Patents

Literature

30results about How to "Appearance is rich and varied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

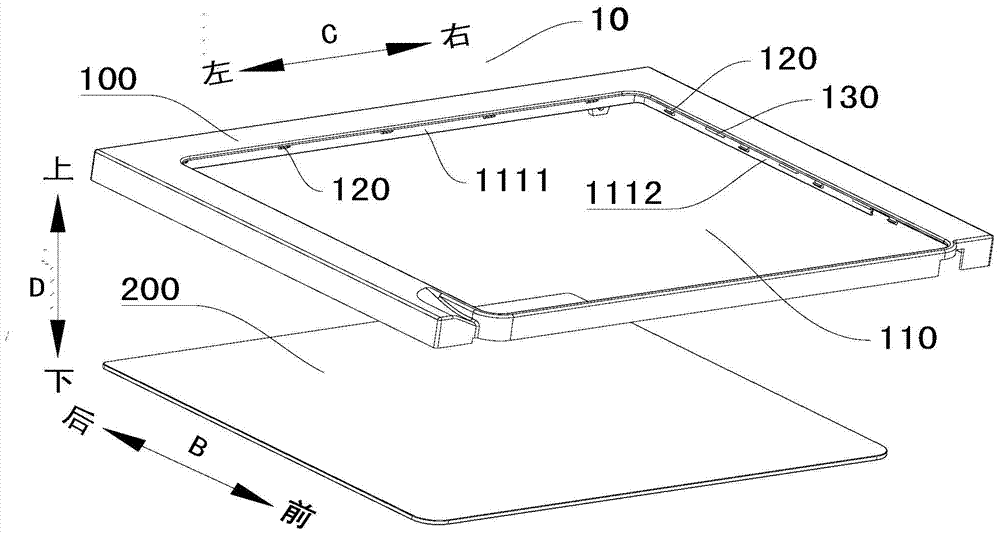

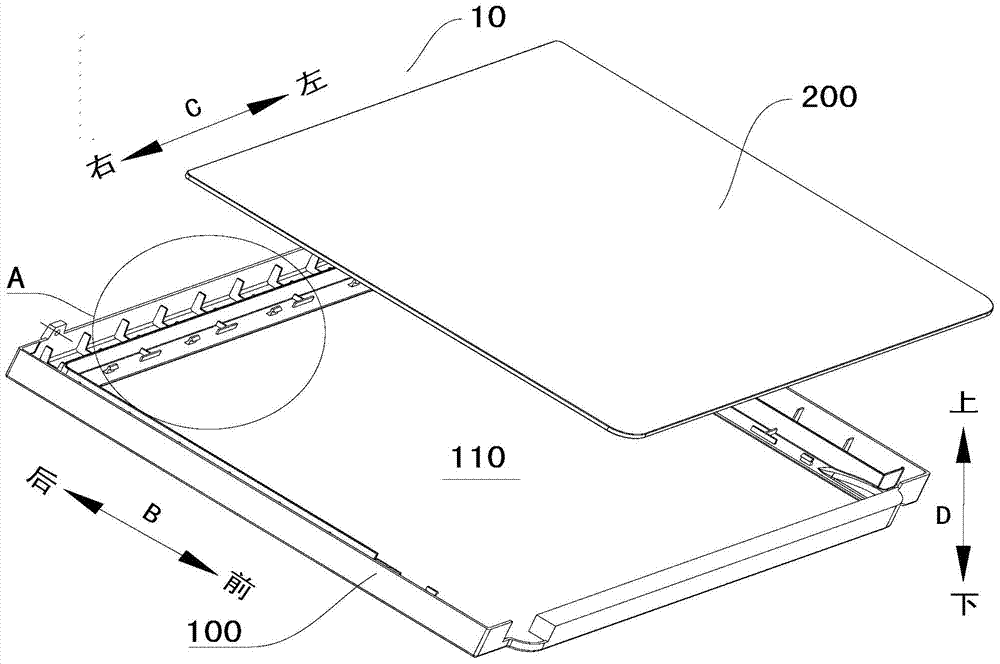

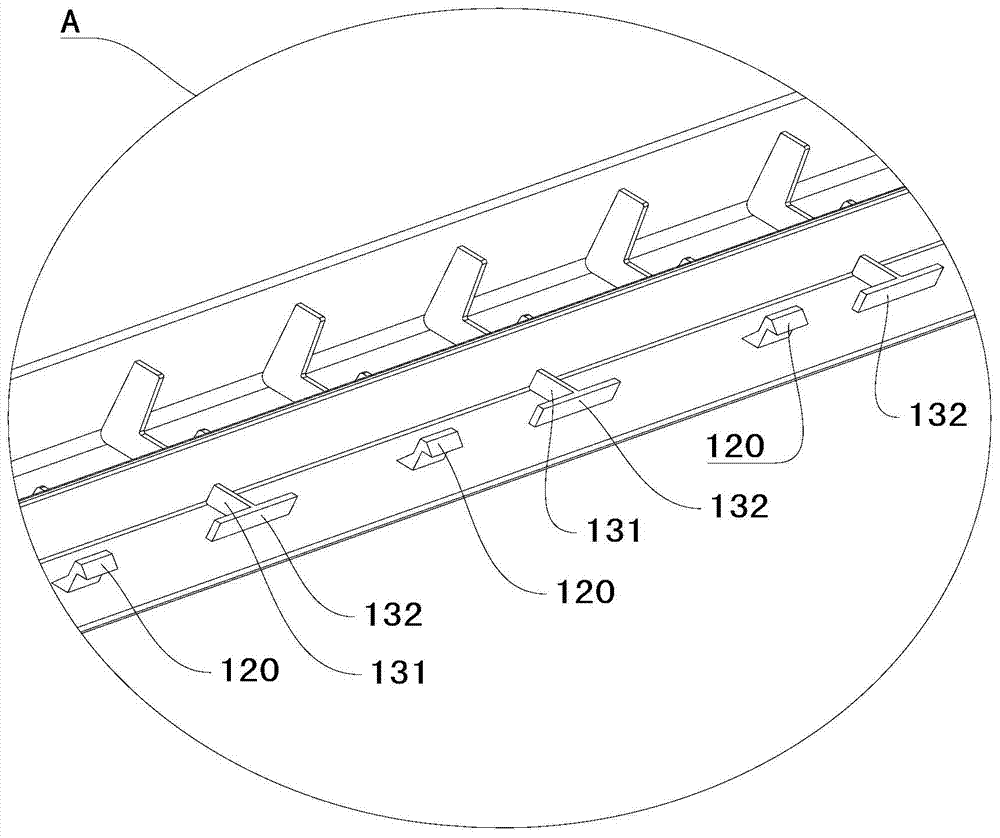

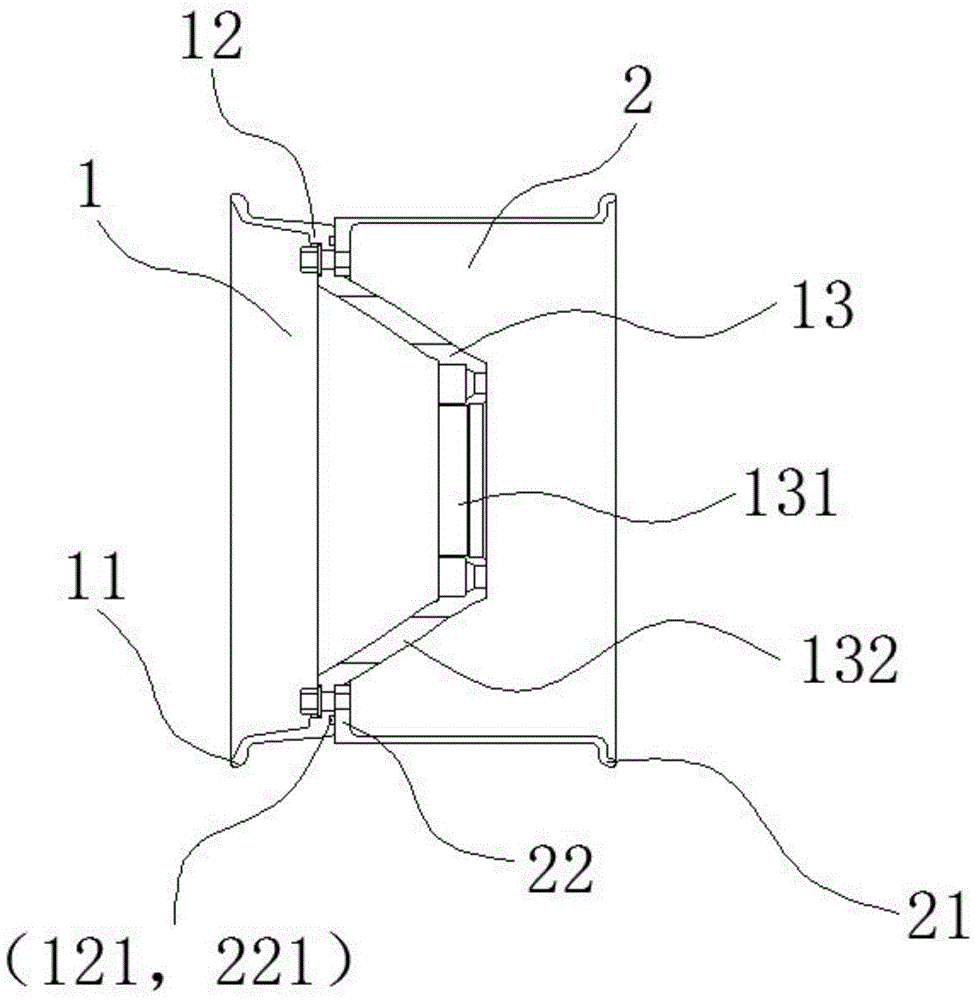

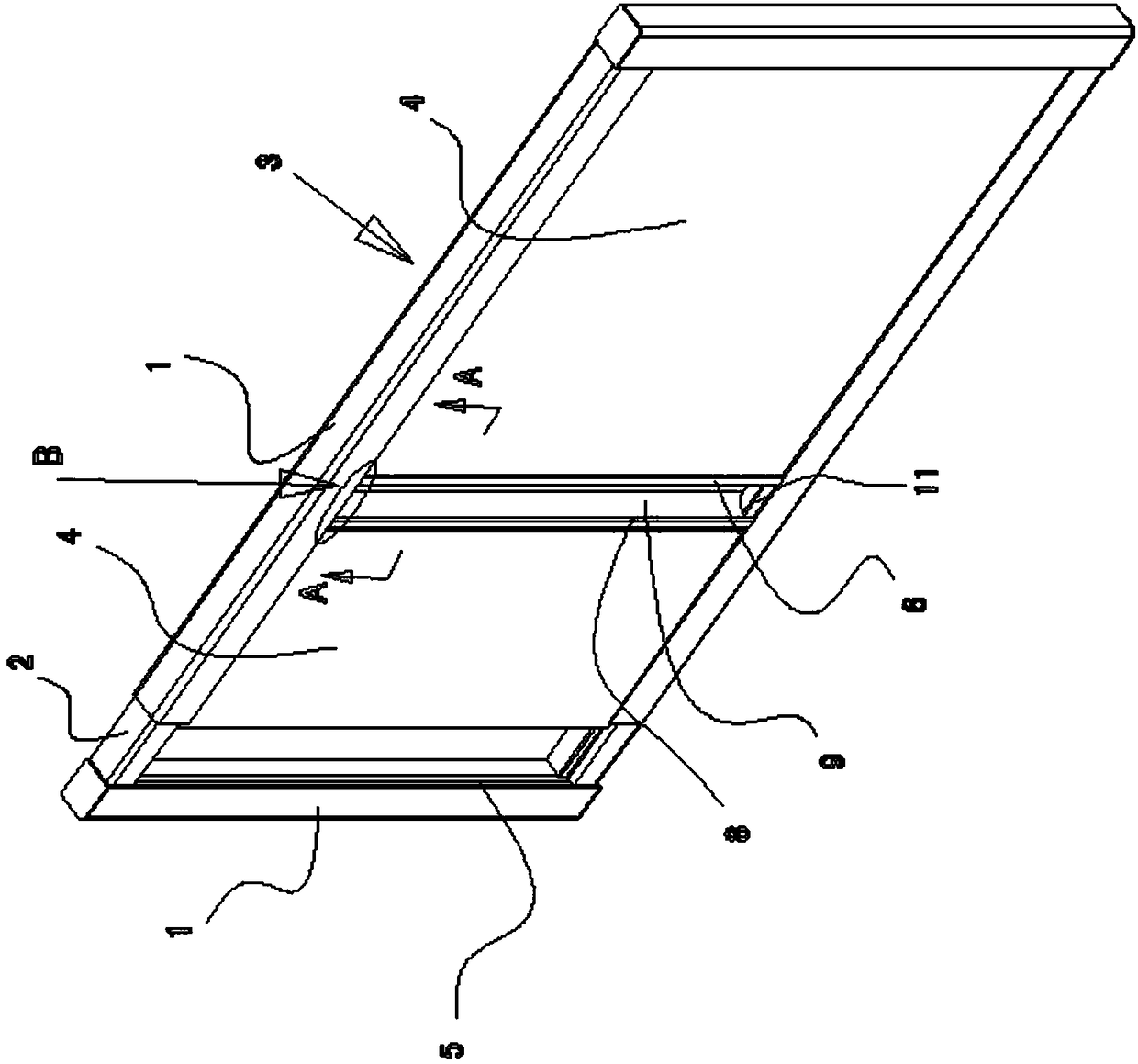

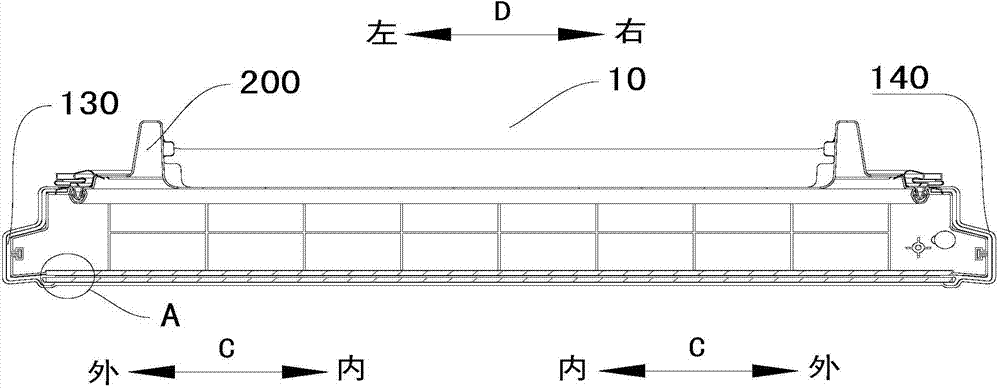

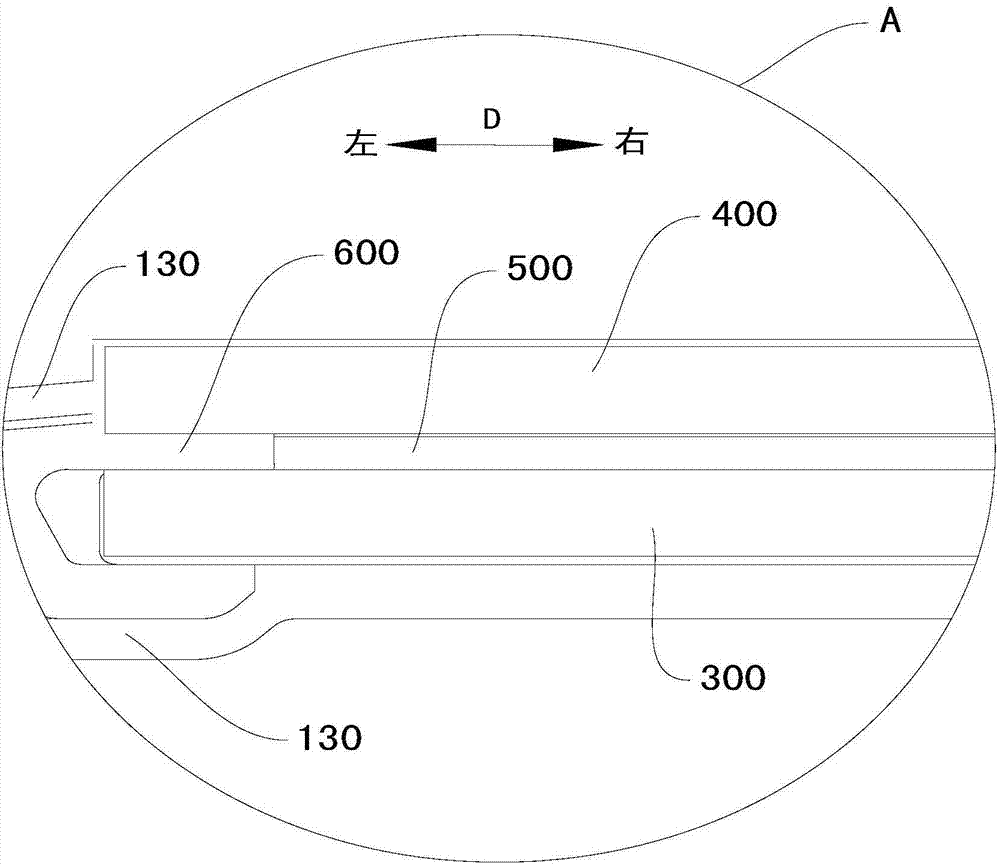

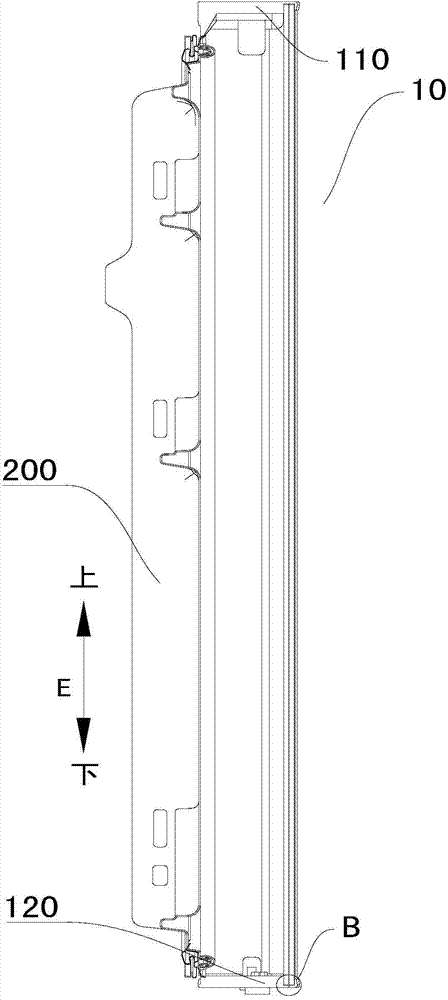

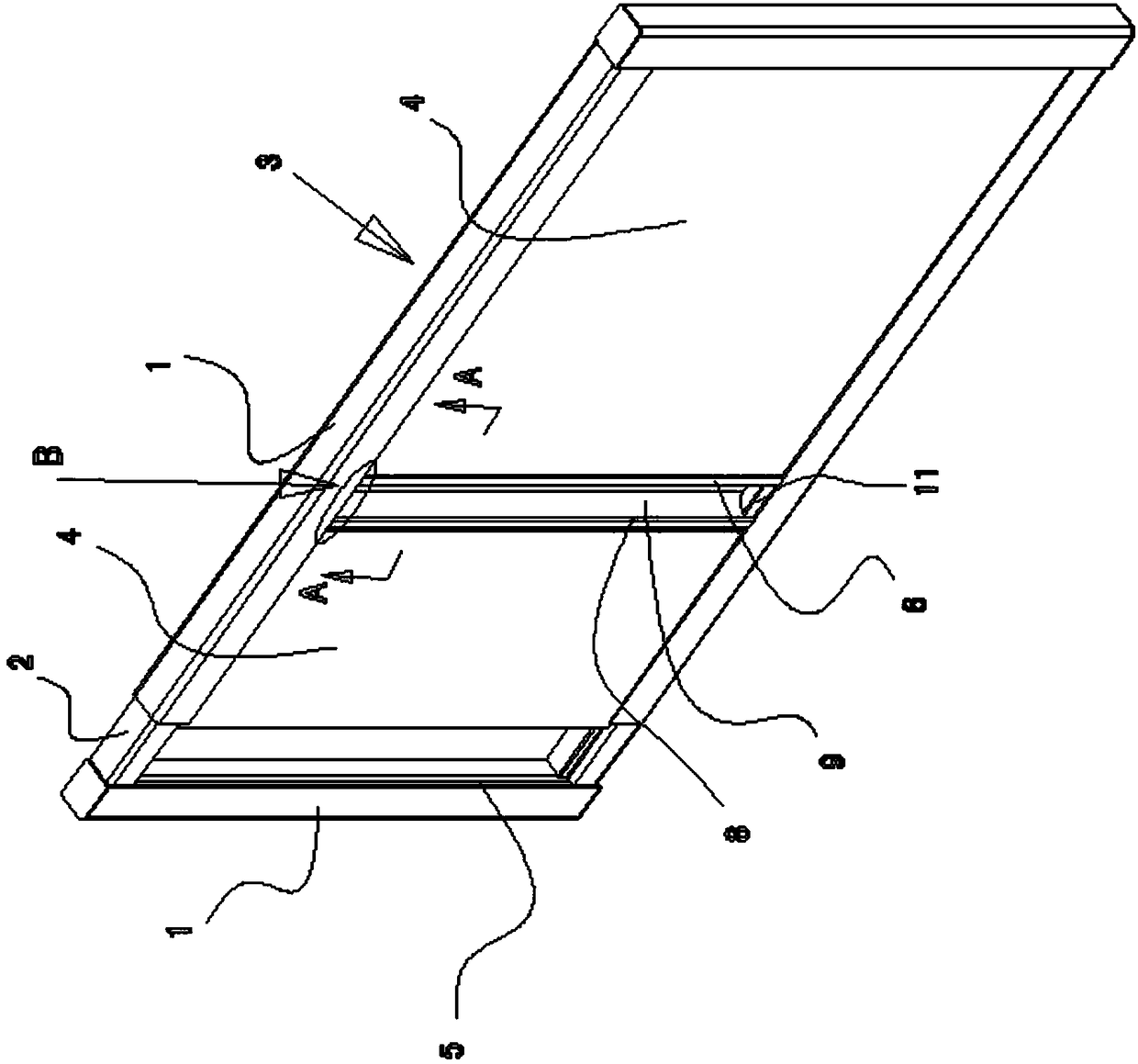

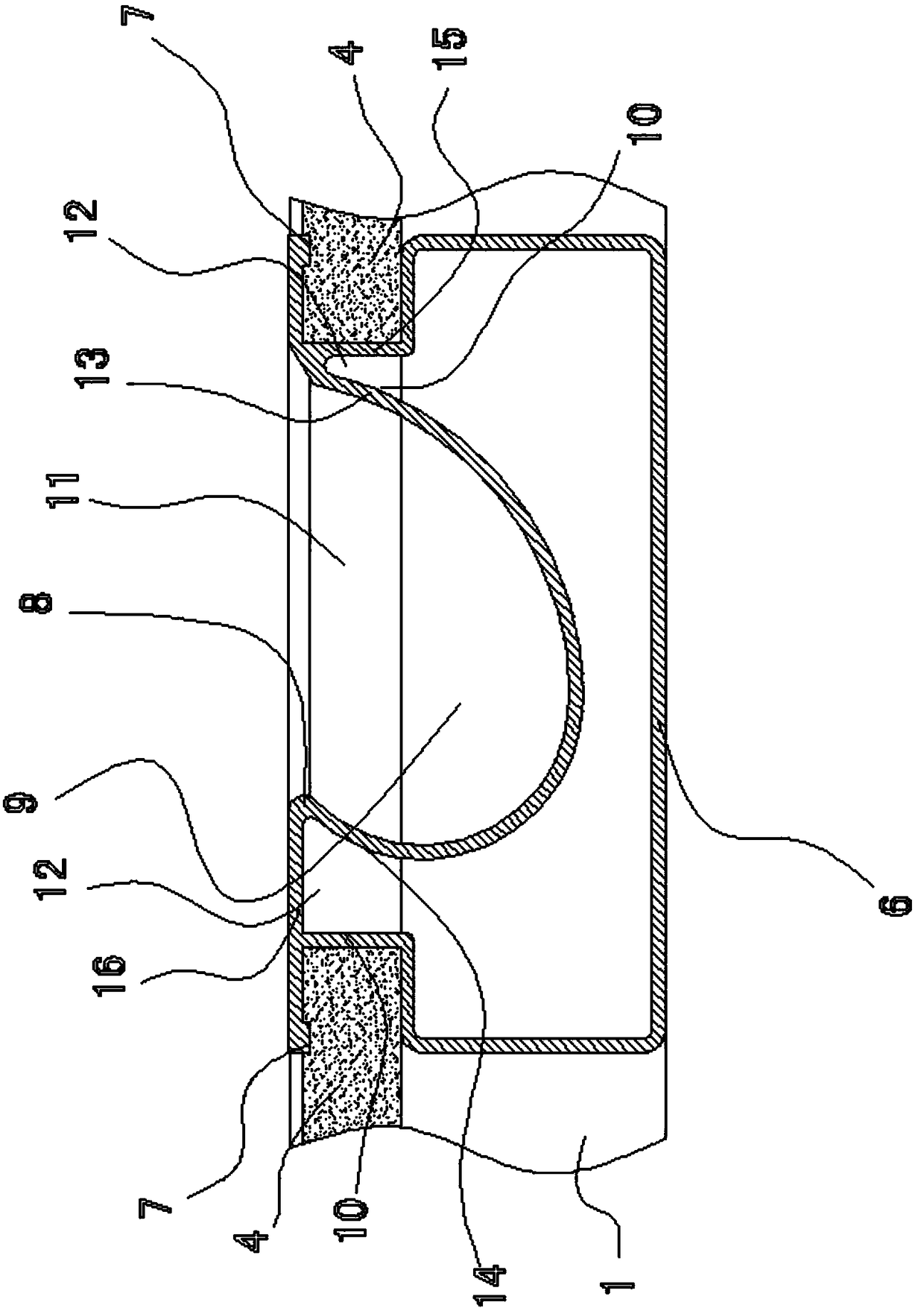

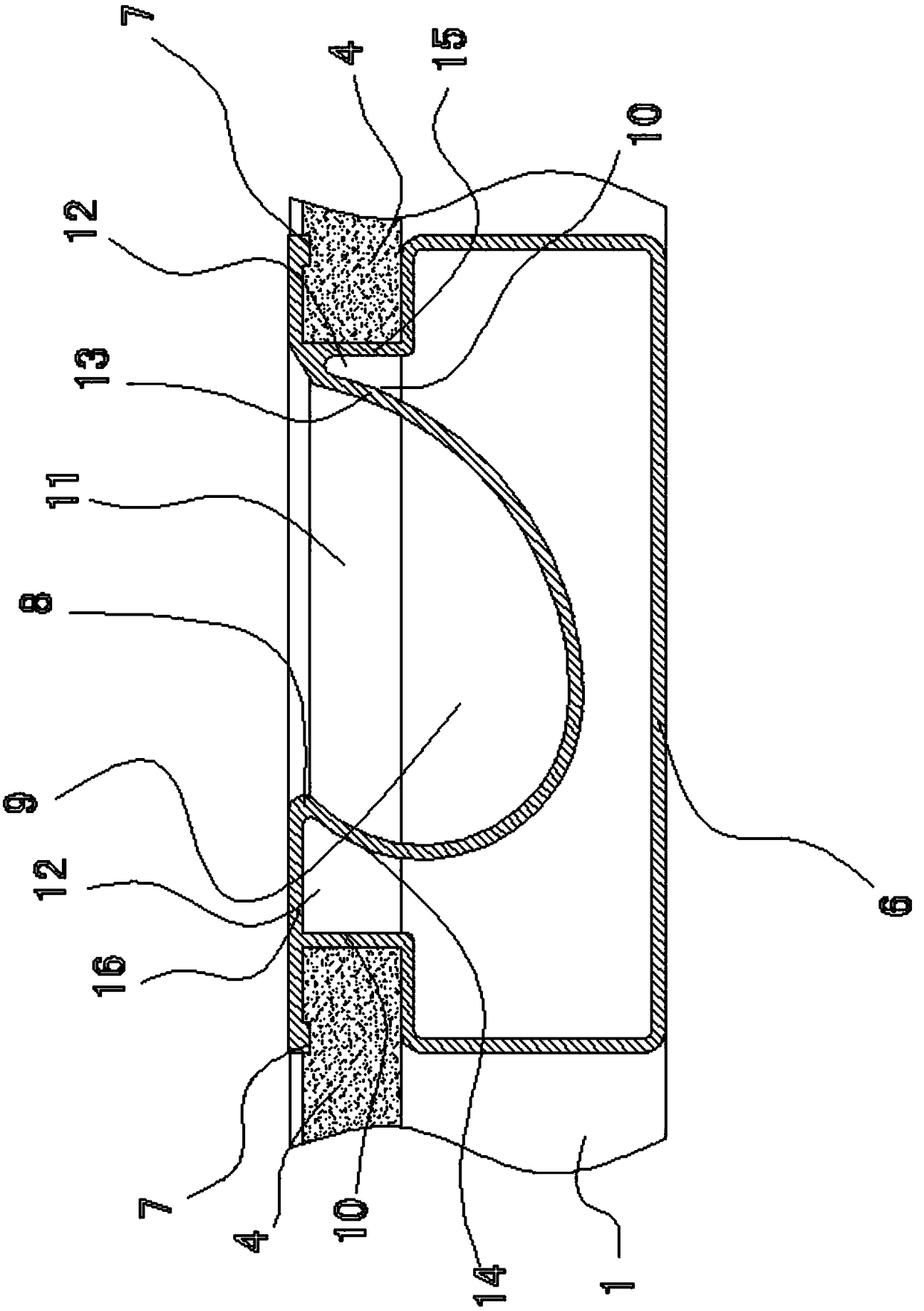

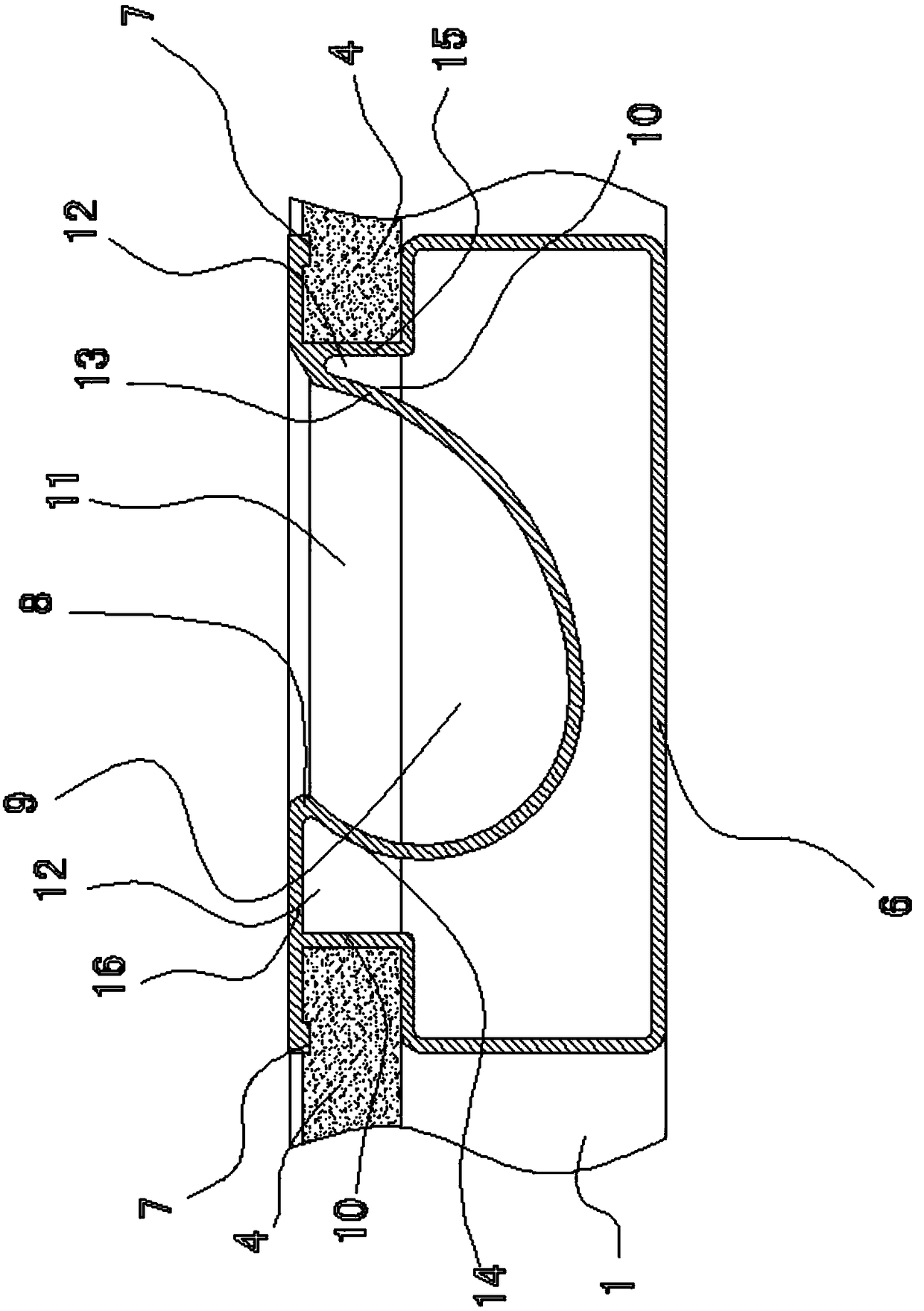

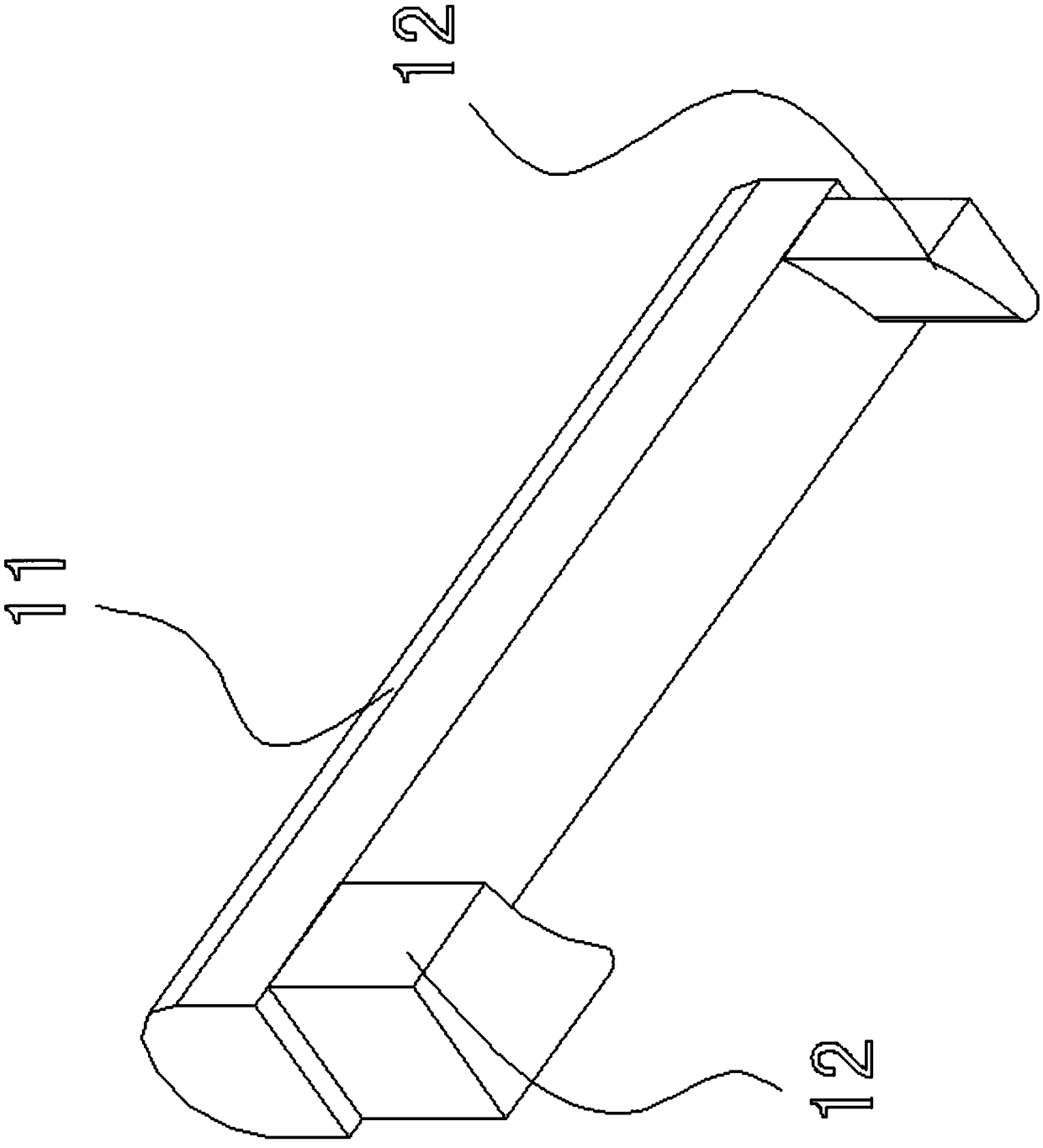

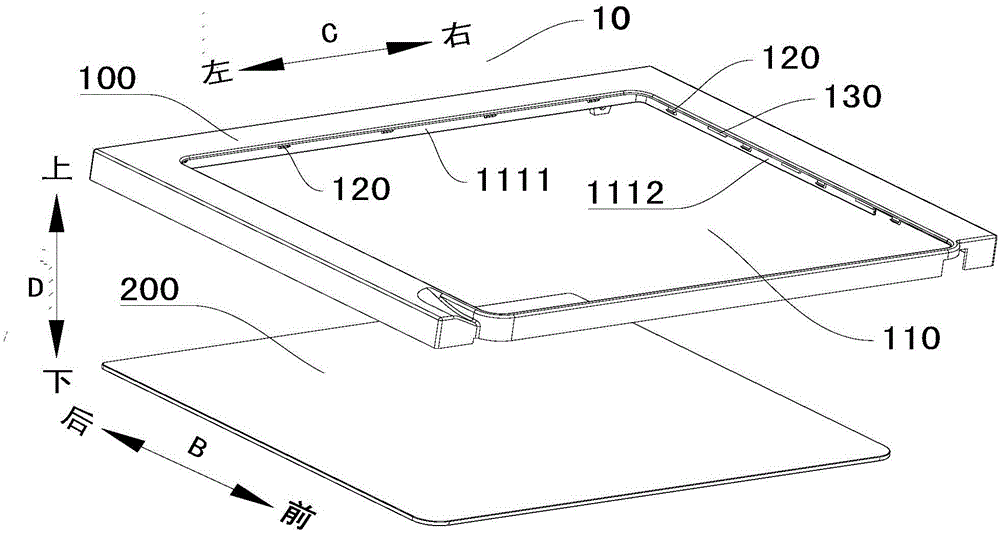

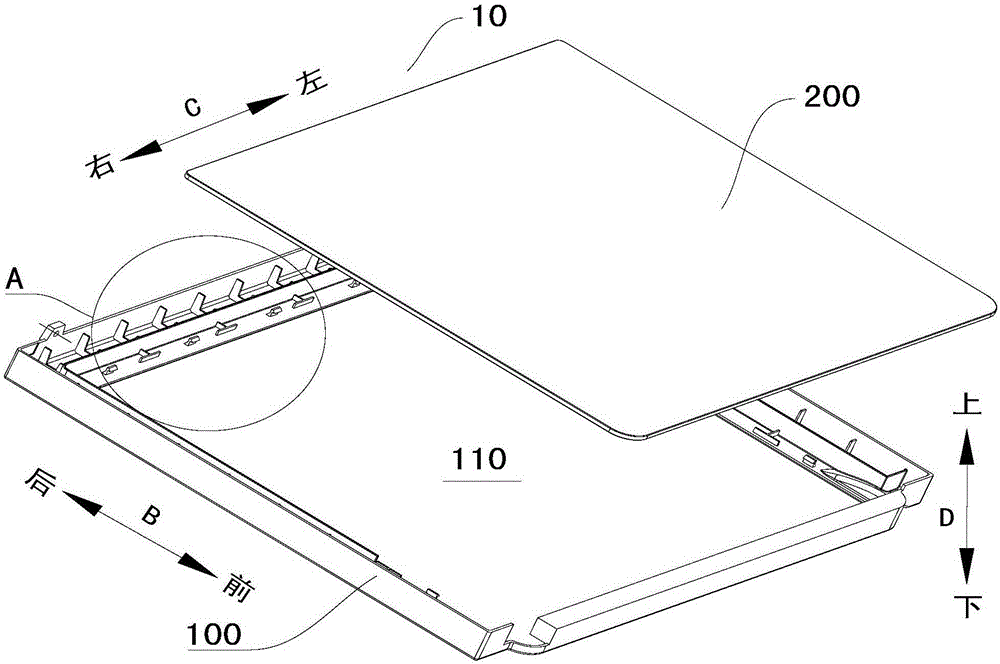

Top cover used for refrigeration device and refrigeration device provided with top cover

ActiveCN103499176AAppearance is rich and variedAvoid scratches and breakageDomestic cooling apparatusLighting and heating apparatusEngineeringSurface plate

The invention discloses a top cover used for a refrigeration device and the refrigeration device provided with the top cover. The top cover used for the refrigeration device comprises a frame and a surface board, wherein a containing hole is formed in the frame and the upper end of the containing hole is open; the surface board is detachably arranged in the containing hole and covers the containing hole. The top cover used for the refrigeration device has the advantages of being rich and diverse in appearance.

Owner:HEFEI HUALING CO LTD

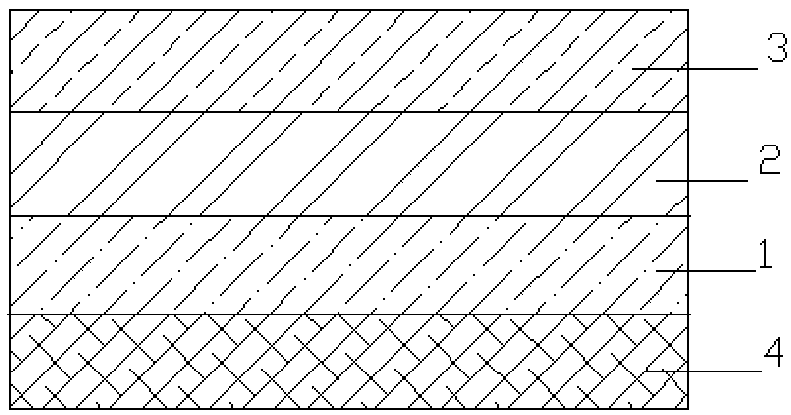

Flame retardant decorative sheet, manufacturing method of flame retardant decorative sheet and flame retardant material comprising flame retardant decorative sheet

InactiveCN108247786AImprove standardizationImprove aestheticsPlywood pressesWood treatment detailsAdhesiveEngineering

The invention provides a flame retardant decorative sheet and a manufacturing method of the flame retardant decorative sheet. The flame retardant decorative sheet comprises a board material assembly and a flame retardant adhesive layer which is at least attached to the surface of at least one side in the thickness direction of the board material assembly and formed by adhesive containing flame retardant adhesive. The board material assembly at least comprises a layer of wooden single board. The flame retardant adhesive contains water-soluble amino resin, dehydration catalyst, charring agent and assistant agent and contains water or not. The dehydration catalyst is one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate. The polymerization degree of the ammonium polyphosphate is 20 or above. The invention further provides a flame retardant material. The bonding performance of the flame retardant decorative sheet made by the adoption of the manufacturingmethod can meet the national standard requirement, and the flame retardant decorative sheet gives the flame retardant property to a base material and does not influence the mechanical property of thebase material. The formaldehyde emission is at the E1 grade or above, and the flame retardant decorative sheet is safe and environmentally friendly. Meanwhile, the nature texture of the wood is kept,and the decorative effect is good.

Owner:肖群伟

Impact-resistant polyurethane surface decoration material

InactiveCN108930378AStir wellImprove insulation effectCovering/liningsCoatingsCalcium silicateUV curing

The invention discloses an impact-resistant polyurethane surface decoration material. Two major processes are included, firstly, the primer line processing technological process comprises the specificsteps that (1) fixed-thickness sanding and dust removing are conducted, (2) seal coat is roller-painted on the back face and cured into a first UV seal coat layer, (3) a UV penetrant is roller-painted by two times, (4) infrared leveling is conducted, (5) UV putty is painted on the front face, UV is cured to generate a UV putty layer, (6) UV seal coat are roller-painted by three times and cured togenerate three second UV seal coat layers, and (7) fine sanding is conducted; and secondly, the finishing coat line roller-painting technological process comprises the specific steps that (1) dust removing is conducted, (2) UV glue is roller-painted to generate a first UV glue layer, and (3) UV finishing coat is painted by five times and cured to generate five UV finishing coat layers. Accordingto the impact-resistant polyurethane surface decoration material, strong penetration, rapid penetration and deep penetration of the UV curing penetrant and a fiber reinforced calcium silicate plate ora fiber cement plate are achieved, a film is formed through deep curing, the UV curing penetrant, the UV putty and the UV seal coat form a three-dimensional chemical netted crosslinking reaction, andthe problem of adhesive force of a decoration face layer and a base plate can be solved.

Owner:秦玲志

Two-slice wheel

InactiveCN105270087AAvoid the risk of falling off the hubImprove mechanical propertiesRimsEngineeringAtmospheric pressure

The invention relates to an automobile wheel, in particular to a two-slice wheel. The wheel comprises a wheel hub, wherein the wheel hub comprises a front wheel rim slice and a rear wheel rim slice; the front wheel rim slice and the rear wheel rim slice are fixedly connected together through bolts and are formed into an integral structure; the front wheel rim slice is in a conical tubular shape, and comprises an outer wheel flange, a first annular mounting part and wheel spokes; positioning clamping grooves and mounting threaded holes are formed in the first annular mounting part; a second annular mounting part is arranged at one side of the rear wheel rim slice; mounting through holes corresponding to the mounting threaded holes are formed in the second annular mounting part, and positioning lug bosses which can be connected with the corresponding positioning clamping grooves in a clamped manner are arranged on the second annular mounting part; a convex inner wheel flange is arranged at the other side of the rear wheel rim slice; the front wheel rim slice and the rear wheel rim slice are connected together in a positioning manner through the first annular mounting part and the second annular mounting part, and are fixed through the bolts. Through the adoption of the two-slice wheel disclosed by the invention, the mechanical performance is greatly improved, the cost is reduced, the risk that a tyre is liable to be separated from the wheel hub during running of a vehicle when the air pressure of the tyre is insufficient is avoided.

Owner:宁波市鄞州雄达车辆配件厂

Manufacturing method of outer wall heat-preservation decorating plate with vacuum heat-insulation function

InactiveCN108222397AImprove standardizationImprove aestheticsCovering/liningsFlooringCalcium silicateLacquer

The invention discloses a manufacturing method of an outer wall heat-preservation decorating plate with a vacuum heat-insulation function and further provides a flame-retardant material. The manufacturing method comprises two procedures, namely the primer line processing technical procedure and the finishing coat line roller-coating technical procedure. The primer line processing technical procedure comprises the specific steps that 1, constant-thickness sanding and dust removing are conducted; 2, roller-coating of back surface seal coat is conducted, and the back surface seal coat is cured into a first UV seal coat layer; 3, roller-coating of ultraviolet (UV) penetrating agents is conducted for two times; 4, infrared leveling is conducted; 5, the front surface is coated with UV putty, andUV curing is conducted to generate a UV putty layer; 6, roller-coating of the UV seal coat is conducted for three times, and the UV seal coat is cured to generate three second UV seal coat layers; and 7, fine sanding is conducted. The finishing coat line roller-coating technical procedure comprises the specific steps that 1, dust removing is conducted; 2, roller-coating of UV glue is conducted togenerate a first UV glue layer; and 3, UV finishing coat is smeared for five times and cured to generate five UV finishing coat layers. According to the manufacturing method of the outer wall heat-preservation decorating plate with the vacuum heat-insulation function, strong, rapid and deep permeation of UV curing penetrating agents and a fiber-reinforced calcium silicate plate or a fiber cementplate can be achieved, deep curing film-forming is achieved, the UV curing penetrating agents, the UV putty and the UV seal coat form a stereo chemical net-shaped cross-linking reaction, and the adhesive force problem of a decorating face layer and a base plate can be solved. The gluing property of the flame-retardant decorating plate prepared through the manufacturing method meets the national standard requirement, and a base material has the flame-retardant property; the mechanical property of the base material is not affected, the formaldehyde emission is also in the grade E1 or above, andthus safety and environmental protection are achieved; and meanwhile, the natural texture of wood is kept, and the decorating effect is good.

Owner:李石燕

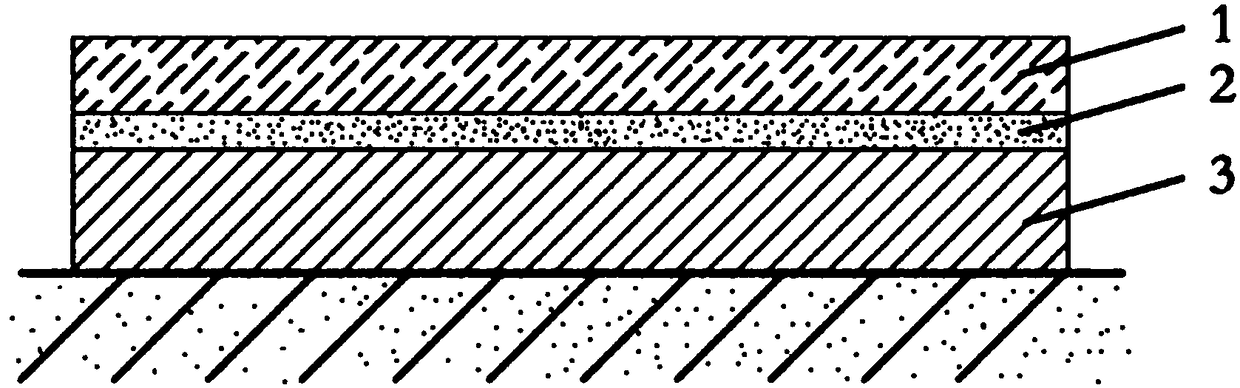

Outer wall heat-insulating decoration plate structure

InactiveCN108252470AEliminate hot and cold bridge phenomenonImproving the thermal insulation and decoration structure of the external wallCovering/liningsCalcium silicateKeel

The invention relates to a decoration structure, in particular to an outer wall heat-insulating decoration plate structure for a building outer wall, a vehicle-ship outer wall and the like, and further provides a fire retardant material. The outer wall heat-insulating decoration plate structure comprises a base layer wall body, a keel, fixing screws and a heat-insulating decoration plate, the heat-insulating decoration plate is attached to the base layer wall body, and the other side of the heat-insulating decoration plate is fixedly connected with the keel. The outer wall heat-insulating decoration plate structure is an environment-friendly heat-insulating decoration composite plate which has excellent performance of high pressure resistance, non-water-absorbing performance, damp proofing, airtighness, small weight, corrosion resistance, long service life, low heat conduction coefficient and the like. According to the outer wall heat-insulating decoration plate structure, the problemsof strong, rapid and deep permeation of an ultraviolet photocuring permeating agent and a fiber reinforced calcium silicate plate or a fiber cement plate can be solved, the deep layer is solidified into films and can form a three-dimensional chemical net-shaped cross-linking reaction with UV putty and UV closed paint, and the problem of adhesive force of a decoration face layer and a base plate can be solved. The bonding performance of a fire retardant decoration plate prepared through the method meets the national standard requirement, and a base material has fire retardant performance; themechanical performance of the base material is not affected, the releasing quantity of formaldehyde reaches the grade E1 or above, and safety and environment protection are achieved; and meanwhile, the natural texture of woods is kept, and the decoration effect is good.

Owner:肖群伟

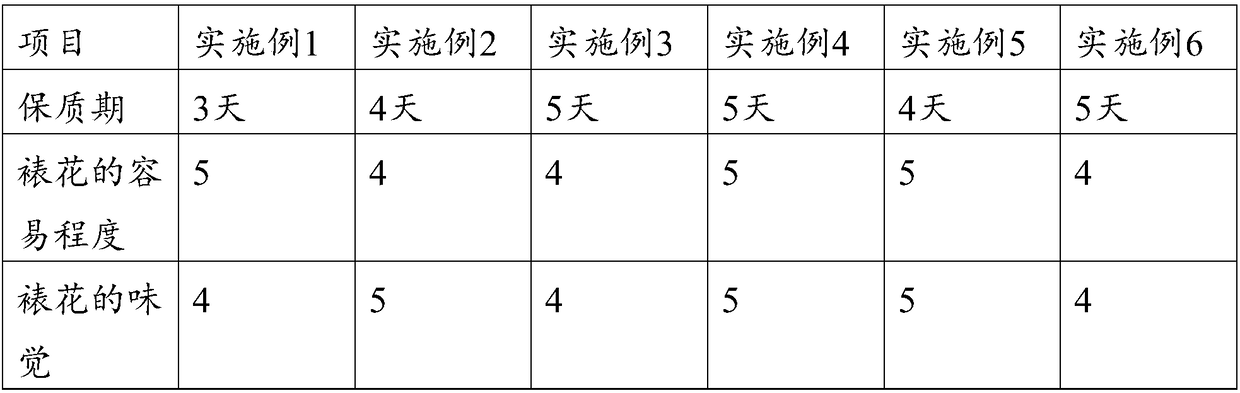

Polysaccharide red yeast rice food therapy material for mounting patterns and preparation method of polysaccharide red yeast rice food therapy material

InactiveCN108294084AAvoid pollutionAvoid it happening againModified nutritive productsBiotechnologyRed yeast rice

The invention discloses a polysaccharide red yeast rice food therapy material for mounting patterns. The polysaccharide red yeast rice food therapy material is mainly prepared from the following raw materials of 200-320 parts of red bean paste, 20-100 parts of cream, 1-10 parts of polysaccharide red yeast rice powder, and 0.1-1 part of pigment, wherein the polysaccharide red yeast rice powder is red yeast rice monascus, can be preserved in Guangdong Province Microbiological Culture Collection Center on 28 November, 2016, with the biological preservation number of GDMCC No:60124. Correspondingly, the invention further provides a preparation method of the polysaccharide red yeast rice food therapy material for mounting patterns. The polysaccharide red yeast rice food therapy material is used, safe, delicious, not liable to deteriorate, and free from toxic and side effects, has the effect of immunity improving, and has food therapy effects.

Owner:广东省真红生物科技有限公司

Textured transfer membrane and production process thereof

PendingCN107901649AHot stamping trial is goodAppearance is rich and variedThermographyHot stampingSizing

The invention relates to the field of transfer membrane. A textured transfer membrane comprises a substrate layer, a release layer, an embossed sizing layer and a resin layer; the substrate layer is coated with the release layer; the release layer is coated with the embossed sizing layer; the back of the substrate layer is coated with the resin layer. The transfer membrane has lines, trialabilityof hot stamping is good, and appearance of production to be transferred can be more various and artistic

Owner:任福海

External wall fireproof flame-retardant composite heat-insulating decorative plate and preparation method thereof

InactiveCN108612279AIncrease packing densityHigh tensile strengthCovering/liningsSynthetic resin layered productsThermal insulationPolystyrene

The invention relates to an external wall fireproof flame-retardant composite heat-insulating decorative plate, comprising a water-soluble non-combustible ceramic protective layer, an organic-inorganic composite toughening layer and a flame-retardant thermal insulation layer. The organic-inorganic composite toughening layer is flame-retardant thermal insulation type polymer mortar, and has the following components: a cementitious material S, ceramic microbeads, hydroxyethyl methylcellulose, redispersible latex powders, limestone powders and modified expandable graphite. Components of the flame-retardant thermal insulation layer are: modified expandable polystyrene and modified expandable graphite. The flame-retardant heat-insulating plate is mounted on a wall surface by bonding and anchoring. Bonding performance of the flame-retardant decorative plate prepared by the method of the invention meets requirements of national standards and flame retardant properties are given to a base material. Furthermore, mechanical properties of the base material would not be influenced, and formaldehyde emission is above an E1 level, the decorative plate is safe and environmental-friendly. At the same time, natural texture of timber is maintained and decorative effect is good.

Owner:肖群伟

Outer wall heat-preservation decorative board structure

InactiveCN108729610AEliminate hot and cold bridge phenomenonImproving the thermal insulation and decoration structure of the external wallCovering/liningsPretreated surfacesEnvironmental resistanceCalcium silicate

The invention relates to a decorative structure, in particular to an outer wall heat-preservation decorative board structure used for outer walls of buildings, outer walls of cars and ships and the like. The outer wall heat-preservation decorative board structure comprises a base wall body, keels, fixing screws and heat-preservation decorative boards, the heat-preservation decorative boards are bonded to the base wall body, and the keels are fixedly connected to the other faces of the heat-preservation decorative boards; the outer wall heat-preservation decorative board structure is an environment-friendly heat-preservation composite board which has excellent performance such as great pressure resistance, a good water insulation effect, good moisture resistance, high air impermeability, light weight, excellent corrosion resistance, a long service life and low heat conductivity coefficients. The outer wall heat-preservation decorative board structure can solve the problems of high permeability, rapid permeability and deep permeability of ultraviolet-curable permeating agents and fiber-reinforced calcium silicate boards or fiber cement boards, is deeply solidified into membranes, undergoes a stereoscopic chemical network cross-linking reaction with UV putty and UV sealing paint and can solve the problem of an adhesion force of decorative surface layer and base plates. A flame-retardant material is also provided. The gluing performance of a flame-retardant decorative board prepared by a method meets the requirements of national standards, and a substrate has flame-retardant performance; furthermore, the mechanical performance of the substrate is not influenced, the emission amount of formaldehyde is also above the E1 level, and safety and environmental protection are achieved. At the same time, the natural texture of wood materials is maintained, and the decorative effect is good.

Owner:肖挺超

Production process for novel UV decorative plate

InactiveCN109107849AProduct quality is stableGood insulation performanceCovering/liningsPretreated surfacesChemical networkLacquer

The invention discloses a production process for a novel UV decorative plate. The production process includes two flows. Specific steps of each of the flows are as follows: I. a process flow of primerline processing: namely a step of (1) flatly sanding by using a sanding machine and removing dust, (2) roller painting back seal coat and solidifying into a first UV seal coat layer, (3) roller painting an UV penetrant twice, (4) performing infrared levelling, (5) front coating UV putty and performing UV curing to form an UV putty layer, (6) roller painting UV seal coat three times and respectively curing to form three layers of second UV seal coat layers, and (7) performing fine sanding; and II. a process flow of roller painting finish paint lines: namely a step of (1) removing the dust, (2)roller painting UV glue to form a first UV glue layer, and (3) painting UV finish coat five times and curing to form five layers of UV finish coat layers. The production process can solve problems that strong penetration, rapid penetration, deep penetration and deep curing into film of UV curing penetrants and fiber-reinforced calcium silicate boards or fiber cement boards, and a three-dimensional chemical network cross-linking reaction with the UV putty and the UV seal coat is formed, and can solve the problem of adhesion of a decorative surface layer and a substrate.

Owner:刘宇鹏

Energy-saving thermal insulation anti-seismic integrated wallboard

InactiveCN108240086AImprove standardizationImprove aestheticsCovering/liningsFlooringCalcium silicateInsulation layer

The invention discloses an energy-saving thermal insulation anti-seismic integrated wallboard. A decorative board is a multi-layer composite board, a surface layer is a fluorocarbon paint, a middle layer is a calcium silicate board, an inner layer is an insulation layer, and the insulation layer is sandwiched by a thin plate. The thin plate is an environment-friendly thermal insulation decorativecomposite board with high compression resistance, no water absorption, moisture resistance, air resistance, light weight, corrosion resistance, long service life and low thermal conductivity and the like. An uv-curable penetrating agent and a fiber reinforced calcium silicate board or a fiber cement with strong penetration, rapid infiltration, deep penetration, deep curing film can be solved, anda three-dimensional chemical network crosslinking reaction can be formed with an UV putty, an UV sealing paint. The adhesion problem of a decorative surface layer and the base plate can also be solved. The invention also provides a flame retardant material. Adhesion properties of an anti-flaming decorative board prepared by the method of the composite exterior decorative panels meet the requirements of the national standard and gives the base material the flame-retardant property; moreover, mechanical properties of the base material can not be influenced, and the formaldehyde emission is alsoabove E1 level, is safe and environmentally-friendly. At the same time, the natural texture of wood is kept, and decorative effect is good.

Owner:周金妹

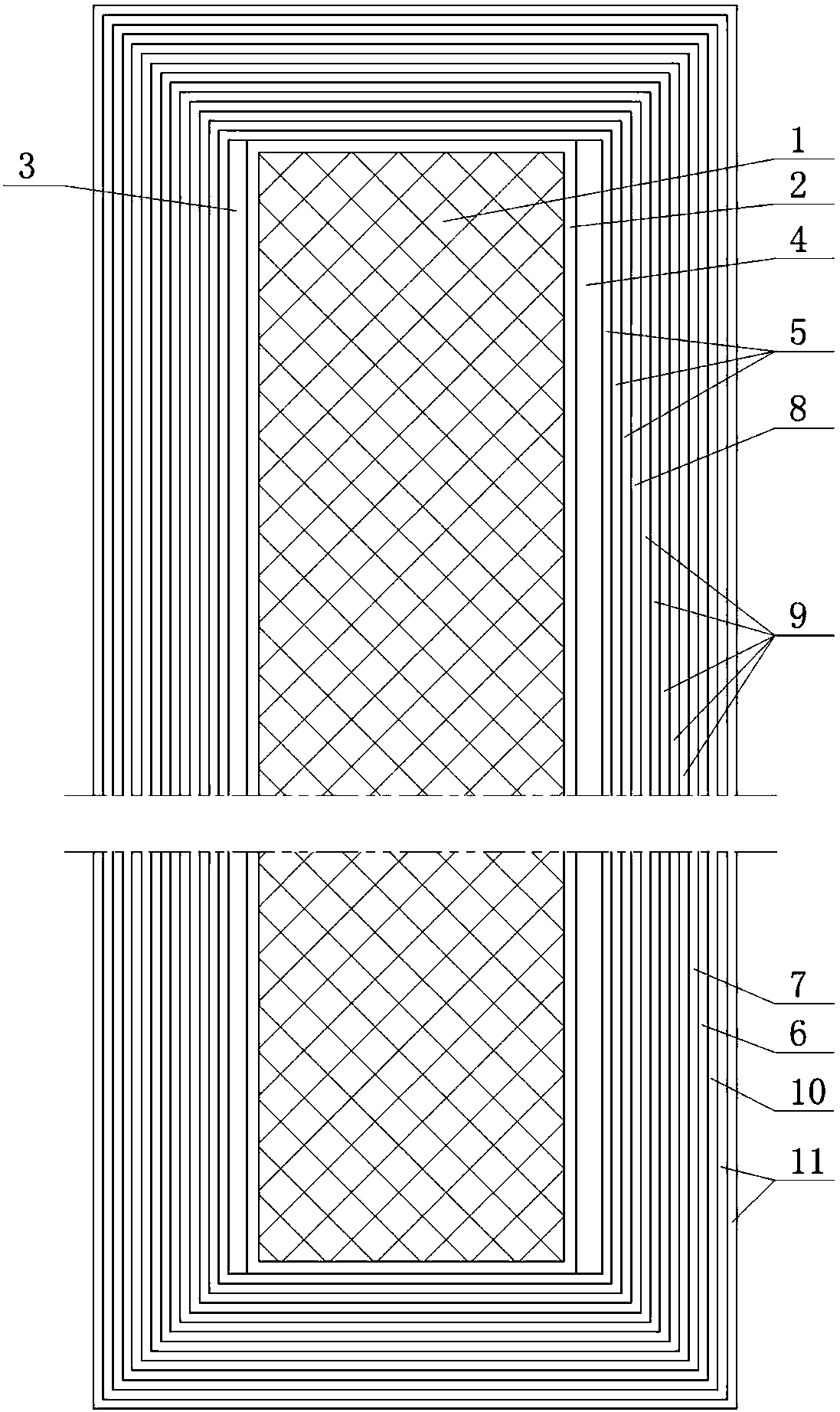

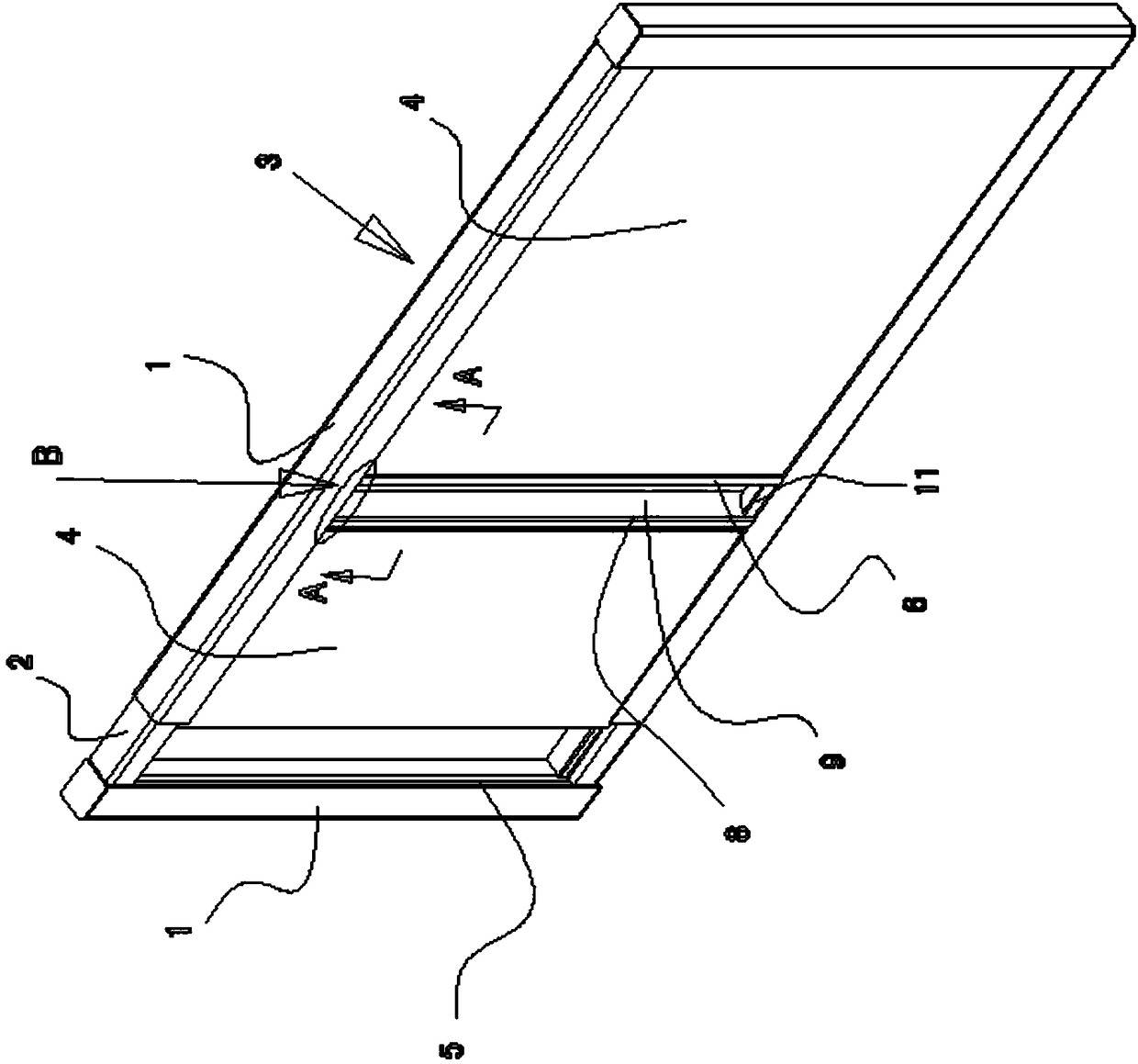

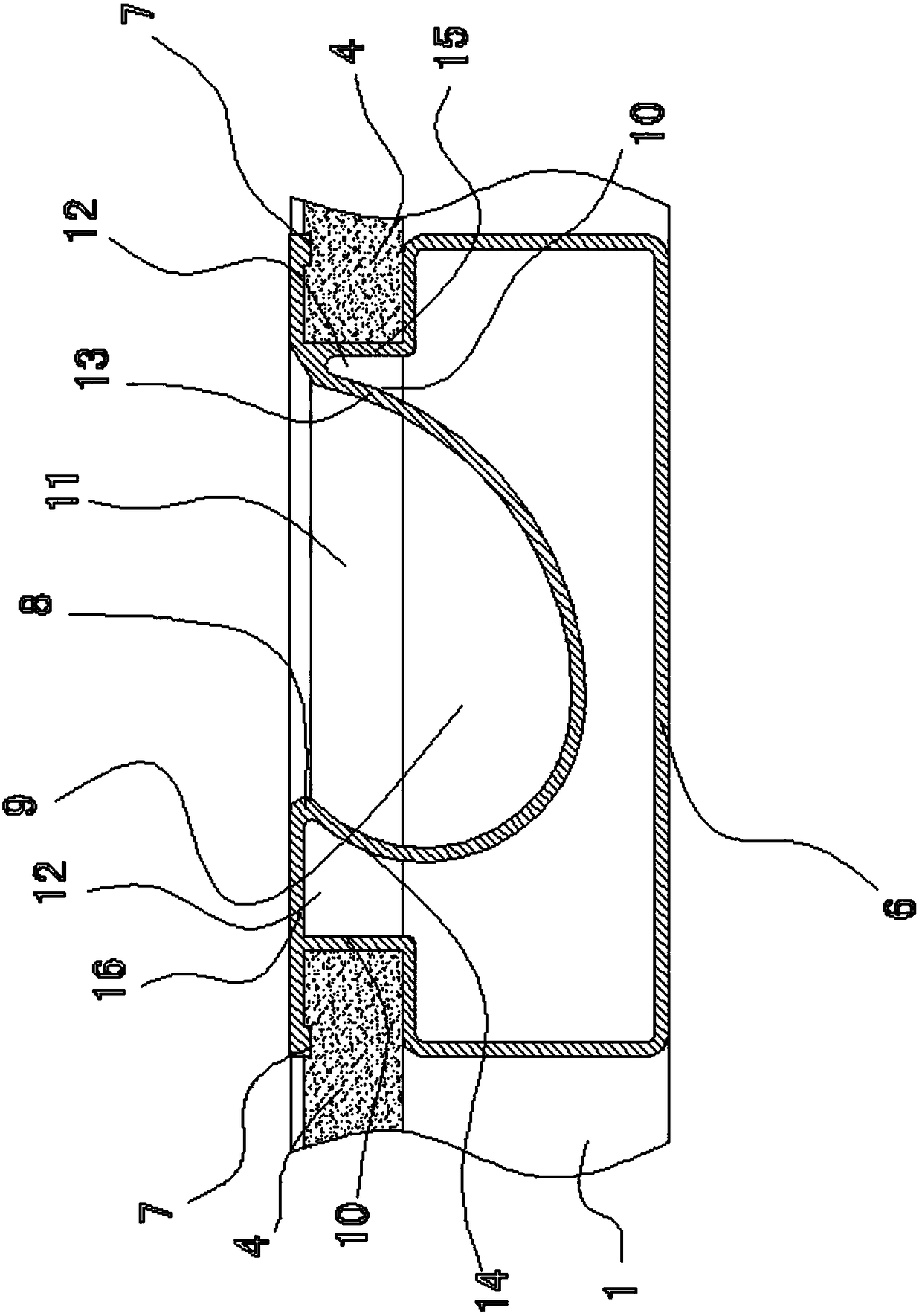

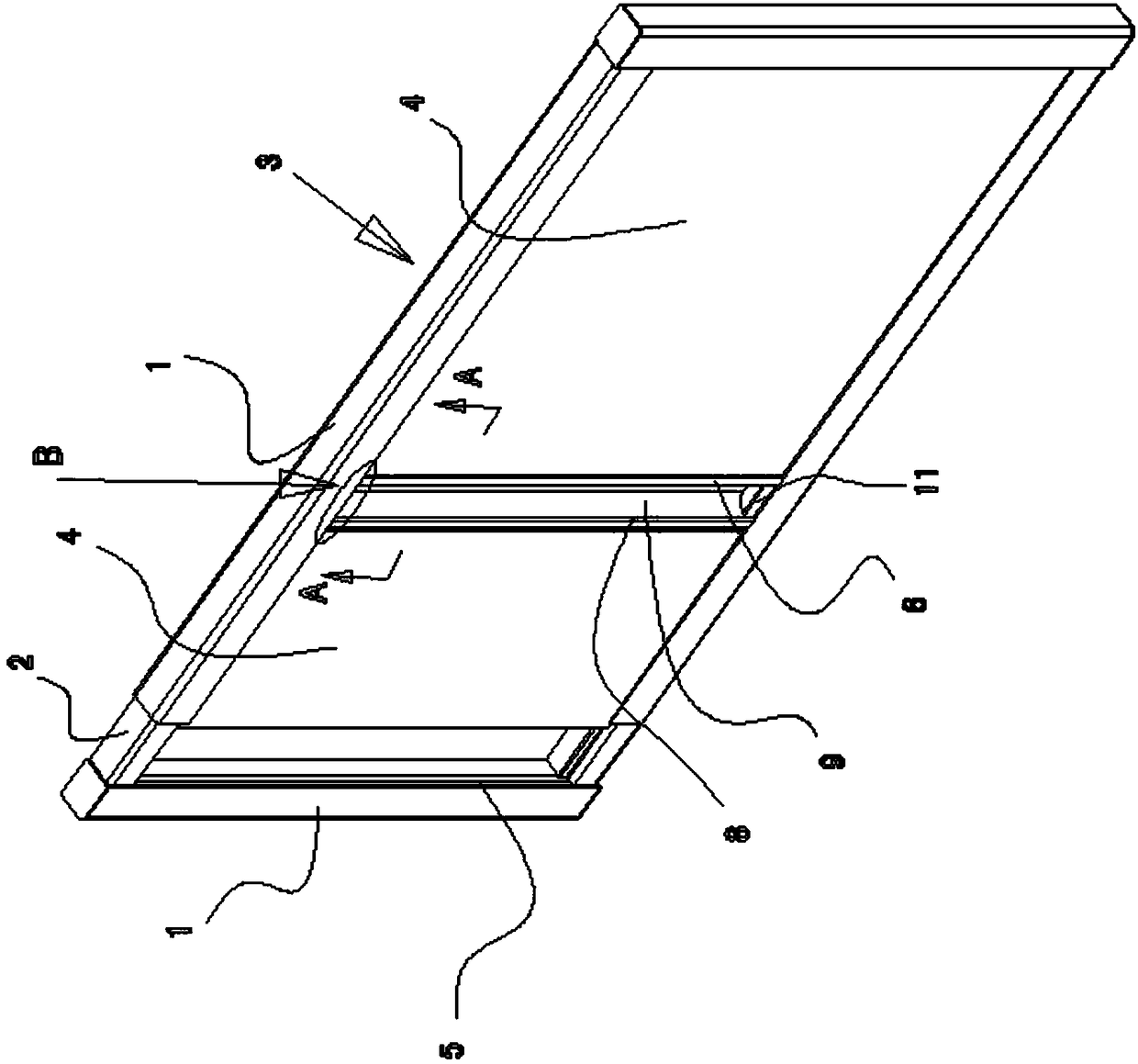

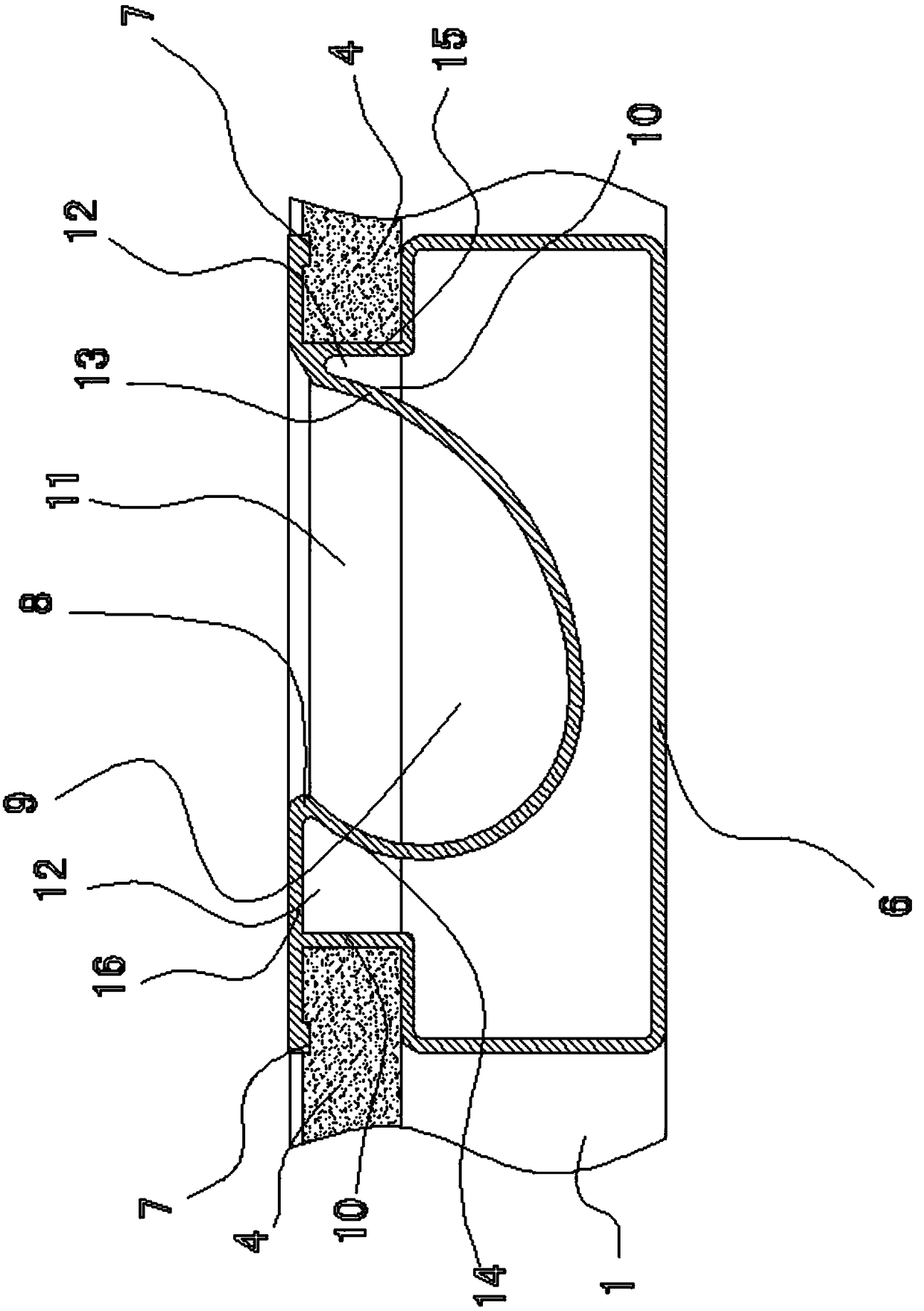

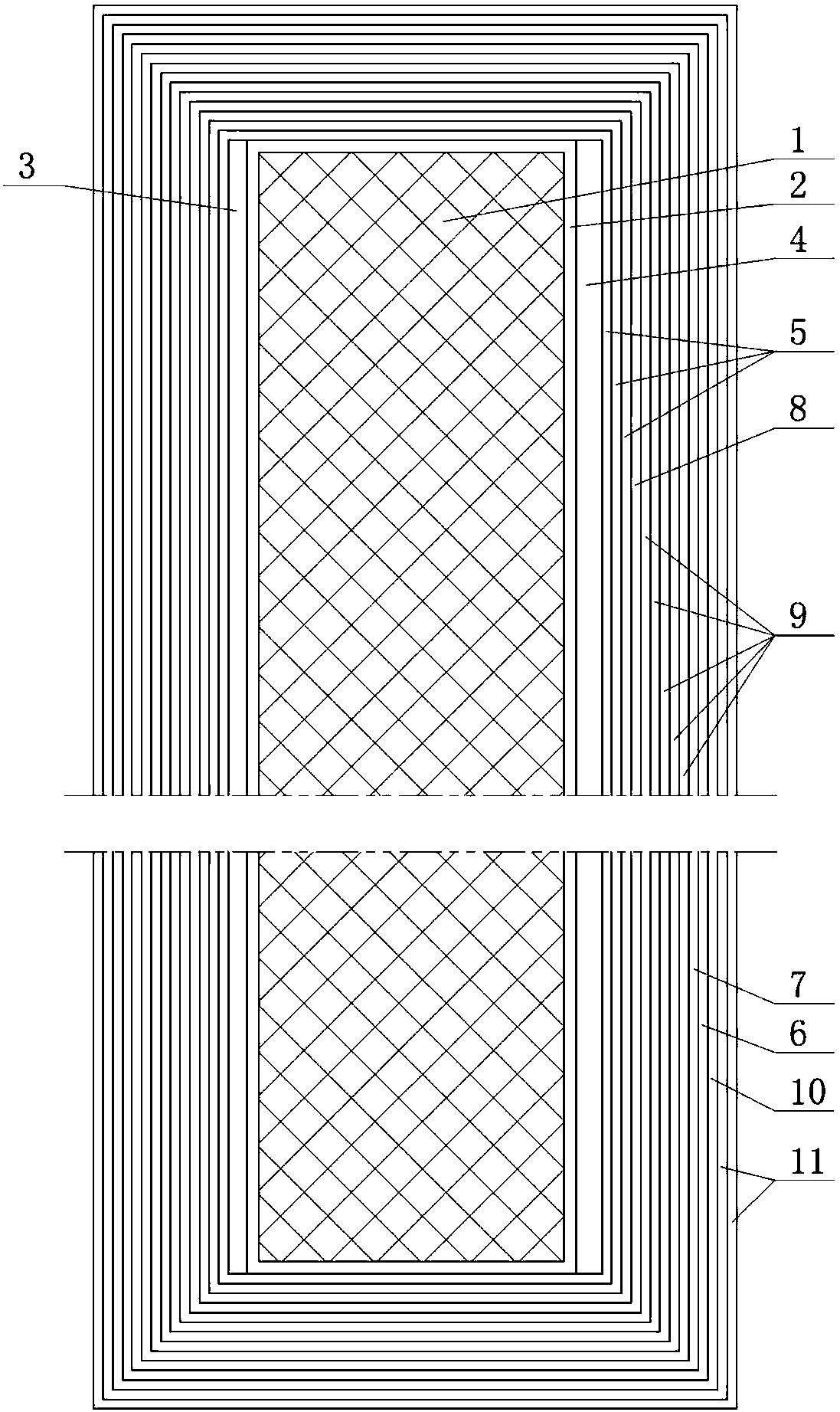

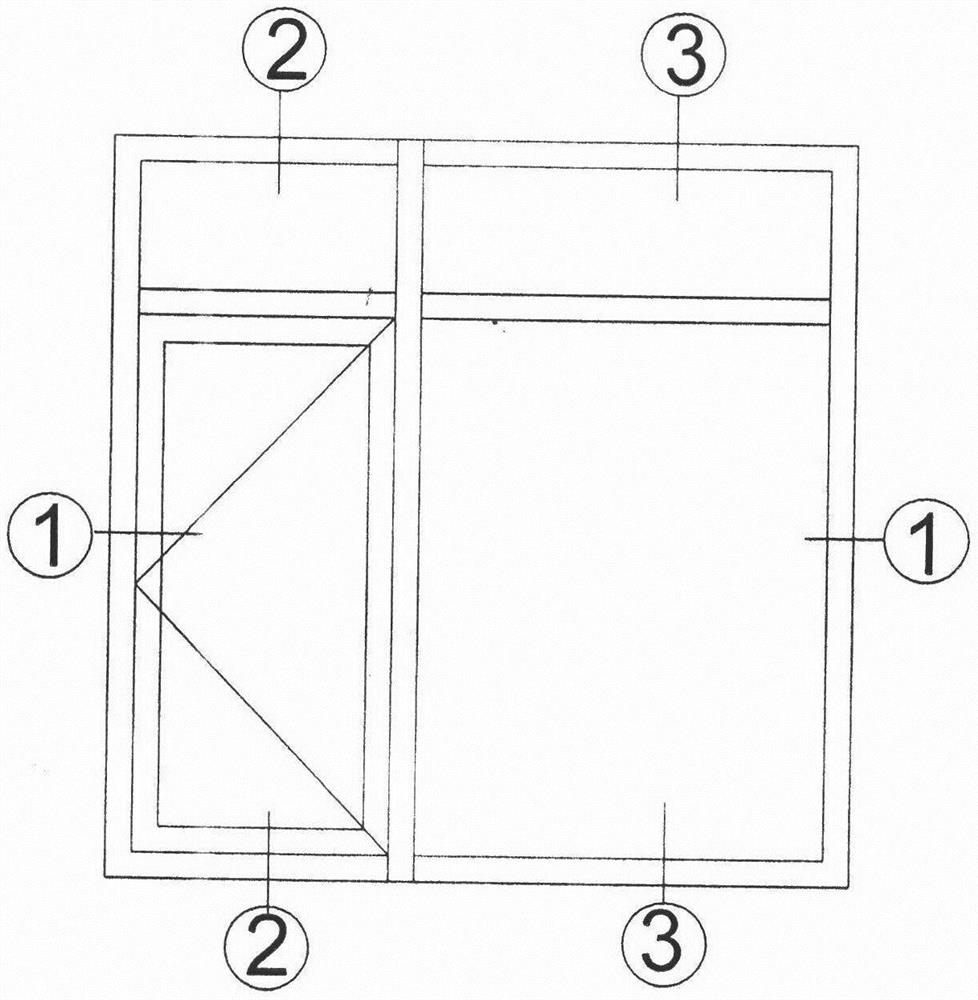

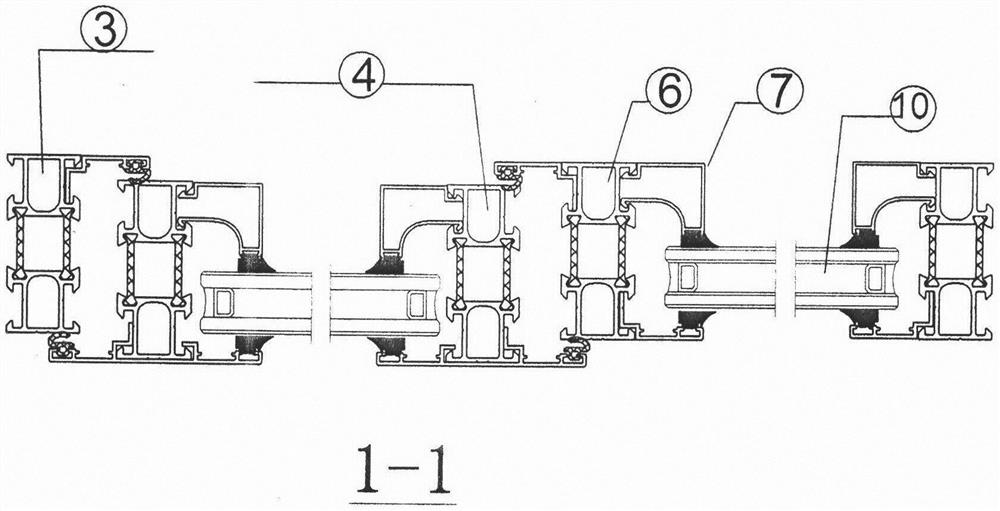

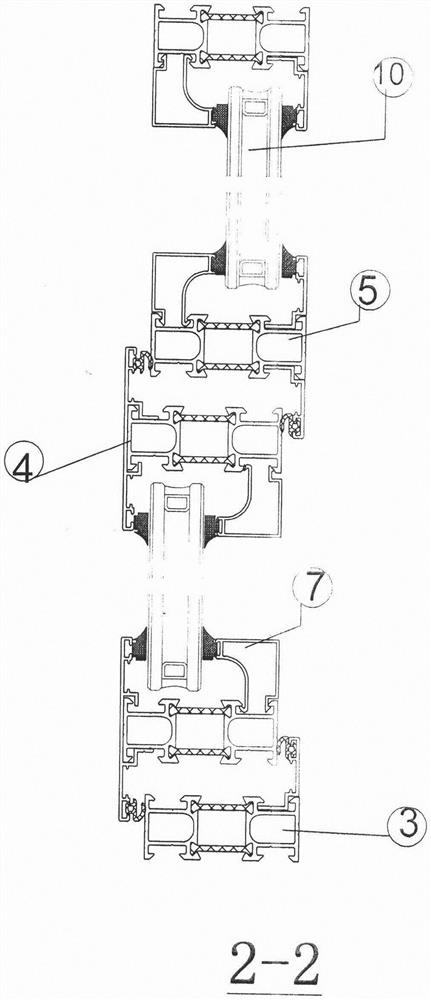

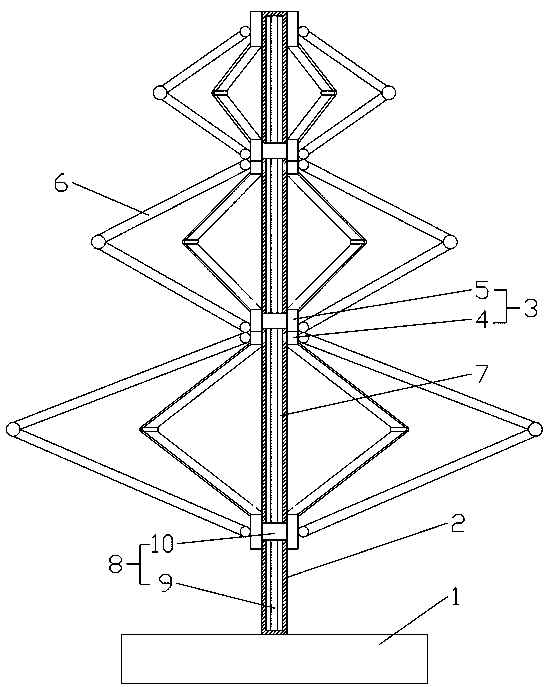

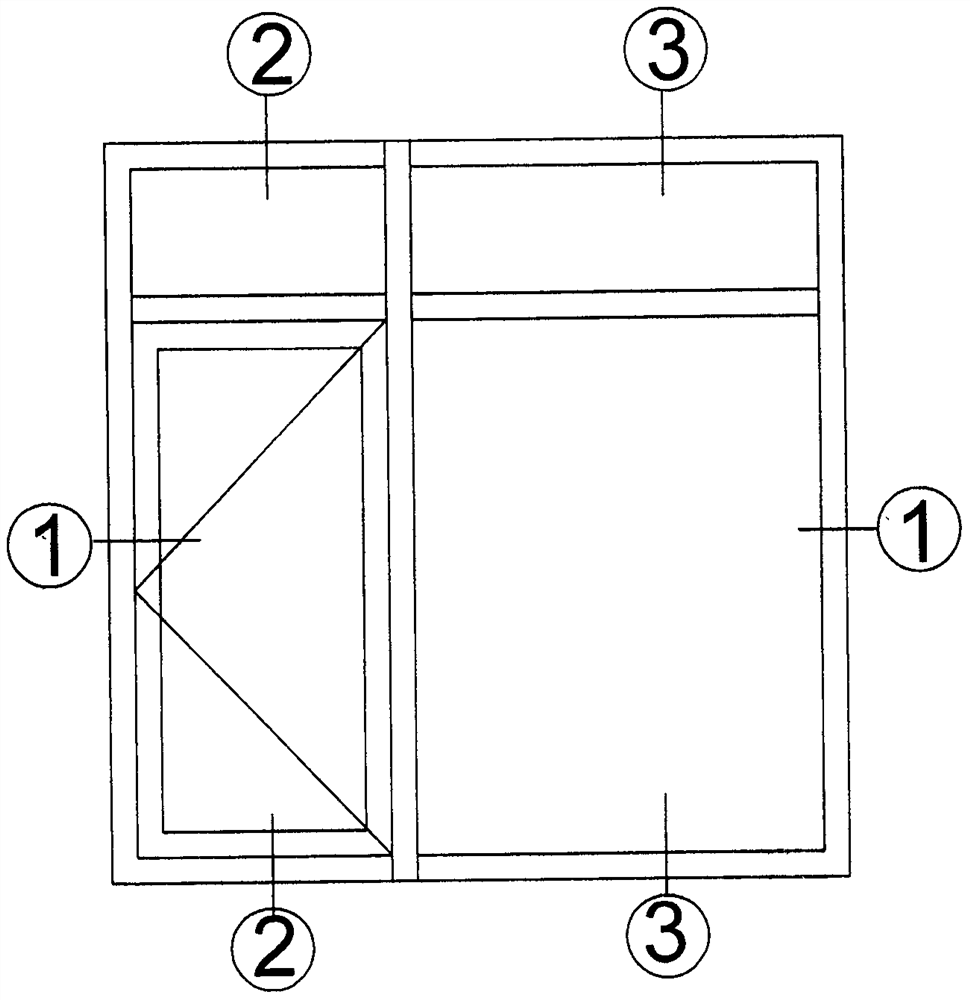

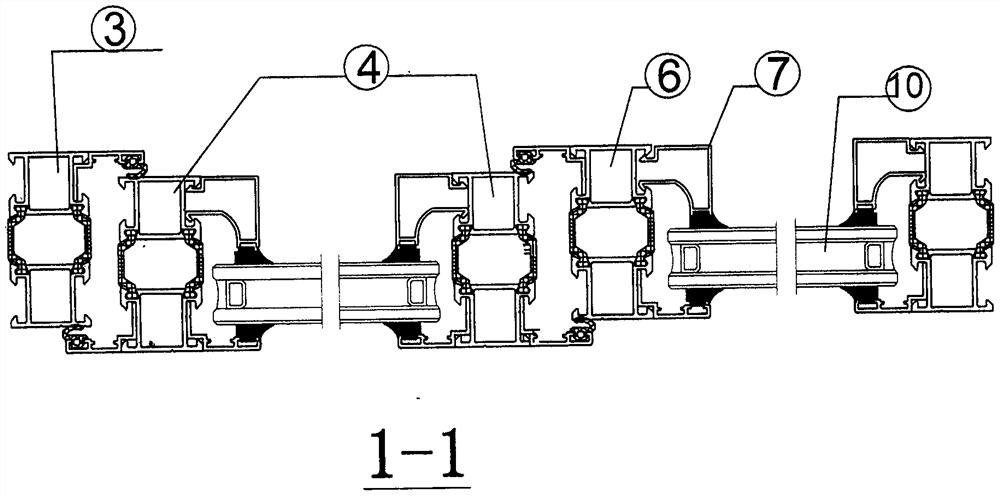

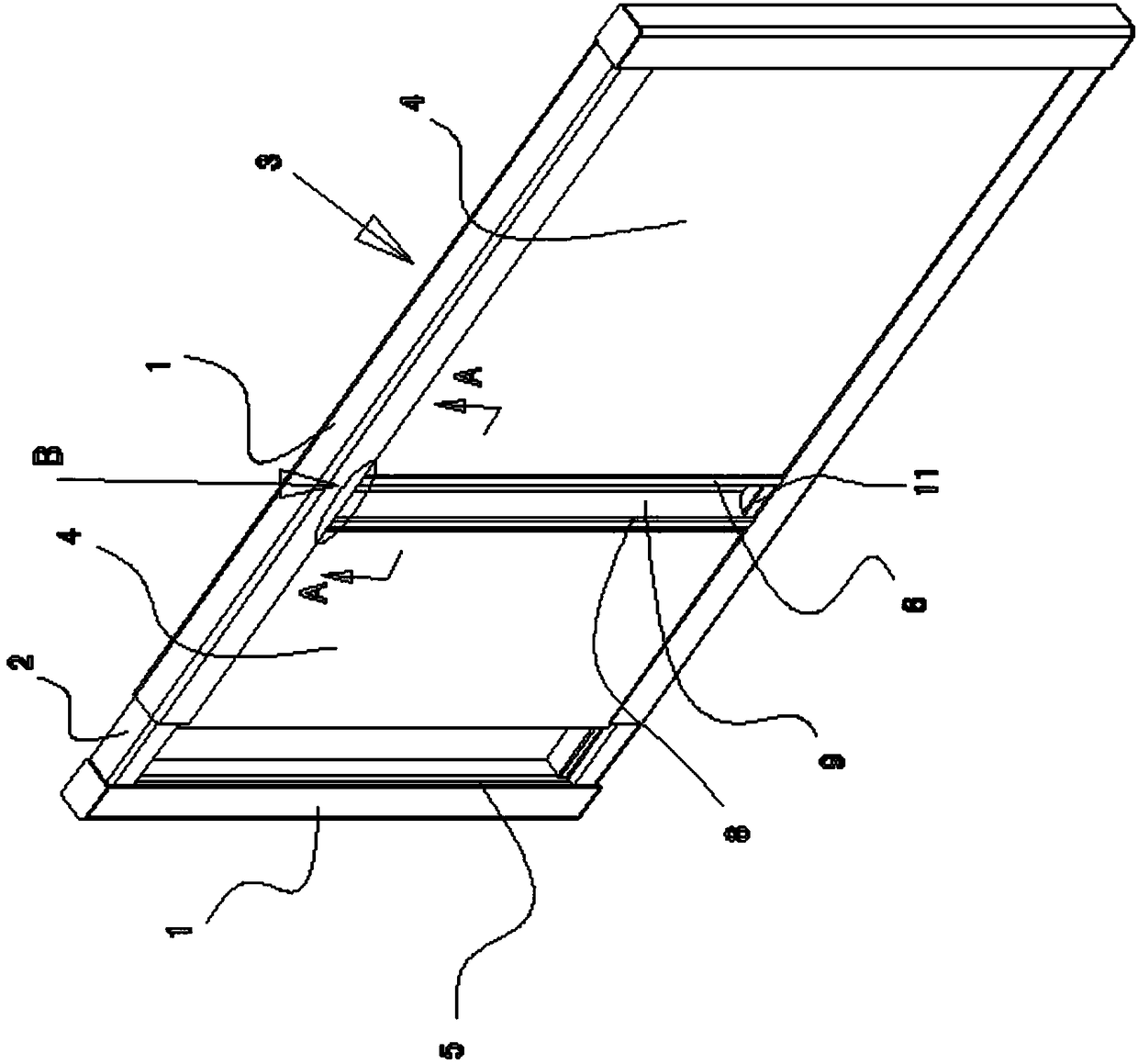

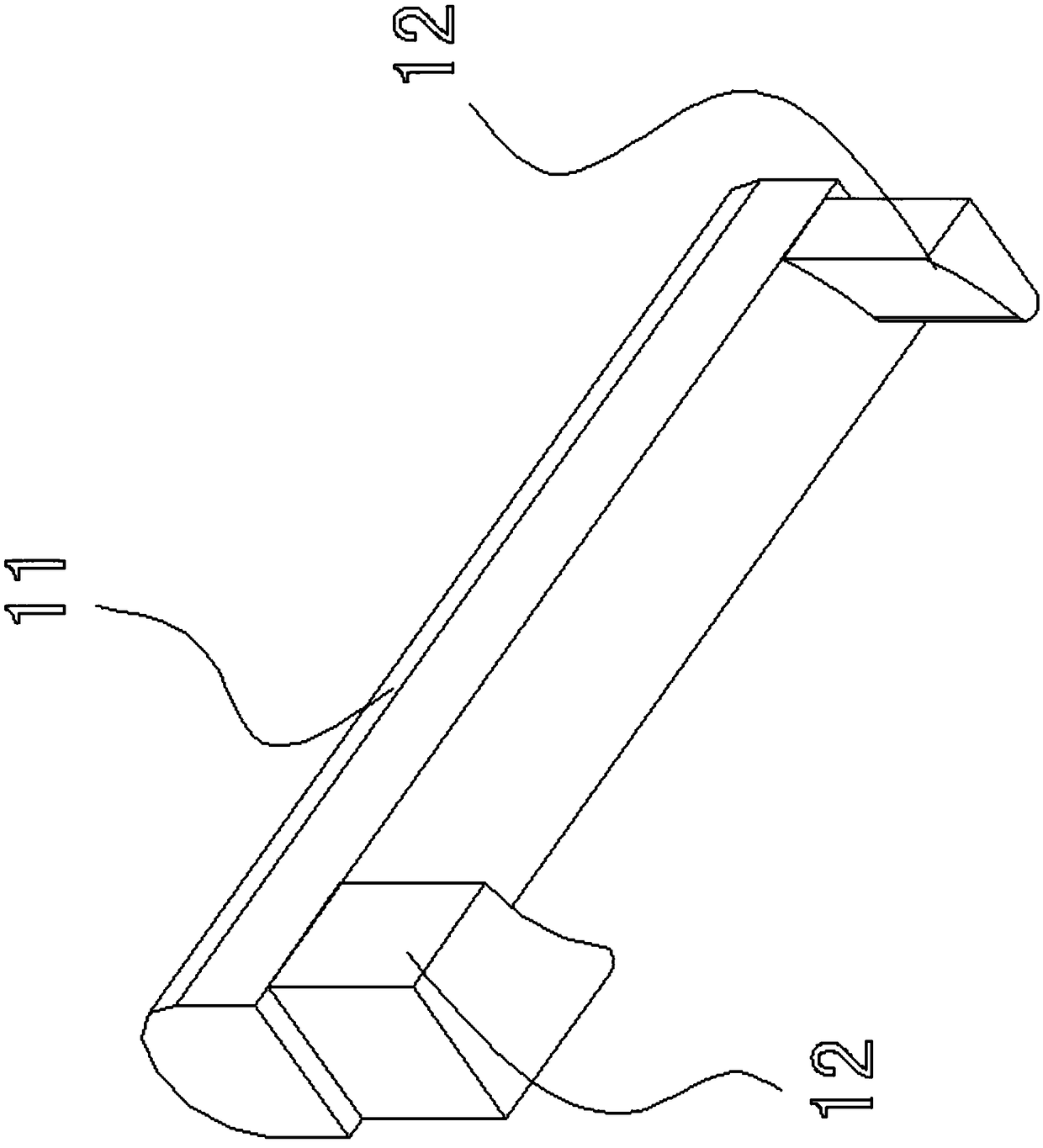

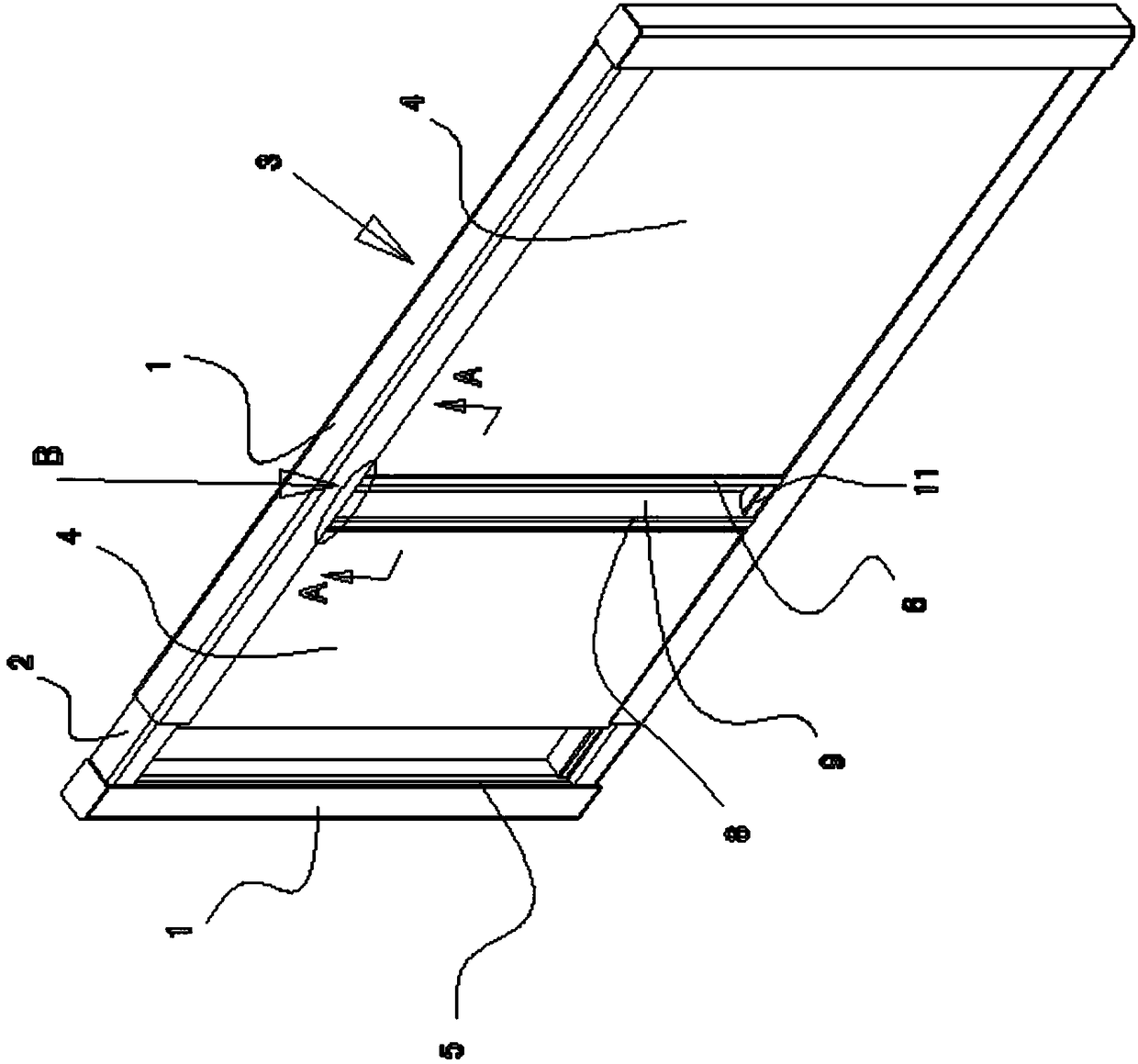

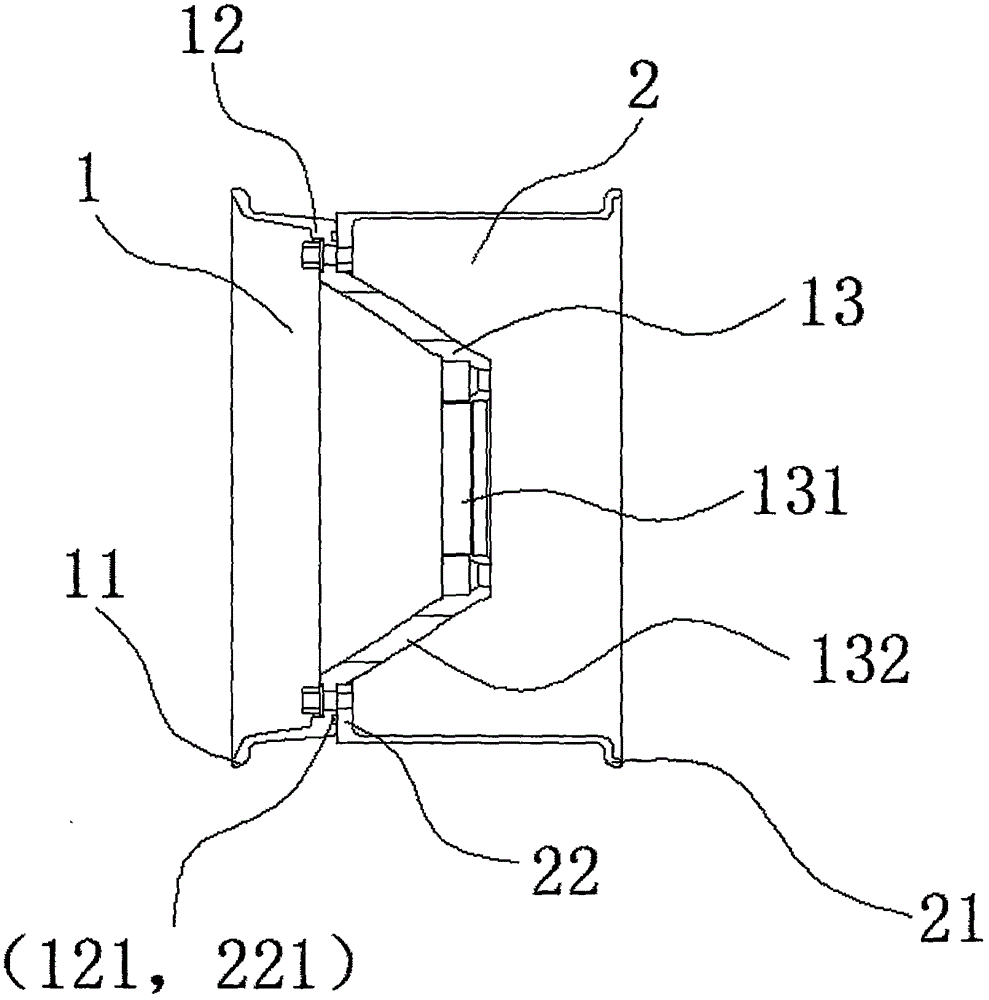

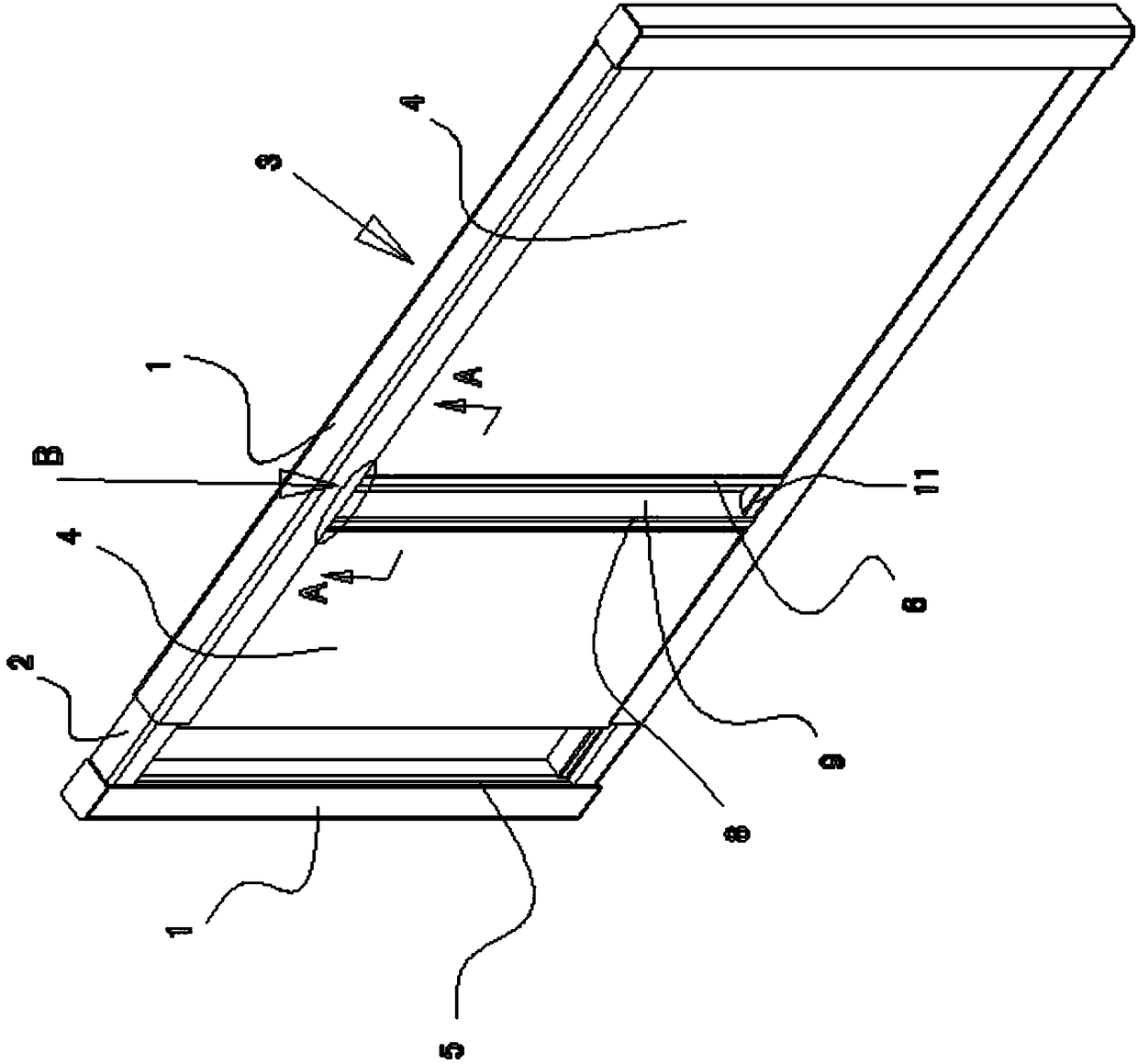

Universal profile and door and window system thereof

InactiveCN112240144AReduce typesAppearance is rich and variedWing arrangementsMechanical engineeringCurtain wall

The invention discloses universal profiles and a door and window system thereof, and particularly relates to a door and window curtain wall and profiles which are made of aluminum alloy or other rigidmaterials. The door and window system is the door and window curtain wall system which can manufacturing a casement door and window or a sliding door and window by utilizing several universal profiles. The invention further relates to a profile structure for forming the door and window curtain wall. According to the casement door and window system composed of the universal profiles and the structure thereof, main body profiles forming a door and window are all composed of column material profiles 1 and edging profiles 2 in a combined mode, and the column material profiles 1 are multi-cavity profiles and can be broken bridge profiles or non-broken bridge profiles. The column material profile 1 and the edging profile 2 can form a frame 3. The column material profile 1 and a fan cover 11 canform a fan material profile 4, or the column material profile 1 and the two edging profiles 2 can form a fan material profile 4A. The column material profile 1 and the two edging profiles 2 can forma mullion profile 5. The column material profile 1 and the two edging profiles 2 can also form a Z-mullion profile 6. The edging profiles 2 can be combined with the column material profiles 1 to formvarious profiles.

Owner:吴炜

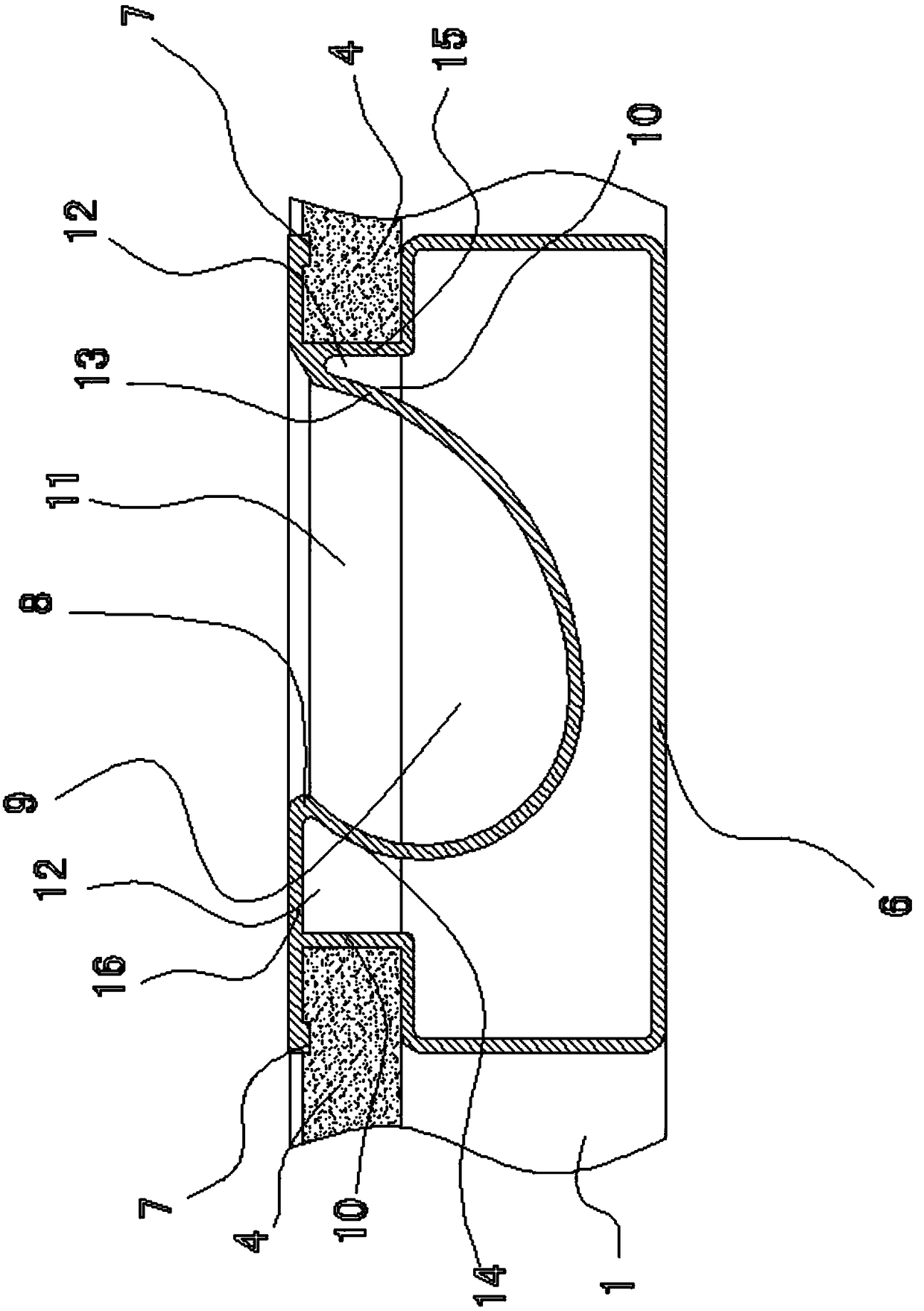

Door body for refrigerator and refrigerator provided with same

ActiveCN103486809BAppearance is rich and variedVarious shapesDomestic cooling apparatusLighting and heating apparatusEngineeringGlass sheet

Owner:HEFEI HUALING CO LTD

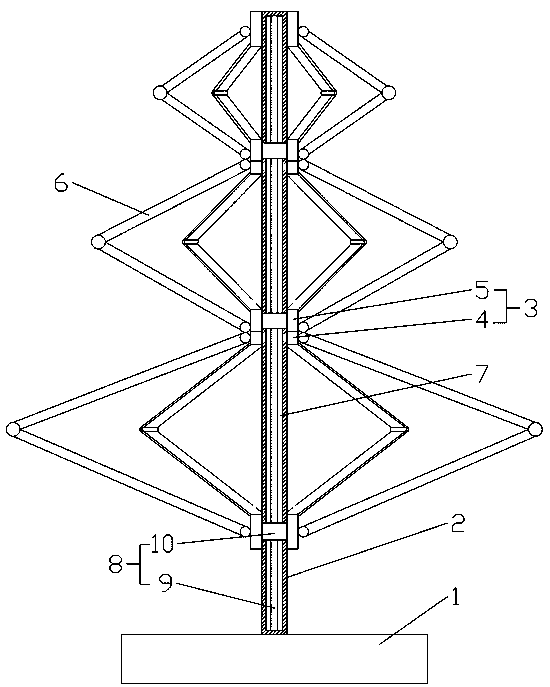

Christmas artware

InactiveCN111134518AAppearance is rich and variedImprove the decorative effectReligious equipmentEngineeringMechanical engineering

Owner:义乌市镔瑞工艺品有限公司

Exterior wall heat-preservation decorative plate structure

InactiveCN108252467AEliminate hot and cold bridge phenomenonImproving the thermal insulation and decoration structure of the external wallCovering/liningsFlooringCalcium silicateKeel

The invention relates to a decorative structure, in particular to an exterior wall heat-preservation decorative plate structure used for exterior walls of buildings, external walls of vehicles and ships, and the like. The exterior wall heat-preservation decorative plate structure comprises a basic layer wall, a keel, a fixing screw and a heat-preservation decorative plate; the heat-preservation decorative plate is attached to the basic layer wall, and the other face of the heat-preservation decorative plate is fixedly connected with the keel. An environment-friendly heat-preservation decorative composite plate has the excellent properties that the compression resistance is high, the non-water-absorbent, moistureproof, airtight, lightweight and corrosion resistant effects are achieved, theservice life is long, and the heat conductivity is low. According to the environment-friendly heat-preservation decorative composite plate, the problems of high penetration, quick penetration and deep-layer penetration of an ultraviolet light curing penetrant and a fiber-reinforced calcium silicate plate or a fiber cement plate can be solved, the environment-friendly heat-preservation decorative composite plate is deeply cured into a film, the environment-friendly heat-preservation decorative composite plate, UV putty and UV sealed paint form a three-dimensional chemical network crosslinking reaction, and the problem of adhesive force of a decorative face layer and a base plate can be solved. The invention further provides a flame-retardant material. The gluing property of the flame-retardant decorative plate prepared through the method can meet the national standard requirement, and a flame-retardant property is given to a basic material; the mechanical property of the basic materialis not affected, the formaldehyde releasing amount is also the E1 level or above, and the safe and environment-friendly effects are achieved; and meanwhile, the natural texture of wood is kept, and the decorative effect is good.

Owner:秦春玉

Polyvinyl chloride synthetic wood imitating material and preparing method thereof

InactiveCN109129753AImprove standardizationImprove aestheticsPressure wood treatmentWood treatment detailsWood veneerPolyvinyl chloride

The invention provides a polyvinyl chloride synthetic wood imitating material and a preparing method thereof. The polyvinyl chloride synthetic wood imitating material comprises a panel assembly and aninflaming retarding gluing agent layer, wherein the inflaming retarding gluing agent layer is at least attached to the surface of at least one side in the thickness direction of the panel assembly and is formed by a gluing agent containing an inflaming retarding gluing agent. The panel assembly at least comprises a layer of wood veneer. The inflaming retarding gluing agent contains water-solubleamino resin, a dehydrated catalyst, a carbon forming agent and an assistant agent and contains or does not contain water. The dehydrated catalyst is selected from one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate. The polymerization degree of the ammonium polyphosphate is 20 or above. The invention further provides an inflaming retarding material. The gluingperformance of the polyvinyl chloride synthetic wood imitating material prepared through the method meets the national standard requirement, and a base material is endowed with the inflaming retarding performance. In addition, the mechanical performance of the base material is not influenced, formaldehyde emission reaches the E1 level or above, and safety and environment friendliness are achieved; and meanwhile, the nature texture of the wood is kept, and the decoration effect is good.

Owner:秦春玉

Universal profile door and window system and profile

PendingCN111852254AAppearance is rich and variedSimple structureWindow/door framesWing framesClassical mechanicsMechanical engineering

The invention relates to a system for manufacturing a door and window curtain wall by using a plurality of universal profiles and the profiles thereof, in particular to the door and window curtain wall and the profiles made of aluminum alloy or other rigid materials, and also relates to the profiles forming the door and window curtain wall.

Owner:吴炜

Vacuum ion plating zirconium nitride copper decorative sheet

InactiveCN108612275AGuaranteed insulation effectPrevent mildewCovering/liningsGlass/slag layered productsCopperAluminum foil

The invention relates to a vacuum ion plating zirconium nitride copper decorative sheet. An external wall panel is connected with a base wall body through a keel. The external wall panel is formed bya surface decorative sheet layer cladding, a middle waterproof glass wool layer, and a dampproof aluminum foil veneer. Compared with the prior art, the decorative sheet is advantaged by good heat-insulating property, good decorative effect, low cost, and the decorative sheet is safe and durable.

Owner:肖群伟

Magnesian inorganic decorative integral plate

InactiveCN108252465AEasy to fixEasy to set upCovering/liningsFlooringNational standardMechanical property

The invention provides a magnesian inorganic decorative integral plate. The magnesian inorganic decorative integral plate comprises a frame body and a glass panel. A pipe-shaped handle aluminum alloyprofile is arranged on the magnesian inorganic decorative integral plate, and inlaid grooves are formed in the pipe-shaped handle aluminum alloy profile; a notch with a lintel is formed in the handlealuminum alloy profile, and two glass panels are inlaid on the two frame-shaped inlaid grooves of the frame body; a groove is formed in the pipe-shaped handle aluminum alloy profile, and an inlaid block is arranged on the pipe-shaped handle aluminum alloy profile; and inlaid feet are arranged on the inlaid block, and the inlaid block is inlaid in the inlaid grooves on the two sides of the frame body. Compared with the prior art, the magnesia inorganic decorative integral plate has the advantages that planes can form a plurality of decorative areas, and the position of a handle combined with analuminum alloy frame can adapt to the practical use. The invention further provides a flame retardant material. The adhesive property of a flame-retardant decorative plate prepared by the method canmeet the national standard, and the base material flame-retardant property can be achieved; the mechanical property of the base material is not affected, the release amount of formaldehyde is above E1level, and safety and environmental protection are achieved; and at the same time, the natural texture of wood is kept, and the decorative effect is good.

Owner:肖群伟

High-strength stretch-proof flame-retardant textile

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

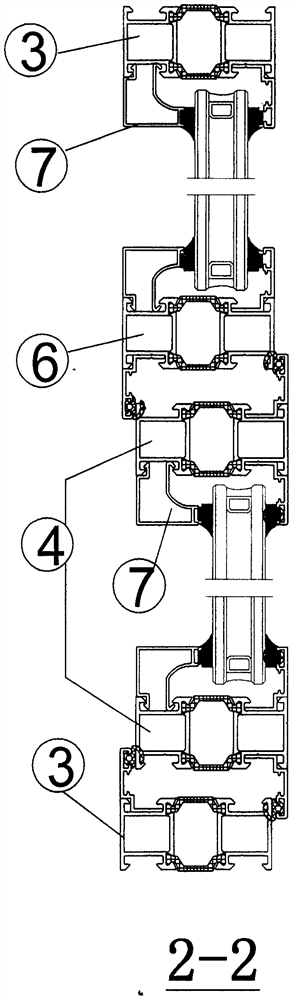

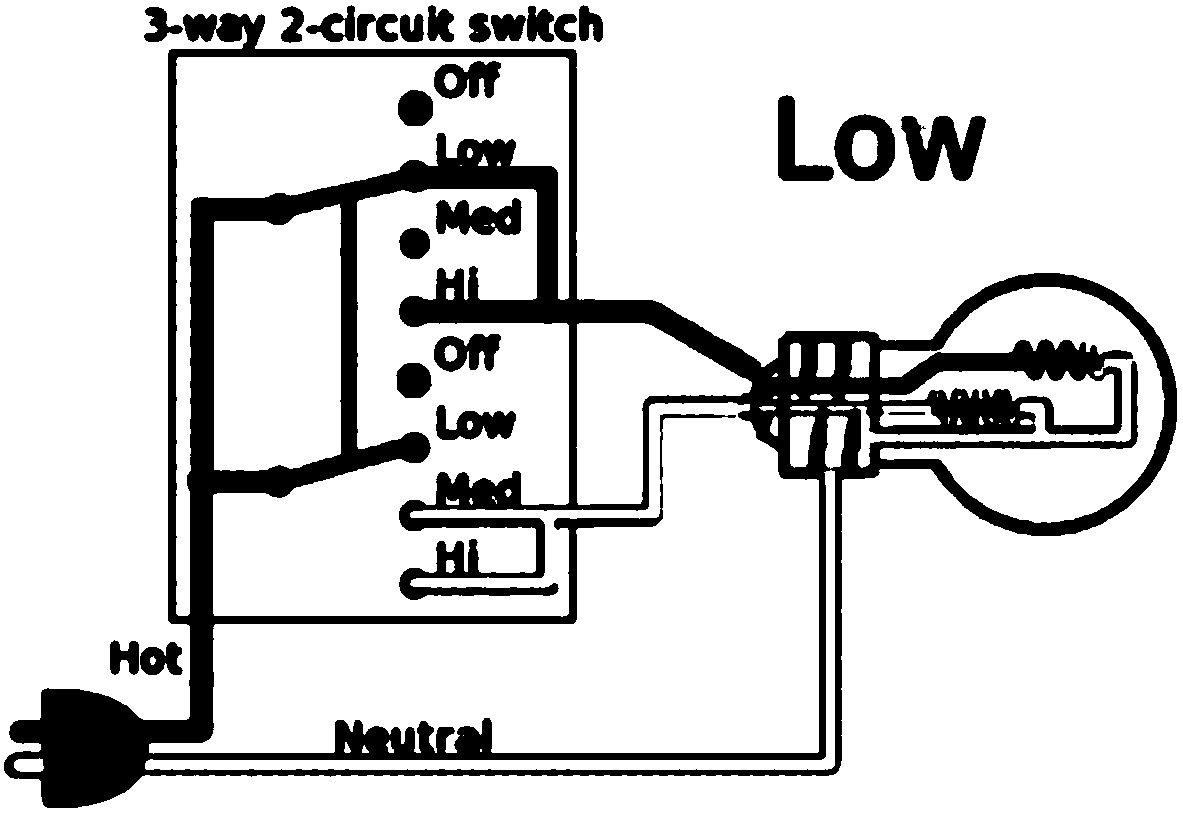

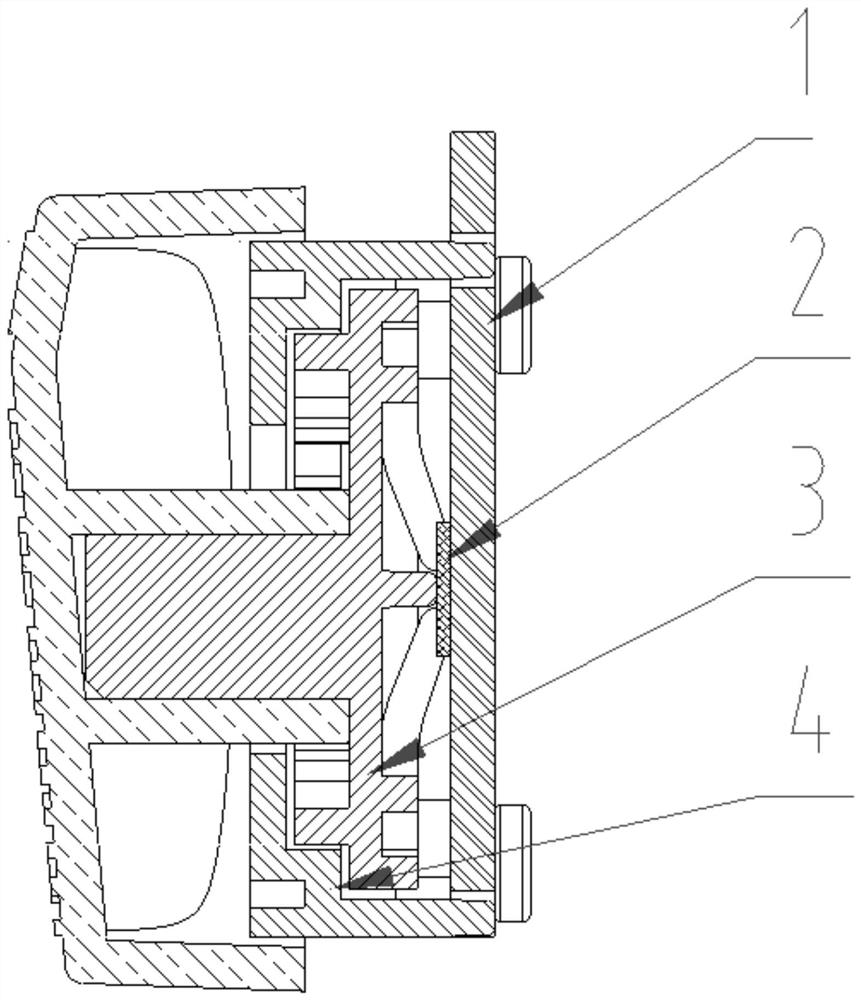

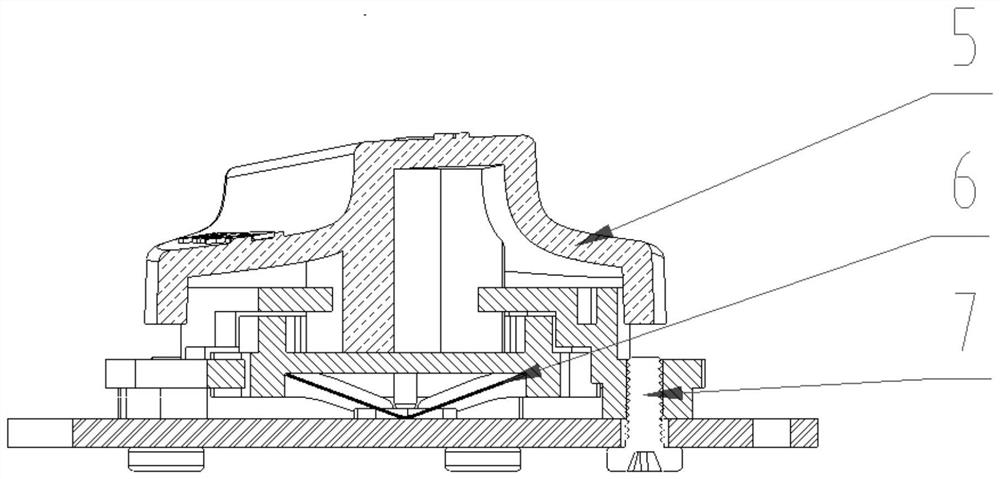

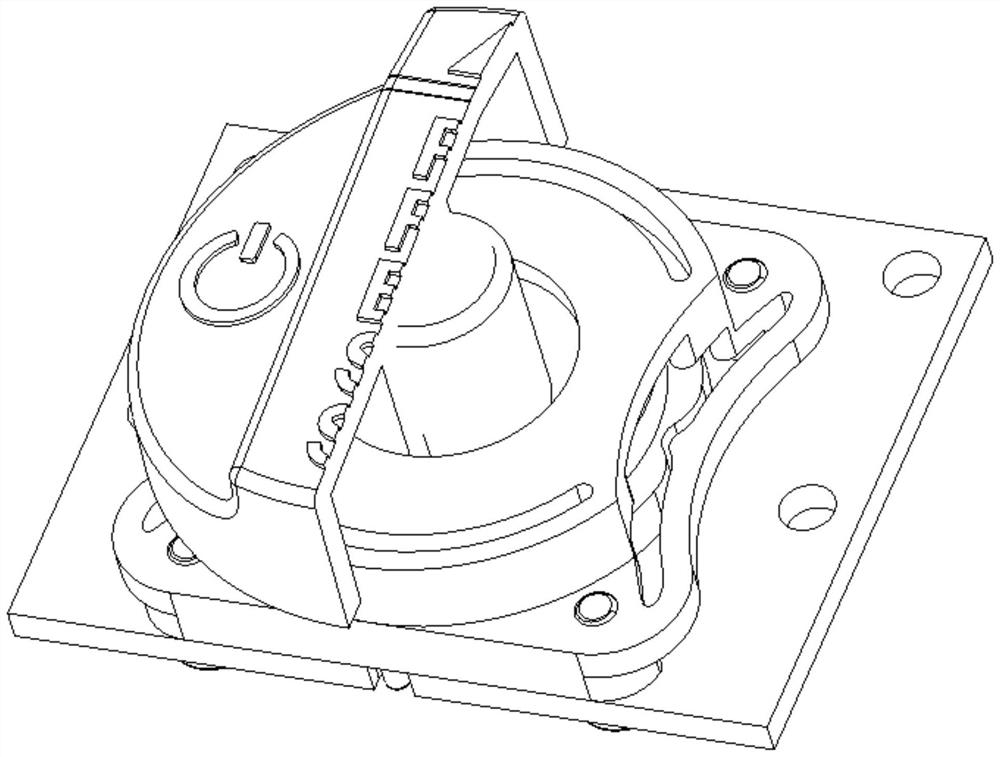

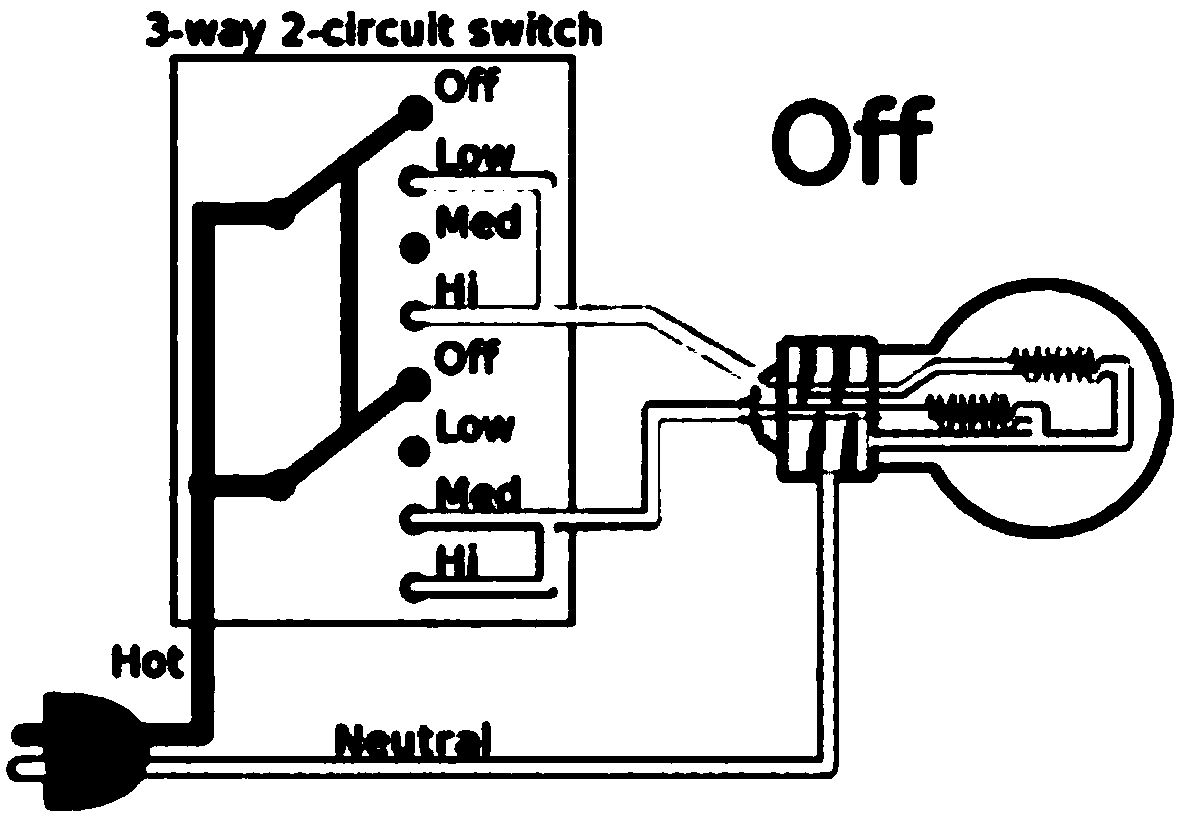

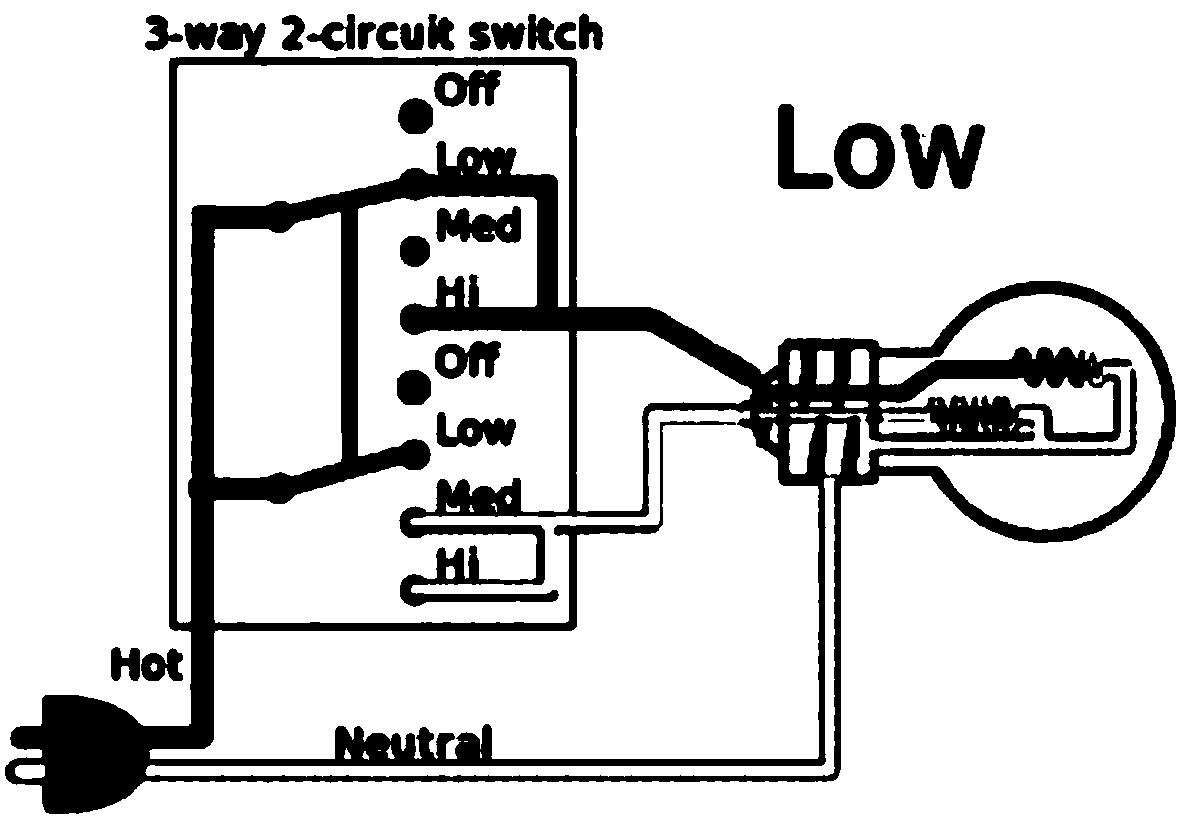

A rotary switch and its control method

ActiveCN107393759BVarious designsEasy to operateProgramme controlComputer controlRotary switchControl theory

The invention discloses a rotary switch and a control method thereof, comprising a PCB board, a dome, a first rotating mechanism, a second rotating mechanism, a rotating cap, a contact piece, and screws, and the second rotating mechanism is fixed on the PCB board through screws , the second rotating mechanism is connected with the first rotating mechanism, one end of the first rotating mechanism is connected with the rotating cap, the other end of the first rotating mechanism is connected with the contact sheet, the contact sheet is connected with the dome, and the dome is connected with the PCB board catch. The rotary switch of the present invention realizes different gears when rotating through the plastic structure, and the plastic of the rotating part rotates to different positions to drive the contact piece to trigger different functions. At the same time, long press and short press the knob can also achieve different controls. The principle is that when the knob is in different positions or pressed, it will output a level signal and transmit it to the main control MCU. The main control MCU will process the level signal after receiving it, so as to complete the corresponding control. The operation is simple and easy, and the design of the rotary cap is rich and varied.

Owner:HUIZHOU CONMO MEDICAL TECH CO LTD

Adhesive-type fine-grained-sandstone relief-like decorative material

InactiveCN109138315AGuaranteed insulation effectEliminate hot and cold bridge phenomenonCovering/liningsCalcium silicateKeel

The invention relates to a decorative structure, in particular to an adhesive-type fine-grained-sandstone relief-like decorative material used for building external walls, external walls of vehicles and ships, and the like. The adhesive-type fine-grained-sandstone relief-like decorative material comprises a base wall body, a keel, fixing screws and thermal-insulation decorative boards, wherein thethermal-insulation decorative boards adhere to the base wall body and the other sides of the thermal-insulation decorative boards are fixedly connected to the keel. The adhesive-type fine-grained-sandstone relief-like decorative material is an environment-friendly thermal-insulation decorative composite board with high compression resistance, water impermeability, moisture resistance, air impermeability, light weight, corrosion resistance, long service life, low thermal conductivity and other excellent properties. The adhesive-type fine-grained-sandstone relief-like decorative material permits high permeation, rapid permeation and deep permeation of ultraviolet (UV) curing permeating agents into a fiber-reinforced calcium silicate board or a fiber cement board to achieve deep cure and film forming and to form a three-dimensional chemical reticular cross-linking reaction with UV putty and UV sealers, thereby solving the problem of adhesion of a decorative surface layer to a base board.The invention also provides a flame-retardant material. The flame-retardant decorative board prepared according to a method provided by the invention meets the requirements of national standards in gluing property and imparts a flame-retardant property to a base material. In addition, the mechanical properties of the base material are not affected, and the formaldehyde emission also reaches abovethe E1 level so as to achieve safety and environment protection. Meantime, the natural texture of wood is maintained and the decorative effect is good.

Owner:高玉涛

Two-piece type wheel

InactiveCN106004241AAvoid the risk of falling off the hubImprove mechanical propertiesRimsBarrel ShapedEngineering

Owner:宁波市镇海维梦思贸易有限公司

Mounting method of wall heat-insulation decoration plate

InactiveCN108661266AGuaranteed insulation effectPrevent mildewCovering/liningsFlooringKeelCoating system

The invention relates to a mounting method of a wall heat-insulation decoration plate. The outer wall plate is connected with a base wall through a keel and composed of surface decoration plate layercladding, an intermediate waterproof glass cotton layer and a moisture-proof aluminum foil veneer. Compared with the prior art, the wall heat-insulation decoration plate has the advantages of being high in heat insulation performance, good in decoration effect, safe, durable, low in cost and the like. According to construction of a traditional outer wall heat-insulation coating system, on-site layered gradual construction is conducted generally, the construction time is long, the process is complex, and construction is affected by the weather factor greatly. The heat-insulation decoration plate is completely subjected to dry construction and completely not affected by the weather or seasons, the mounting mode is simple and quick, and the construction efficiency is twice or more than that of the traditional practice.

Owner:肖桂云

Anti-impact polyurethane surface decorating material

InactiveCN108240074AProduct quality is stableGood insulation performanceCovering/liningsLacquerCement board

The invention discloses an anti-impact polyurethane surface decorating material. Two processes are included. The primer line processing technology process includes the specific steps of (1) fixed-thickness sanding and dust removal; (2) roller coating of a back seal coat and curing for forming of a first UV seal coat layer; (3) two times of roller coating of a UV penetrating agent; (4) infrared leveling; (5) front coating of UV putty and UV curing for forming of a UV putty layer; (6) three times of roller coating of a UV seal coat and separate curing for forming of three second UV seal coat layers; and (7) finish sanding. The finishing coat line roller-coating technology process includes the specific steps of (1) dust removal; (2) roller coating of UV glue for forming of a first UV glue layer; and (3) five times of coating of a UV finishing coat and curing for forming of five UV finishing coat layers. Strong permeation, rapid permeation and deep permeation of a UV curing penetrating agent with a fiber-reinforced calcium silicate board or a fiber cement board can be avoided, films are formed by deep curing, and a three-dimensional chemical meshed crosslinking reaction is achieved with UV putty and UV seal coats so that the problem of adhesion force between a decorating surface layer and a base board can be solved.

Owner:秦春玉

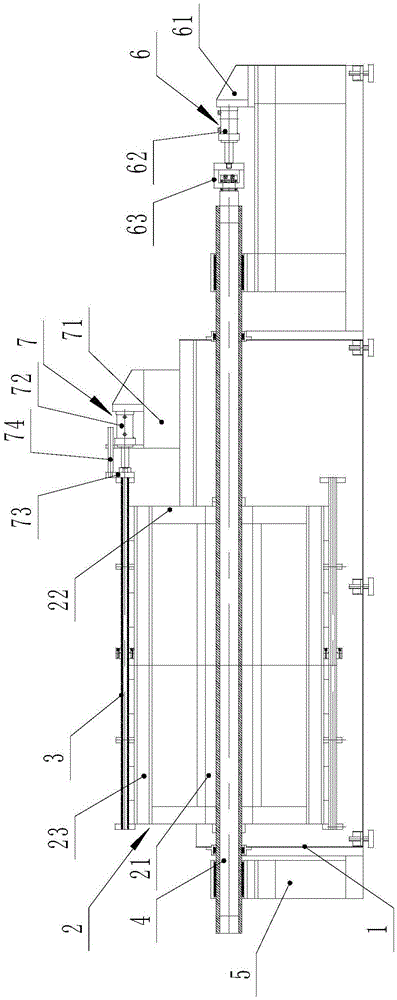

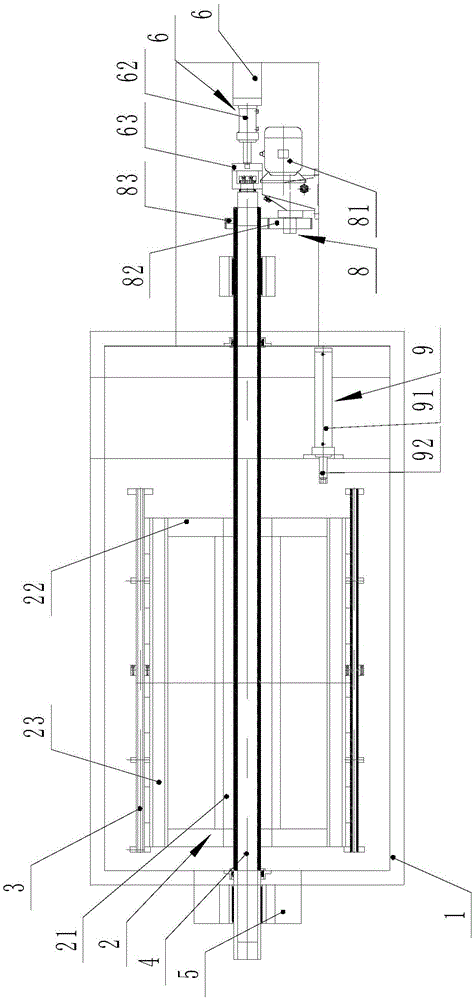

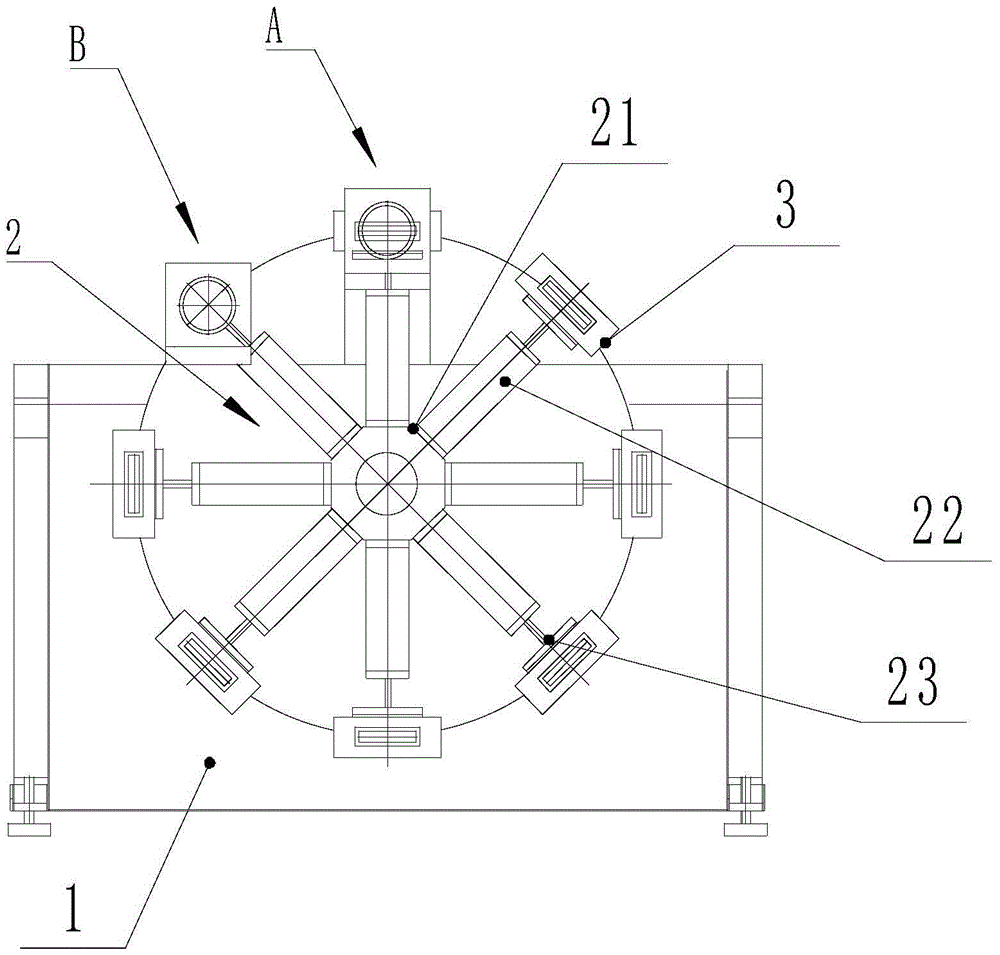

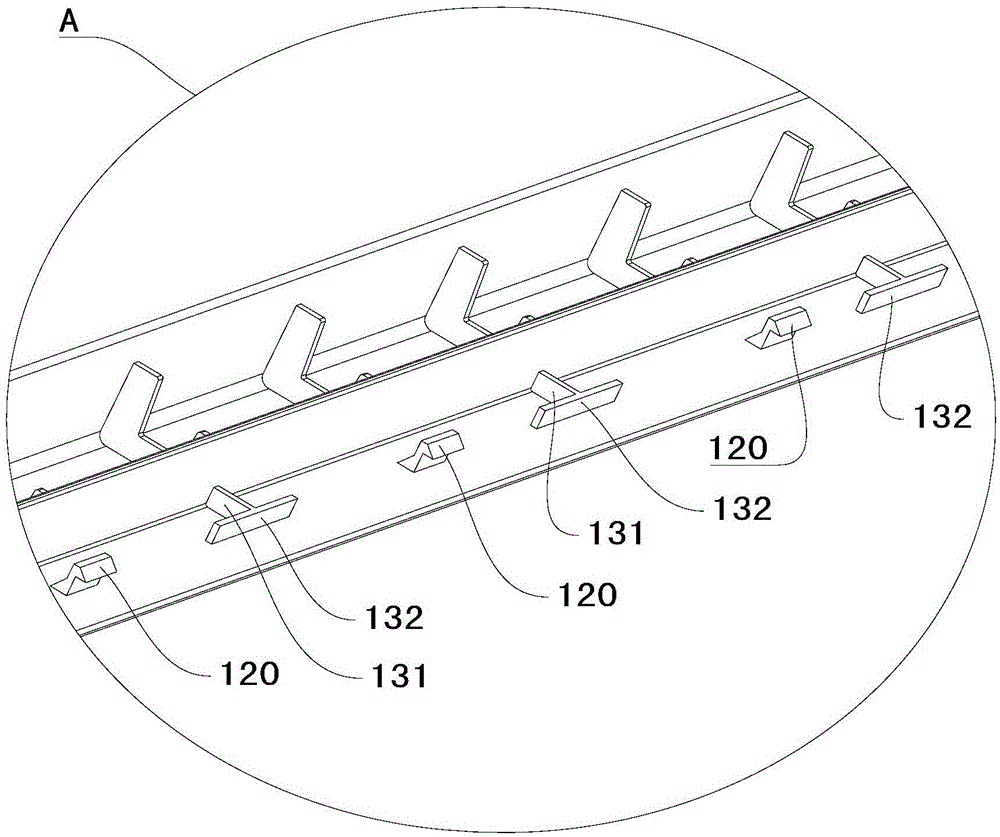

A plastic sheet forming machine

The invention discloses a plastic sheet forming machine. The plastic sheet forming machine comprises a box body, a main shaft, a mold support, at least two forming molds, a forming mold sealing device and a finished product sheet withdrawing device, wherein the main shaft is installed on the box body in a rotating manner, the forming molds are fixed on the mold support, a front opening of each forming mold is used for being matched with an extruder mold head, the mold support is fixed on the main shaft, the forming molds are uniformly and circumferentially distributed relative to the axis of the main shaft, cooling liquid is stored in the box body, the mold support is partially soaked in the cooling liquid, a main shaft rotation drive device is installed on the box body and connected with the main shaft in a transmission manner, a main shaft sliding drive device is installed on the box body and connected with the main shaft in the transmission manner, the forming mold sealing device is installed on the box body, the forming mold sealing device is matched with a rear opening of each forming mold on a forming workstation in a sealing manner or separated from the rear opening of the each forming mold on the forming workstation, and the finished product sheet withdrawing device is installed on the box body and cooperated with the rear opening of each forming mold on an unloading workstation to complete the finished product sheet withdrawing. The forming machine is relatively small in floor occupation area, the forming efficiency of sheets can be improved, and the cost is reduced.

Owner:ZHANGJIAGANG CITY YILI MACHINERY

Natural color sand resin synthesized stone-imitating decoration material

InactiveCN108240085AGuaranteed insulation effectPrevent mildewCovering/liningsThermal insulationGlass wool

The invention relates to a natural color sand resin synthesized stone-imitating decoration material. An outer wallboard is connected with a base wall through keels, and the outer wallboard is composedof a surface decoration board layer coat, a middle waterproof glass wool layer and a moistureproof aluminum foil veneer. Compared with the prior art, the natural color sand resin synthesized stone-imitating decoration material has the advantages of being high in thermal insulation, good in decoration effect, safe, durable, low in cost and the like.

Owner:秦春玉

Top cover for refrigeration device and refrigeration device with the top cover

ActiveCN103499176BChangeable appearanceAppearance is rich and variedDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention discloses a top cover used for a refrigeration device and the refrigeration device provided with the top cover. The top cover used for the refrigeration device comprises a frame and a surface board, wherein a containing hole is formed in the frame and the upper end of the containing hole is open; the surface board is detachably arranged in the containing hole and covers the containing hole. The top cover used for the refrigeration device has the advantages of being rich and diverse in appearance.

Owner:HEFEI HUALING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com