GH4169 high-temperature alloy bar and manufacturing method thereof

A technology of GH4169 and superalloy, which is applied in the preparation of the above-mentioned GH4169 superalloy bar and in the field of GH4169 superalloy bar, can solve the problems such as insufficient uniformity of structure, achieve uniform structure, uniform low-magnification structure, and improve uniformity of structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

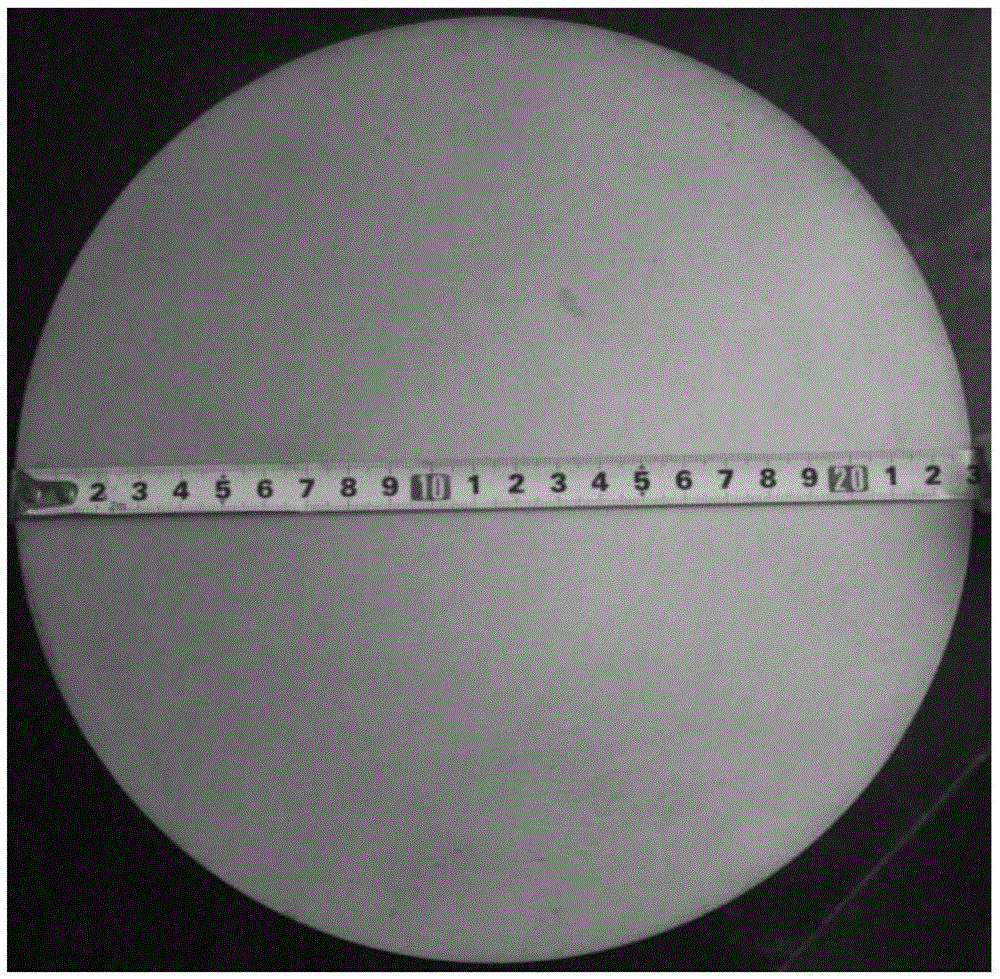

[0036] Preparation of Φ200mm GH4169 superalloy rods:

[0037] Step 1: The size of the billet casting ingot is Ф508mm. The GH4169 ingot that has been homogenized and heat-treated is subjected to one-shot billet forging. The ingot is subjected to two upsetting and one drawing processes on a 4500T fast forging machine. The heating temperature is 1080°C. The deformation amount of thick and elongated is 40%, and the deformation amount of each pass is 25%. After the forging is completed, the surface temperature of the billet is 900°C, and the billet is obtained;

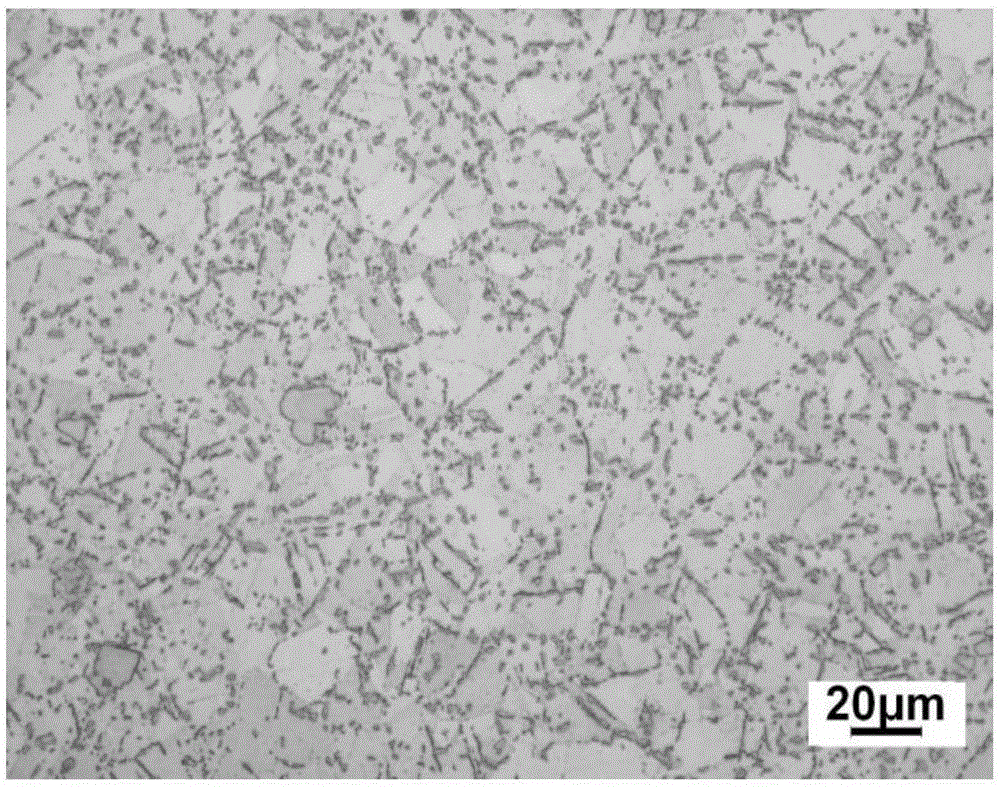

[0038] Step 2: Then carry out the 2nd to 3rd fire forging on the blank obtained in step 1, and alternately upsetting and elongating the blank in the radial and axial directions on the 4500T fast forging machine. The heating temperature is 1050°C, upsetting and The amount of deformation for elongation is 30%, the amount of deformation for each pass is not less than 25%, and the surface temperature of the billet after forgin...

Embodiment 2

[0042] Preparation of Φ250mm GH4169 superalloy rods:

[0043] Step 1: The GH4169 ingot that has been homogenized and heat-treated is subjected to one-shot billet forging, and the ingot is subjected to two upsetting and one drawing processes on a 4500T fast forging machine. The heating temperature is 1110°C, and the deformation of upsetting and elongating is 60%, the amount of deformation per pass is 30%, and the surface temperature of the billet after forging is 950°C, and the billet is made;

[0044] Step 2: Then carry out the 2nd to 3rd fire forging for the billet obtained in step 1, and alternately upsetting and elongating the billet radially and axially on the 4500T fast forging machine. The heating temperature is 1070°C, upsetting and The amount of deformation for elongation is 45%, the amount of deformation for each pass is 30%, and the surface temperature of the billet after forging is 900°C;

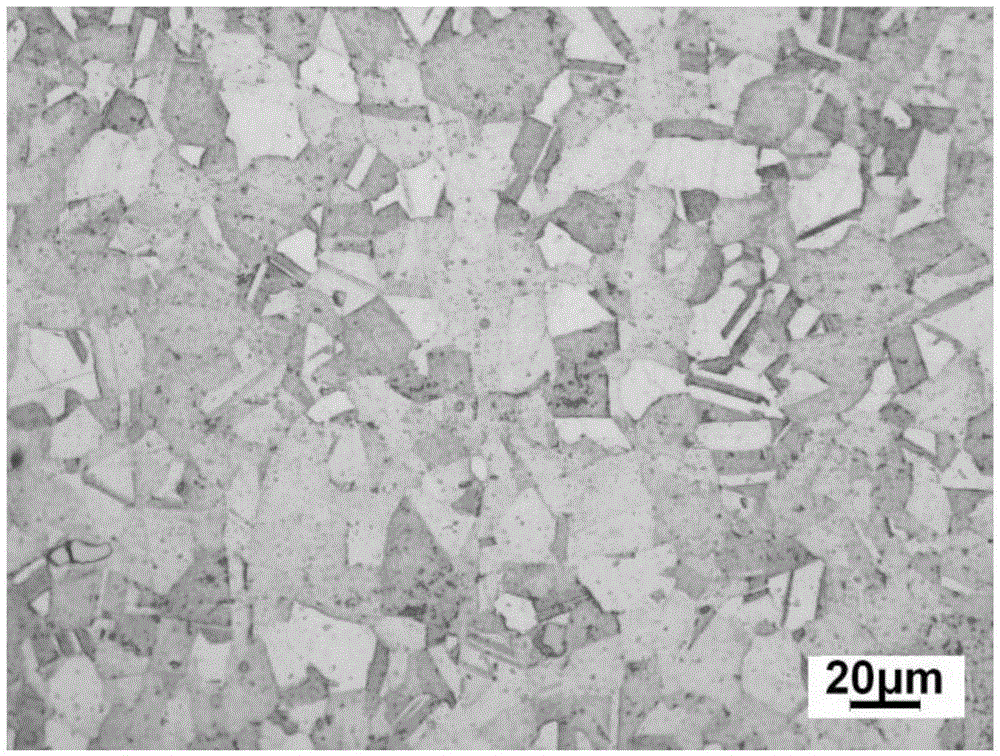

[0045] Step 3: Then carry out the 4th to 5th heat forging of the billet, an...

Embodiment 3

[0048] Preparation of GH4169 superalloy rods of Φ300mm:

[0049] Step 1: The GH4169 ingot that has been subjected to homogenization heat treatment is subjected to one-shot billet forging, and the ingot is subjected to two upsetting and one drawing processes on a 4500T fast forging machine. The heating temperature is 1150°C, and the deformation of upsetting and elongating is 80%, the amount of deformation per pass is 35%, and the surface temperature of the billet after forging is 1000°C, and the billet is made;

[0050] Step 2: Then carry out the 2nd to 3rd fire forging on the blank obtained in step 1, and alternately upsetting and elongating the blank in the radial and axial directions on the 4500T fast forging machine. The heating temperature is 1100°C, upsetting and The amount of deformation for elongation is 60%, the amount of deformation for each pass is 35%, and the surface temperature of the billet after forging is 950°C;

[0051] Step 3: Then the billet is forged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com