Manufacturing method of outer wall heat-preservation decorating plate with vacuum heat-insulation function

A technology of vacuum heat insulation and external wall insulation, which is applied to floors, coverings/linings, buildings, etc., and can solve the problems of poor adhesion between the paint layer and the board, reduce the production cost of the board, and poor adhesion of the paint layer , to achieve the effect of reducing the overall cost and building load, saving installation costs and time, and improving the sound-absorbing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

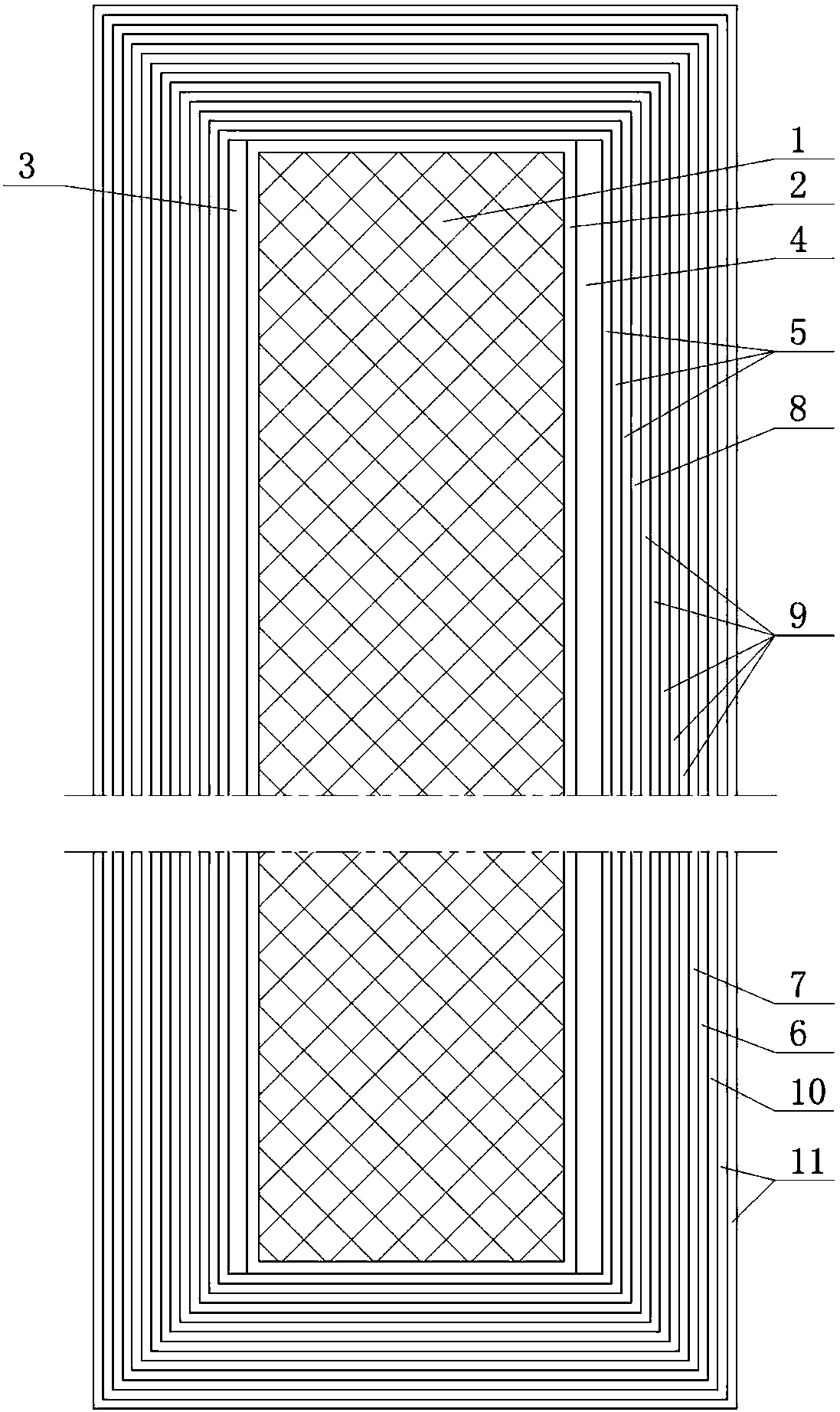

[0032] The exterior wall thermal insulation decorative board with vacuum heat insulation of the present invention comprises a board 1, the front of the board 1 is provided with a UV putty layer 4, the back of the board 1 is provided with a first UV sealing paint layer 3, the board 1, the first The outer periphery of the UV sealing paint layer 3 and the UV putty layer 4 is provided with three layers of the second UV sealing paint layer 5 , and the outside of the second UV sealing paint layer 5 is provided with the first UV adhesive layer 8 and five layers of UV topcoat layer 9 . The outside of the UV topcoat layer 9 is provided with a second UV adhesive layer 7, the outside of the second UV adhesive layer 7 is provided with a bionic film 6, and the outside of the bionic film 6 is provided with two layers of second UV paint layers 11. The second UV sealing paint layer 5 of the third layer is a white primer, and its thickness is 70-110 microns.

[0033] A method for manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com