Method for carrying out water expelling and powder spray piling composite foundation ground

An operation method and technology of composite foundation, applied in the field of soft soil foundation treatment, can solve problems such as ground cracking, slow drainage speed, low efficiency, etc., achieve major economic and social benefits, accelerate strength growth, and save engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

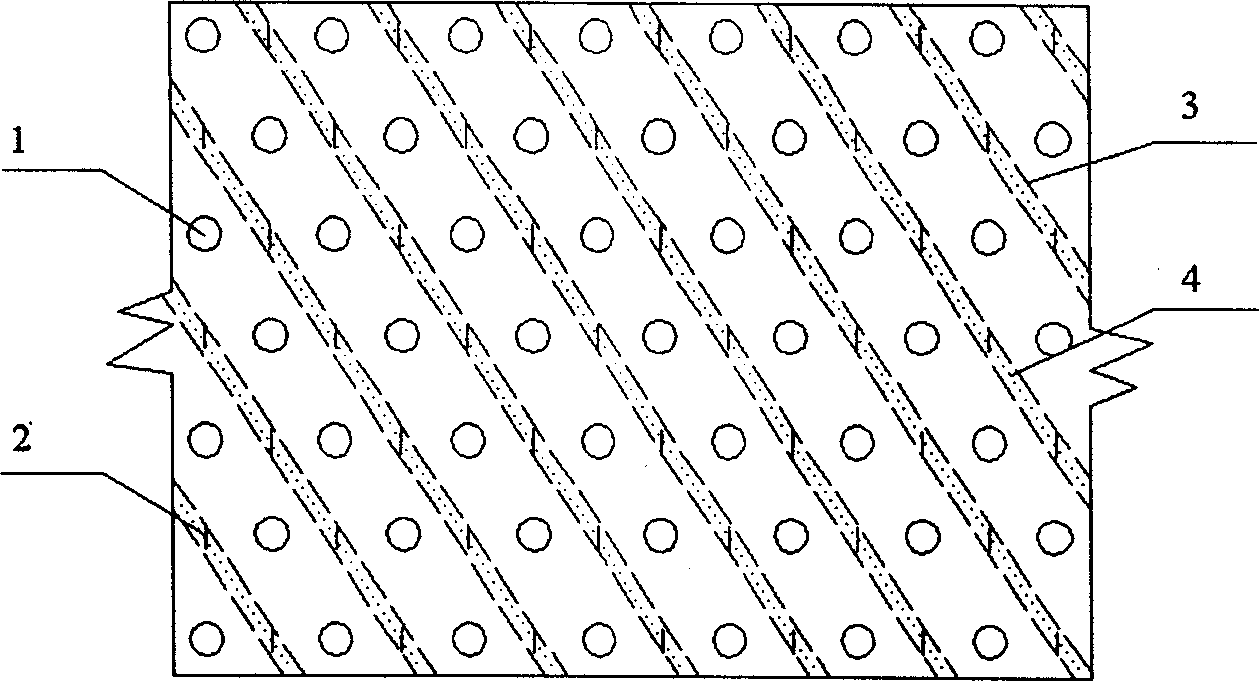

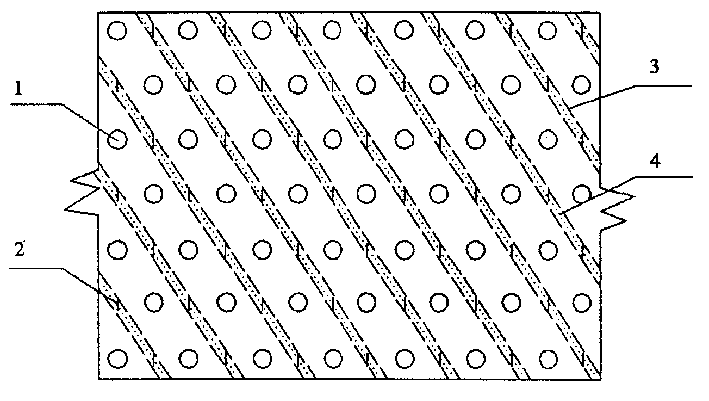

[0030] The invention organically combines two independent soft soil foundation technologies, the drainage method and the powder spraying pile method. Firstly, the drainage board is set in the soft soil foundation to form the drainage and exhaust channel during the construction of the powder spraying pile, and then the powder spraying pile is embedded, and the water in the soft soil is discharged along the drainage board by using the lateral pressure during the construction of the powder spraying pile, and at the same time Through the action of expansion, splitting occurs, causing horizontal cracks in the soft soil, thereby increasing the permeability of the soil around the pile. Under the action of consolidation, the strength of the soil around the pile will increase with time; on the other hand, in the powder spraying During pile construction, due to the drainage and exhaust function of the drainage board, the powder-sprayed pile can be stirred evenly and the powder sprayed ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com