Polymer emulsified asphalt ultrathin surface sealing layer material, and preparation method and application thereof

A technology of emulsified asphalt and layer materials, which is applied in the direction of building insulation materials, building structures, building components, etc., can solve the problem of difficulty in meeting the preventive maintenance requirements of asphalt pavement, low bonding strength between cementitious material and base surface, wear resistance and Problems such as poor skid resistance, etc., to achieve the effect of being suitable for industrial scale production, good embedding effect, and high Marshall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

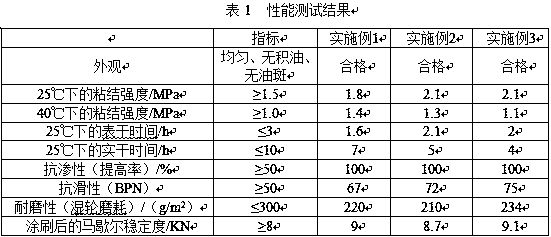

Examples

Embodiment 1

[0061]The sealing layer material is composed of: 45 parts of glycidyl ether epoxy-modified acrylic emulsion grafted modified acrylic acid, 35 parts of 70# emulsified asphalt, β,β'-dimethylaminoethoxy-4,4,5 , 3 parts of 5-tetramethyl-1,3,2-dioxaborolane, 4 parts of pure polyester matting resin RB608, 4 parts of polysiloxane derivatives, 3 parts of aliphatic amide dispersant, alkane 12 parts of phenol polyoxyethylene ether TX-1010, 75 parts of quartz sand with a particle size of 70-110 mesh and 35 parts of kaolin; all in parts by mass.

[0062] The preparation method of described sealing layer material, concrete steps are:

[0063] Heat 70# emulsified asphalt and glycidyl ether-based epoxy-modified acrylic emulsion graft-modified acrylic acid to 50°C, mix, then shear at a shear rate of 2500 rpm, and then add β,β'-di Methylaminoethoxy-4,4,5,5-tetramethyl-1,3,2-dioxaborolane, cut for 5 minutes, then add pure polyester matting resin RB608, polysiloxane derivative material, polyoc...

Embodiment 2

[0066] The sealing layer material is composed of: 50 parts of glycidyl ether epoxy modified acrylic emulsion grafted modified acrylic acid, 38 parts of SBS modified 70# emulsified asphalt, β,β'-dimethylaminoethoxy-4, 5 parts of 4,5,5-tetramethyl-1,3,2-dioxaborolane, 3 parts of pure polyester matting resin RB608, 5 parts of polysiloxane derivatives, 4 parts of polyoctylamide, alkanes 18 parts of phenol polyoxyethylene ether NP-10, 70 parts of corundum with a particle size of 70-110 mesh and 45 parts of barium sulfate; all in parts by mass.

[0067] The preparation method of described sealing layer material, concrete steps are:

[0068] Heat SBS-modified 70# emulsified asphalt and glycidyl ether epoxy-modified acrylic emulsion graft-modified acrylic acid to 55°C, mix, and then shear at a shear rate of 2800 rpm, and then add β, β '-Dimethylaminoethoxy-4,4,5,5-tetramethyl-1,3,2-dioxaborolane, cut for 8 minutes, then add pure polyester matting resin RB608, polysil Oxyalkylene der...

Embodiment 3

[0071] The sealing layer material is composed of: 60 parts of glycidyl ether epoxy-modified acrylic emulsion grafted modified acrylic acid, 40 parts of 70# emulsified asphalt, β,β'-dimethylaminoethoxy-4,4,5 , 8 parts of 5-tetramethyl-1,3,2-dioxaborolane, 5 parts of pure polyester matting resin RB608, 6 parts of polysiloxane derivatives, 5 parts of polyoctylamide, fatty alcohol polyoxygen 22 parts of vinyl ether AEO-9, 80 parts of quartz sand with a particle size of 70-110 meshes and 60 parts of talcum powder; all in parts by mass.

[0072] The preparation method of described sealing layer material, its concrete steps are:

[0073] Heat 70# emulsified asphalt and glycidyl ether epoxy-modified acrylic emulsion graft-modified acrylic acid to 60°C, mix, then shear at a shear rate of 3000 rpm, add β,β'-dimethyl Aminoethoxy-4,4,5,5-tetramethyl-1,3,2-dioxaborolane, cut for 10 min, then add pure polyester matting resin RB608, polysiloxane derivative material, polyoctylamide, fatty a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| impermeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com