Copper-containing high-strength high-toughness welding rod deposited metal

A technology of deposited metal and high strength, which is applied in the direction of metal processing equipment, welding medium, welding equipment, etc., to achieve the effect of good welding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

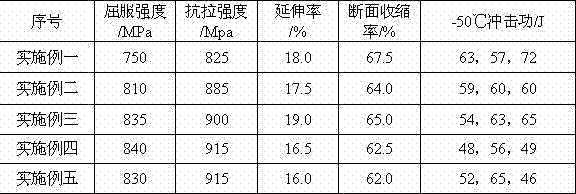

[0024] Welded 10CrNi5MoV steel with electrodes of this deposited metal composition, prepared deposited metal samples, and carried out basic performance tests. The results are listed in Table 1~Table 3. Among them, Table 1 is the welding process parameters of the deposited metal test plate in the embodiment; Table 2 is the chemical composition of the deposited metal in Embodiment 1 to Embodiment 5; Table 3 is the mechanical properties of the deposited metal in Embodiment 1 to Embodiment 5.

[0025] Table 1

[0026] Welding current, A Arc voltage, V Welding speed, cm / min Interpass temperature, ℃ 170±10 24~28 13~17 100±20

[0027] Table 2 The unit is mass percent

[0028] element C Si mn Cr Ni Mo Cu S P Embodiment one 0.030 0.316 0.900 0.832 2.20 0.40 0.70 0.0069 0.017 Embodiment two 0.050 0.264 0.702 0.690 2.85 0.47 0.814 0.0076 0.013 Embodiment three 0.046 0.350 0.830 1.00 2.48 0.60 0.93 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com