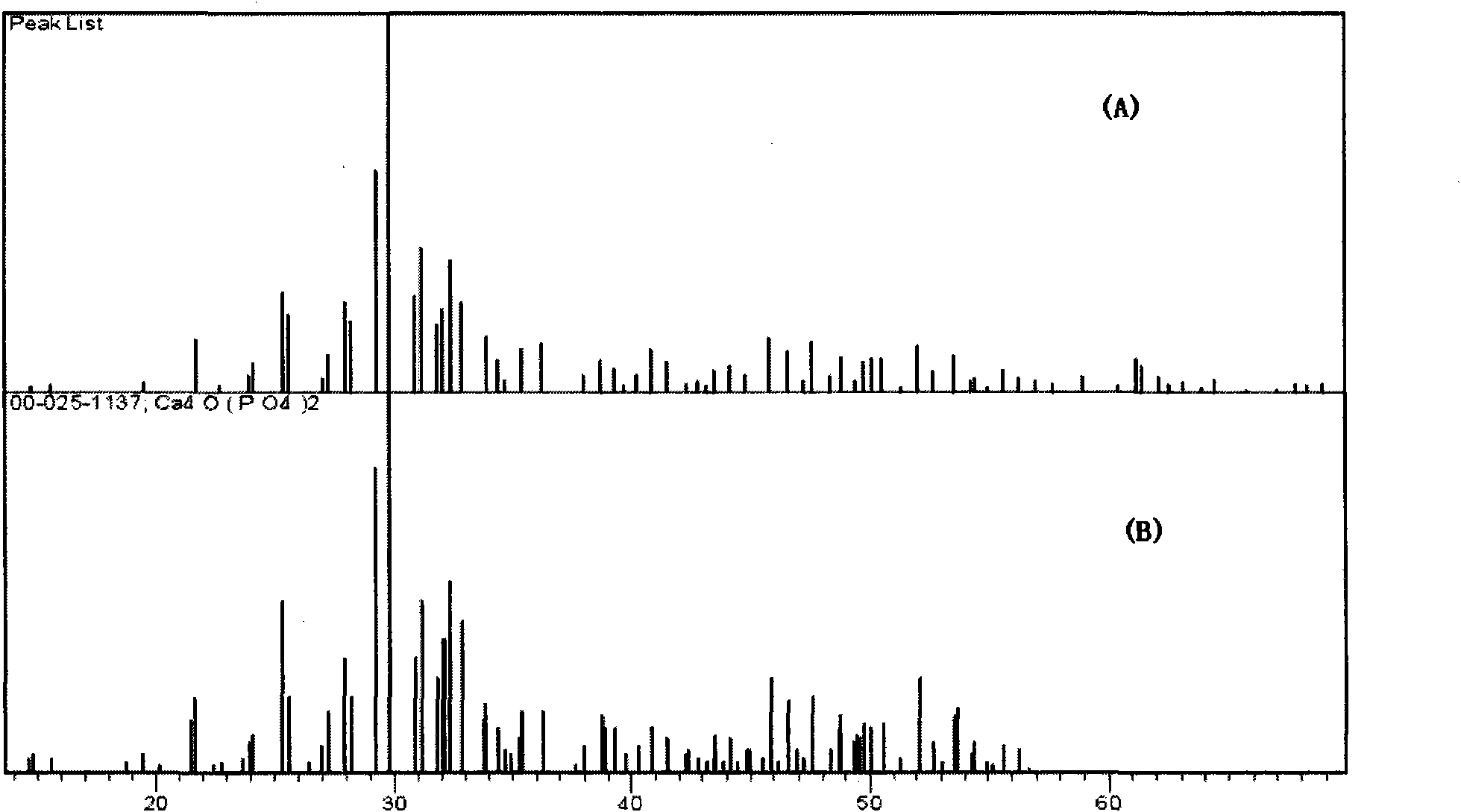

Image

Examples

Embodiment 1

[0022] The preparation steps of the silk fibroin / calcium phosphate bone cement composite material provided by the present embodiment are as follows:

[0023] (1) Preparation of Tetracalcium Phosphate

[0024] Will (NH 4 ) 2 HPO 4 The solution is added dropwise to the Ca(NO 3 ) 2 4H 2 In the O solution, the pH value is kept above 9 during the dropwise addition. After the dropwise addition, continue to stir the reaction for 3 hours, and let it settle for 24 hours. According to the ratio of the Ca / P molar ratio of the entire system to 2.0, add dropwise to the above suspension at the same time. Ca(NO 3 ) 2 4H 2 O solution and (NH 4 ) 2 CO 3 After the dropwise addition of the solution, the aging reaction was continued for 24 hours and then filtered, and the filter cake was dried in an oven at 110° C. for 12 hours. Place the tetracalcium phosphate precursor synthesized by the above liquid phase reaction method in a high-temperature furnace, raise the temperature to 1500°C ...

Embodiment 2

[0034] The non-water-soluble silk fibroin protein powder was prepared according to the technical scheme of Example 1.

[0035] Will (NH 4 ) 2 HPO 4 The solution was added dropwise to Ca(NO 3 ) 2 4H 2 In the O solution, the pH value was kept above 9 during the dropwise addition. After the dropwise addition, continue to stir and react for 3 hours, and let it settle for 22 hours. According to the ratio of the Ca / P molar ratio of the entire system to 2.0, add dropwise to the above suspension at the same time Ca(NO 3 ) 2 4H 2 O solution and (NH 4 ) 2 CO 3 Solution, after the dropwise addition, continue the aging reaction for 22 hours and then filter, put the filter cake in a 110°C oven to dry for 12 hours, then place it in a high-temperature furnace, raise the temperature to 1500°C at a rate of 360°C / h, and keep it for 8 hours. Into nitrogen gas and quickly cooled to 1300°C and taken out, cooled to 100°C in air, then placed in a dry environment and cooled to room tempera...

Embodiment 3

[0039] The non-water-soluble silk fibroin protein powder was prepared according to the technical scheme of Example 1.

[0040] Will (NH 4 ) 2 HPO 4 The solution was added dropwise to Ca(NO 3 ) 2 4H 2 In the O solution, the pH value was kept above 9 during the dropwise addition. After the dropwise addition, continue to stir and react for 3 hours, and let it settle for 20 hours. According to the ratio of the Ca / P molar ratio of the entire system to 2.0, dropwise add Ca(NO 3 ) 2 4H 2 O solution and (NH 4 ) 2 CO 3 Solution, after the dropwise addition, continue the aging reaction for 24 hours and then filter, put the filter cake in a 110°C oven to dry for 12 hours, then place it in a high-temperature furnace, raise the temperature to 1500°C at a rate of 360°C / h, and keep it for 8 hours. Into nitrogen gas and quickly cooled to 1300°C and taken out, cooled to 102°C in air, then placed in a dry environment and cooled to normal temperature to obtain tetracalcium phosphate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com