Diversified cross-connection control method for plate shape of hot rolling band steel

A control method and technology of hot-rolled strip steel, applied in the direction of contour control, etc., can solve problems such as increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is applied in the 2250mm wide-band hot continuous rolling production line of Taiyuan Iron and Steel Co., Ltd. The shape control equipment adopts CVC+. The maximum rolling pressure of F1--F2 is 50000KN, the maximum rolling pressure of F3--F4 is 45000KN, and the maximum rolling pressure of F5--F7 is 40000KN. The rolling mills are all equipped with cooling water devices, a total of 6 cooling water control equipment in the rolling mills, with a maximum control flow of 160m3 / h. The exit of the finishing mill is equipped with a multifunctional detector and a flatness detector to measure the crown and flatness of the strip respectively.

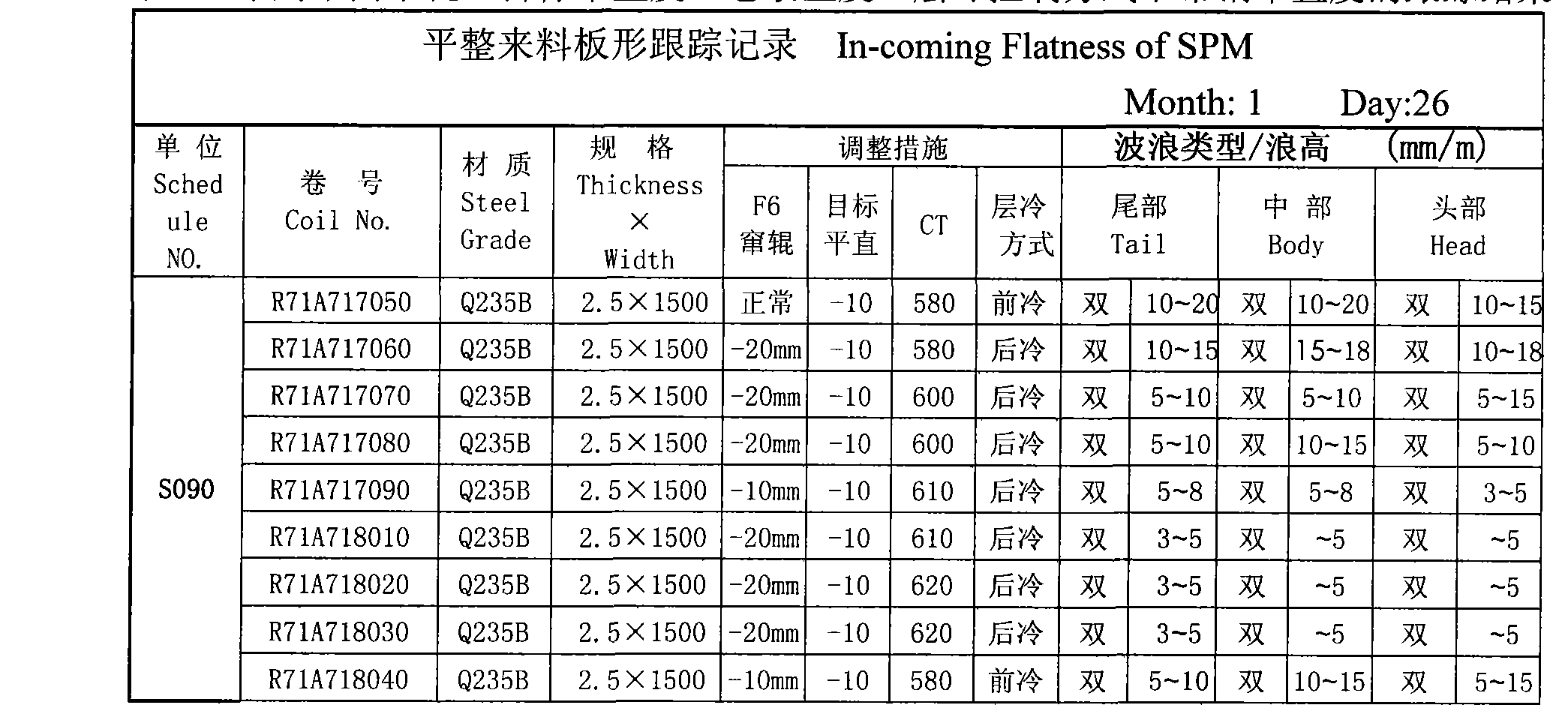

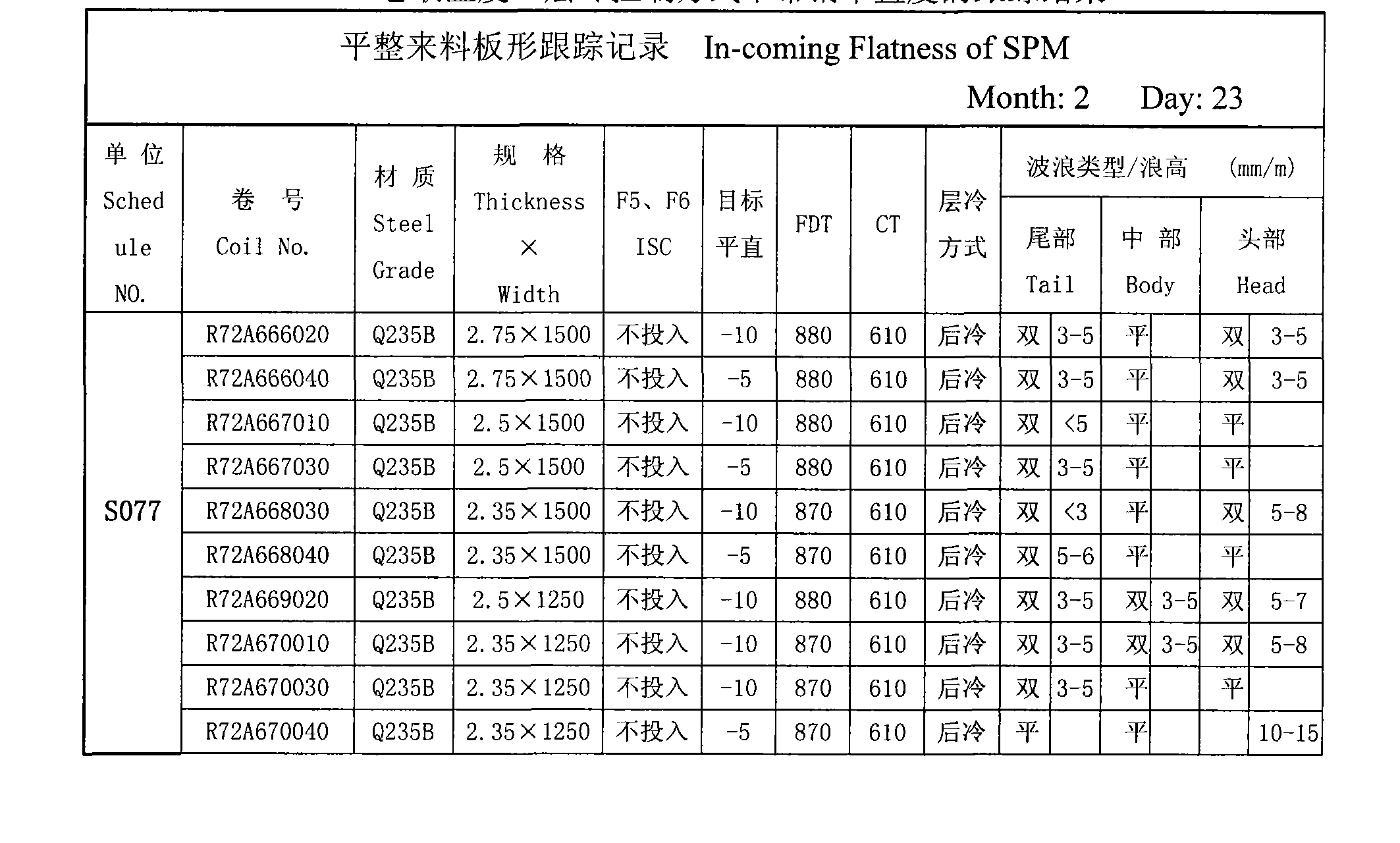

[0022] After the 2250mm hot rolling production line of Taiyuan Iron and Steel Co., Ltd. was put into production, the plate shape of the finished strip steel with a thickness of less than 4mm showed a double-sided wave with a wave height greater than 25mm / m, and the double-sided wave of the finished strip with a thickness of les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com